We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Artificial Intelligence (AI) is the ability of machines to make decisions based on their interpretation of the data they analyse. AI simply makes the machines smarter. Businesses across different sectors have started implementing AI in their operations. Manufacturing is one such industry where the role of AI is increasing rapidly. AI in Manufacturing involves using different complex technologies to improve the efficiency of different manufacturing processes.

According to Markets and Markets the global share of AI in Manufacturing is expected to reach GBP 12.6 billion by 2027. Read this blog to learn the role of Artificial Intelligence in Manufacturing, its pros and cons and examples of its implementation in this industry.

Table of Contents

1) What is Artificial Intelligence in Manufacturing?

2) Benefits of Artificial Intelligence in Manufacturing

a) Artificial Intelligence in Manufacturing Industry Examples

3) Disadvantages of Artificial Intelligence in Manufacturing

4) Conclusion

What is Artificial Intelligence in Manufacturing?

Artificial Intelligence in Manufacturing means automating operations and finding defects in production processes. AI can transform the Manufacturing industry. The reason is simple. AI can receive and process different types of data on a large scale. It can receive data from humans, i.e., manually and from machines, i.e., automatically. This ability of AI has helped the Manufacturing industry improve and increase its operations significantly. This increase can be seen not only in terms of quantity but quality also. It is not possible to ensure the same standard of uniformity and quality as manual manufacturing operations, but this is where AI is taking over the industry. It provides the best quality work with consistent quality that meets both the company’s and regulatory bodies’ norms. AI has also helped enhance production designs, one of the most essential parts of the manufacturing sector.

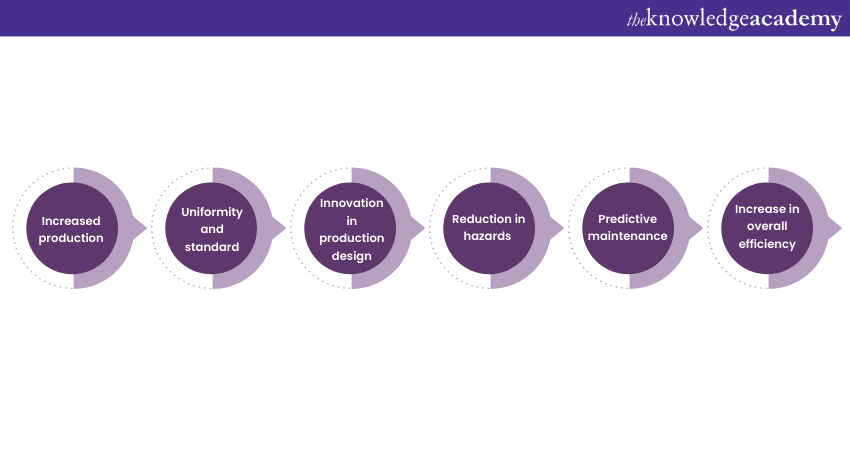

Benefits of Artificial Intelligence in Manufacturing

The most visible result of using AI in Manufacturing is that with the help of Robotic Process Automation, AI has made it possible to increase production significantly. AI has increased both the speed and quantity of production and the quality. Artificial Intelligence in Manufacturing has proved very helpful in detecting defects and hence improving the quality of the products. If done manually, it’s a time taking process and involves many levels of quality-check. With the help of AI, operational time has been reduced considerably.

But how has AI helped in the increase of production? Humans are not generally productive for more than five hours a day. They need breaks and time off for their work-life balance. But AI can work 24x7. Machines can work continuously. They can also perform multiple tasks simultaneously.

It’s not an easy task to manually take care of manufacturing defects in complicated and smaller goods like microchips. AI has simplified this process. AI can process and interpret vast data volumes, from designing to the final production. One of the key advantages of using AI is that it can gather and analyse large amount of data in a relatively shorter period of time. This is the reason the Manufacturing industry is harnessing the benefits of AI.

Check out our Artificial Intelligence (AI) For Project Managers Course!

Uniformity and standard

Manufacturing is a field that requires great attention to detail and a uniform standard. Suppose a company manufactures toys; all its products should be identical. Again, it’s not humanely possible to maintain the same standard and quality in mass-level Manufacturing. Quality assurance is a time-consuming process and requires many highly skilled resources when done manually. Today, image processing technologies can automatically check if a particular item is defective or not. AI is of great use in this regard.

Production design

Another great contribution of AI is that it has helped enhance production designs. These are an integral part of the Manufacturing sector. Engineers and designers have to work continuously in search of better product designs. AI technology has brought revolutionary changes in this field. The automobile industry and aviation sectors are the best examples. Self-driving cars have become a reality due to the AI technology.

These days, AI has empowered the Manufacturing sector to make a virtual replica of their products. This is known as the “digital twin.” In the generative design software system, certain inputs are provided, such as the proposed raw materials, product dimensions and weight, manufacturing methods, cost and other resource constraints, etc. Using these parameters; the AI algorithm generates few design permutations. This can help manufacturers have a better understanding of their products.

