We may not have the course you’re looking for. If you enquire or give us a call on +61 272026926 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Have you ever felt like there is a better way to do things within your organisation? You may have noticed inefficiencies, bottlenecks, or quality issues that hold your team back from reaching its full potential. Many businesses face similar challenges daily, so they use Lean Six Sigma, a proven methodology that can help you tackle these issues. By understanding How to Apply Lean Six Sigma, you can overcome these challenges and enhance efficiency.

In this blog, you will learn How to Apply Lean Six Sigma with step-by-step instructions. Further, you will also learn about its advantages and principles. Let's dive in!

Table of Content

1) What is Lean Six Sigma?

2) How to Apply Lean Six Sigma in your organisation?

3) Principles of Lean Six Sigma for improving operations

4) Advantages of implementing Lean Six Sigma

5) Conclusion

What is Lean Six Sigma?

Lean Six Sigma is a powerful technique that combines two distinct approaches to process improvement: Lean Manufacturing and Six Sigma. Lean focuses on reducing waste and maximising efficiency by streamlining processes and eliminating non-value-added activities. It aims to deliver products or services with the highest possible value to customers while minimising resources, time, and effort.

On the other hand, Six Sigma is a data-driven approach that helps businesses reduce defects and variations in processes to achieve near-perfect quality. It emphasises statistical analysis and problem-solving techniques to find and address the root causes of issues.

Overall, Lean Six Sigma provides a comprehensive framework for organisations to optimise operations, enhance quality, and drive continuous improvement.

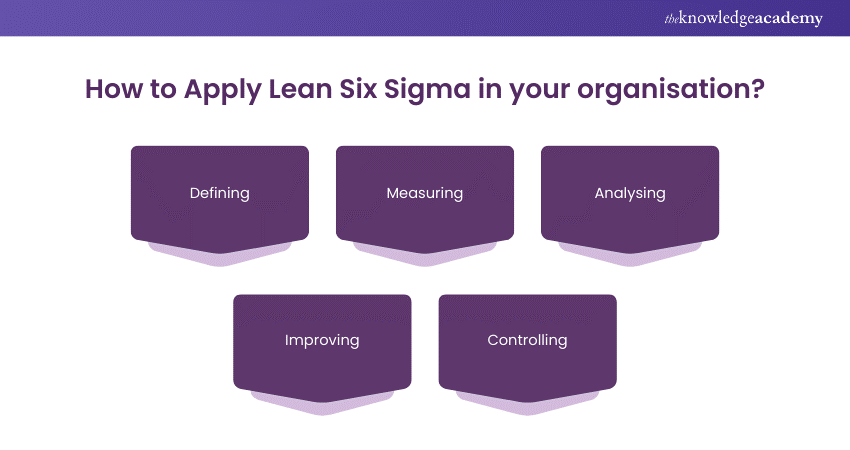

How to Apply Lean Six Sigma in your organisation?

Here is a breakdown of the key steps involved in How to Apply Lean Six Sigma in your company:

1) Defining

This is the foundation for the entire Lean Six Sigma journey. So, begin it by clearly defining the problem or opportunity for improvement within your organisation.

2) Measuring

Quantify the current state of your processes to establish a baseline for improvement. Collect relevant data and metrics to analyse the performance accurately.

3) Analysing

Identify the root causes of inefficiencies or defects through Data Analysis and process mapping. This step is crucial for devising effective solutions.

4) Improving

Implement solutions and process modifications to address the identified root causes. Focus on maximising efficiency and eliminating waste.

5) Controlling

Continuously measure performance and make adjustments as necessary. So, establish controls and monitoring systems to sustain the improvements achieved.

Improve organisational efficiency with our Lean Six Sigma Yellow Belt Training – join now!

Principles of Lean Six Sigma for improving operations

Lean Six Sigma is founded on a set of principles that guide organisations in achieving operational excellence and continuous improvement. Let's delve deeper into each principle:

1) Execute rapid projects with well-defined objectives

Successful Lean Six Sigma initiatives begin with clearly defined project objectives. These objectives should be specific, measurable, achievable, relevant, and time-bound (SMART). By setting well-defined objectives, teams can focus their efforts effectively and achieve tangible results within a reasonable timeframe. Rapid project execution ensures that improvements are implemented swiftly, minimising downtime and maximising the impact on organisational performance.

2) Prioritise customer focus

Central to Lean Six Sigma is the concept of customer-centricity. Businesses must prioritise understanding and meeting the needs of their customers. By talking to customers, listening to their feedback, and studying market trends, businesses can find ways to make things better.

This helps them create products and services that customers really love. A relentless focus on the customer ensures that organisational efforts are aligned with enhancing customer satisfaction and loyalty.

3) Identify the value stream and address the root cause of issues

Organisations need to understand every step to make things work smoother, from when a customer asks for something to when they receive the final product or service. By mapping out the value stream, teams can identify areas of waste, inefficiency, and variation.

