We may not have the course you’re looking for. If you enquire or give us a call on +43 720 115337 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Efficiency and customer satisfaction are key to staying ahead in today’s competitive market. Have you ever wondered how companies manage to deliver products so quickly and keep everything running smoothly? It all comes down to understanding the difference between Cycle Time vs Lead Time. These two essential metrics help businesses streamline their processes, from starting a task to delivering the final product.

In this blog, we will discuss what Cycle Time vs Lead Time are, how to calculate them, and why they matter so much for your business success. Get ready to uncover the secrets to boosting your productivity and delighting your customers!

Table of Contents

1) What is Cycle Time?

2) What is Lead Time?

3) Differences between Cycle Time and Lead Time

4) How to calculate Cycle Time vs Lead Time

5) Benefits of calculating Cycle time and Lead Time

6) Conclusion

What is Cycle Time?

Cycle Time is a key metric used in Project Management and manufacturing to measure the amount of time it takes to complete one cycle of a process. It starts when the work begins on an item and ends when the item is ready for delivery. It helps organisations identify inefficiencies and optimise processes to improve productivity and reduce costs. In Kanban, Cycle Time is used to measure the efficiency of the workflow and identify bottlenecks.

What Is Lead Time?

Lead Time is the total time it takes from the moment a customer places an order until the final product or service is delivered. It covers the entire process, including order processing, production, and shipping. It includes both the Cycle Time (actual work time) and any waiting time or delays caused by external factors. In Kanban, Lead Time is critical for assessing the overall speed of the process and ensuring timely delivery to customers.

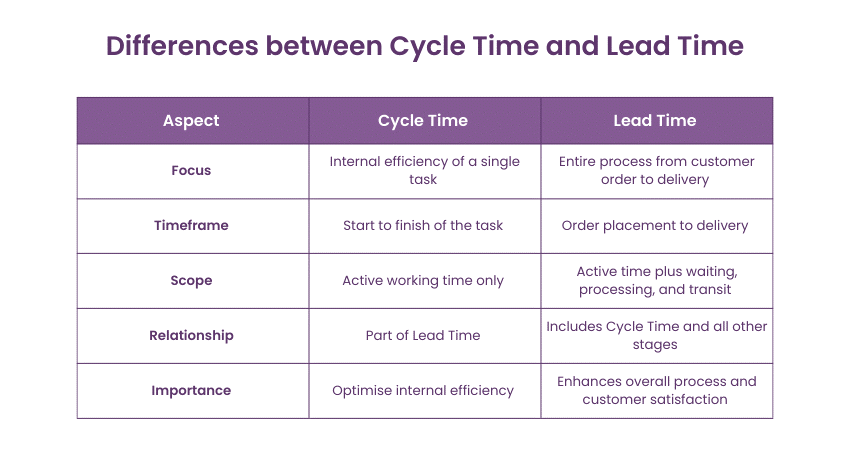

Differences between Cycle Time and Lead Time

Here are some of the differences between Cycle Time and Lead Time:

Focus

Cycle Time measures the internal efficiency of completing a single unit of work. It tracks how long it takes to complete a task from start to finish within the production process.

On the other hand, Lead Time measures the entire process from the customer's perspective. It measures the total time taken from when a customer places an order until the final product or service is delivered.

Scope

Cycle Time includes only the time spent actively working on the task. It does not account for any waiting periods or delays.

On the other hand, Lead Time covers the Cycle Time as well as any additional time spent waiting, processing, or in transit. It accounts for all stages of the process, from initial order placement to final delivery.

Component relationship

Cycle Time is a component of Lead Time. It represents just the active working period within the overall process.

In contrast, Lead Time provides a complete picture of the total time taken for the entire process.

Importance

Cycle Time is essential for assessing the internal efficiency of specific tasks and processes within the production cycle. It helps identify areas where processes can be optimised for faster completion.

On the other hand, Lead Time is vital for improving overall process efficiency and enhancing customer satisfaction. By reducing Lead Time, companies can ensure quicker delivery times, thereby increasing customer satisfaction and gaining a competitive edge.

Transform your workflow with Certified Kanban Practitioner Training – join today!