Safety concern

Human life is of utmost importance. Sometimes the Manufacturing sector poses a threat to human lives. AI technology has helped reduce this risk also. For example, AI-enabled access control reduces potential risks when the work is hazardous (like in the iron and steel industry, where people have to work near furnaces). It can also detect and prevent the leakage of toxic substances.

Predictive maintenance

Predictive maintenance is another area where AI has contributed a lot. Manufacturers use AI technology to identify potential damages or induced accidents by examining sensor data. AI has also made scheduled automated maintenance and repairs possible. This helps check potential breakdowns of machines. It not only lowers the cost but also increases productivity.

Moreover, AI can predict manufacturing yields and provide price comparisons for a product also. High accuracy in yield prediction can help companies plan better, while price comparison with the competitors helps in marketing strategies.

Energy efficiency

In recent times, the energy crisis has emerged as one of the biggest challenges for the manufacturing sector. AI-automated energy management can help companies cut their cost to a large extent. Today, AI can analyse energy usage and cut the cost of running a production unit based on its analysis. This saving can be utilised for resources, innovation or on marketing.

Building “connected factories” or “smart factories”

Connected or smart factories use sensors and cloud-based storage to analyse real-time data. These factories help provide real-time shop floor visibility, monitor assets, establish remote and contactless systems, enable real-time interventions and scale production capacity. One of General Electric Company’s (GE) plants is a good example of this. This is known as “Brilliant Factory”. This unit witnessed a 45%-60% increase in OEE (overall equipment effectiveness) in the connected machines.

Learn the details of Machine Learning with our Machine Learning Training course!

Cobots

Robots are known to perform specific tasks but collaborative robots or ‘cobots’ can do various tasks simultaneously. In Manufacturing units, these cobots can work on tasks requiring heavy lifting or locating and retrieving items in a large warehouse. This application is especially useful in automobile industries.

The Manufacturing industry requires extensive logistics services. With the help of AI, several logistics-related tasks have been automated in production units. It has boosted efficiency and reduced costs. Manufacturing units have several routine tasks that can be automated using AI technology. It can save a considerable number of man-hours annually.

Explore new career opportunities in AI with our Artificial Intelligence & Machine Learning courses!

Artificial Intelligence in Manufacturing Industry Examples

Now that we have seen what is AI technology and how it is helping the manufacturing industry, let us have a look at some case studies to get a better idea. Here are a few examples of Artificial Intelligence in Manufacturing:

a) Robotic employees have been deployed by a Japanese group of companies “Fanuc” that provides automation products and services such as robotics and computer numerical control wireless systems. These robots can manufacture crucial motor- parts, run factory floor equipment and also monitor continuous operations.

b) German automobile manufacturer “Porsche” is another good example that has benefited from the use of AI in manufacturing. The company uses autonomous guided vehicles (AGVs) for the transport of motor-parts from one processing station to the other, without any human intervention. It has helped the company’s employees during the pandemics like situations.

c) The third example is the German multinational manufacturer of luxury vehicles “Bayerische Motoren Werke” (BMW). This company uses automated image recognition for quality checks and inspections. This has helped the company detect defects and achieve high level of precision in manufacturing.

d) Another good example of AI in manufacturing is “Rockwell Automation”. It has adopted smart manufacturing by wielding AI to top-to-bottom manufacturing processes. The company uses predictive maintenance to forecast potential risks. It also helps the company to adopt proactive measures to preserve product quality.

Learn more with Artificial Intelligence (AI) For Business Analysts Course!

Disadvantages of Artificial Intelligence in Manufacturing

Although AI is a game changer because of its use in the Manufacturing industry, it has some challenges. We know that AI is totally based on advanced supercomputing technology. Installation of such systems demands huge investment. Even if the technology cuts the labour costs later, the implementation costs are high. It also requires continued maintenance. Smaller industries may sometimes find it difficult to deal with this.

Companies must train their employees first to get the maximum of AI technology. The shortage of AI skills and the unavailability of the required expertise make it difficult. Companies need to invest in employees’ trainings to upgrade their skills.

The second biggest challenge with AI in manufacturing is related to cybersecurity. AI technology works on the interpretation of lots and lots of data. Any technical leakage, breach or mishandling of data can cause huge monetary and reputation losses to the companies.

Conclusion

We have seen what Artificial Intelligence is in Manufacturing and how it has helped transform the sector. We know AI technology comes with challenges, but today almost all industries use AI to enhance their businesses, and the manufacturing sector is no exception. In today’s era of global competition, AI has helped companies harness their full potential.

Refer to our Deep Learning Training course for more details!

Frequently Asked Questions

Upcoming Data, Analytics & AI Resources Batches & Dates

Date

Introduction to AI Course

Introduction to AI Course

Fri 24th Jan 2025

Fri 28th Mar 2025

Fri 23rd May 2025

Fri 25th Jul 2025

Fri 26th Sep 2025

Fri 28th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please