Instead of merely treating symptoms, Lean Six Sigma emphasises addressing the root causes of problems. By employing tools such as root cause analysis, organisations can implement targeted solutions that lead to sustainable improvements in process performance.

4) Foster a collaborative and sustainable work environment

Working together is crucial for Lean Six Sigma to succeed. When organisations create an environment where everyone collaborates and shares ideas, they can benefit from their employees' collective expertise and insights. Cross-functional collaboration encourages knowledge sharing, innovation, and continuous learning.

Moreover, sustainability is paramount in Lean Six Sigma. Organisations must establish systems and processes to ensure that improvements are sustained over time. By embedding Lean Six Sigma principles into the organisational culture, businesses can create a work environment where continuous improvement is not just a project but a way of life.

5) Eliminate wasteful processes

Waste refers to any activity or process that uses resources but doesn't contribute value to the customer. Lean Six Sigma aims to eliminate waste in all its forms, including overproduction, defects, waiting, unnecessary transportation, inventory, motion, and overprocessing.

By streamlining processes and eliminating non-value-added activities, companies can improve efficiency, reduce costs, and enhance overall productivity. Continuous efforts to identify and eliminate waste are essential for sustaining Lean Six Sigma improvements and driving long-term success.

Elevate your Lean Six Sigma skills with our Lean Six Sigma Certification Training - join today for enhanced process excellence!

Advantages of implementing Lean Six Sigma

Implementing Lean Six Sigma offers numerous benefits, including:

Implementing Lean Six Sigma in your organisation can lead to a wide array of advantages that positively impact various aspects of your business. Here's a detailed look at the benefits:

1) Improved efficiency

Lean Six Sigma streamlines processes and eliminates waste, leading to smoother operations and reduced time and effort spent on tasks. This means that we can get more done in less time when things work better.

2) Enhanced quality

Lean Six Sigma helps make products or services better by finding and fixing the root causes of problems. This leads to fewer errors, reduced rework, and, ultimately, higher customer satisfaction.

3) Cost reduction

One of the major goals of Lean Six Sigma is to minimise unnecessary costs by eliminating waste and inefficiencies. This can result in significant savings for the organisation, both in terms of direct costs and indirect costs associated with poor quality or inefficient processes.

4) Increased productivity

By optimising processes and focusing on value-added activities, Lean Six Sigma enhances productivity across the organisation. Employees can achieve more in less time, leading to higher output and better resource utilisation.

5) Better decision-making

Lean Six Sigma relies on data-driven analysis to identify problems, evaluate solutions, and measure results. This helps organisations make smart decisions using real data rather than guesses or intuitions.

6) Strengthened customer relationships

By always giving customers top-notch products or services that meet or even go beyond their expectations, Lean Six Sigma builds trust and keeps customers coming back. This strengthens the organisation's reputation and fosters long-term relationships.

7) Competitive advantage

Organisations that successfully implement Lean Six Sigma gain a competitive edge in the marketplace. They can offer better quality products or services at competitive prices, positioning themselves as industry leaders.

8) Empowered employees

Engaging employees in Lean Six Sigma initiatives empowers them to take ownership of their work and contribute to process improvements. This fosters a culture of accountability, innovation, and continuous learning.

9) Continuous improvement culture

Lean Six Sigma encourages a mindset of continuous improvement, where employees are constantly seeking out opportunities to enhance processes and drive innovation. This culture of continuous improvement is essential for staying competitive in today's rapidly changing business environment.

10) Sustainable growth

By systematically identifying and addressing inefficiencies, Lean Six Sigma lays the foundation for sustainable growth. Businesses that use Lean Six Sigma can quickly adjust to changes in the market and stay ahead of competitors in the long run.

Overall, implementing Lean Six Sigma offers many advantages, from improved efficiency to strengthened customer relationships. These benefits make Lean Six Sigma a valuable tool for organisations striving for excellence in today's dynamic business landscape.

Learn problem-solving skills through Lean methodologies with our Lean Training. Join today!

Conclusion

Knowing How to Apply Lean Six Sigma can significantly affect how well a business operates. Companies can work much better by following clear steps like defining goals, measuring progress, fixing problems, making improvements, and keeping things on track. So, it's not just about understanding Lean Six Sigma; it's about implementing it to improve things for everyone involved.

Learn key leadership behaviours with our Six Sigma Master Black Belt Courses. Sign up now!

Frequently Asked Questions

Six Sigma is applied through a structured methodology involving Define, Measure, Analyse, Improve, and Control (DMAIC) phases aimed at reducing defects and improving process efficiency.

Six Sigma is a data-driven approach for process improvement, widely used across industries such as manufacturing, healthcare, finance, and more to enhance quality and performance.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Lean Six Sigma Certification Courses, including Lean Six Sigma Green Belt, Lean Six Sigma Yellow Belt, and Lean Six Sigma Black Belt. These courses cater to different skill levels, providing comprehensive insights into Lean Six Sigma Belts.

Our Business Improvement Blogs cover a range of topics related to Lean Six Sigma, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Lean Six Sigma skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please