How to calculate Cycle Time vs Lead Time

Calculating Lead Time and Cycle Time for any project is simple with the right Project Management software. The most common method to calculate these times is using the Cumulative Flow Diagram (CFD).

A CFD is a graph that shows the progress of a project over time. The diagram is divided into segments, each corresponding to a column on a Kanban Board. The basic segments include planned tasks, tasks in progress, and completed tasks, but additional sections can be added to further streamline tracking.

To calculate Lead Time, interpret the data from when a request is added to the backlog, moves through the process, and is completed. The time from the request entering the system to its completion represents the Lead Time.

To calculate Cycle Time, skip the initial backlog phase and start measuring once the work begins. Cycle Time is the time spent per unit of work after it has started.

Transform your workflow with Certified Kanban Practitioner Training – join today!

Benefits of calculating Cycle time and Lead Time

Let's explore some of the advantages of calculating Cycle Time and Lead Time:

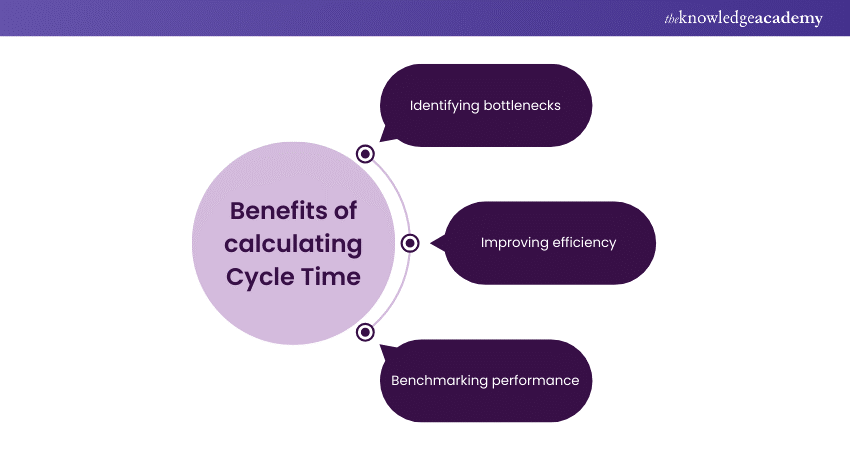

Benefits of calculating Cycle Time:

a) Identifying bottlenecks: By measuring Cycle Time, organisations can pinpoint stages in the process that take longer than expected and address inefficiencies.

b) Improving efficiency: Reducing Cycle Time can lead to faster production rates and lower costs.

c) Benchmarking performance: Cycle Time provides a clear metric to benchmark against industry standards or previous performance.

Benefits of calculating Lead Time:

a) Enhancing customer satisfaction: Shorter Lead Times lead to faster delivery, improving customer satisfaction and loyalty.

b) Better inventory management: Understanding Lead Time helps in managing inventory levels more effectively, reducing overstock or stockouts.

c) Competitive advantage: Companies that can deliver products faster than their competitors can gain a significant market advantage.

Conclusion

Understanding Cycle Time vs Lead Time is important for making processes better and keeping customers happy. Cycle time shows how long it takes to finish one task, while Lead Time covers the entire process from order to delivery. By measuring these times, businesses can find and fix slow spots, work more efficiently, and improve overall performance.

Learn Kanban process and principles with our Certified Kanban Foundation and Practitioner Training – join today!

Frequently Asked Questions

Reducing Lead Time is important because it helps deliver projects faster, making customers happy sooner. It also gives companies an edge by allowing them to respond quickly to market demands and cut down on costs.

Reducing Lead Time is important because it helps deliver projects faster, making customers happy sooner. It also gives companies an edge by allowing them to respond quickly to market demands and cut down on costs.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Kanban Training , including the Certified Kanban Foundation and Practitioner Training, Certified Kanban Foundation Training and Certified Kanban Practitioner Training. These courses cater to different skill levels, providing comprehensive insights into Kanban Roles.

Our Business Improvement Blogs cover a range of topics related to Kanban, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Project Management skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Certified Kanban Foundation Training

Certified Kanban Foundation Training

Mon 6th Jan 2025

Mon 7th Apr 2025

Mon 4th Aug 2025

Mon 3rd Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please