We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Are you looking to transform your business operations and boost efficiency? Understanding the benefits of Lean Management can revolutionise how your organisation operates. This approach focuses on maximising value while minimising waste, leading to streamlined processes and improved productivity.

Imagine a workplace where waste is eliminated, processes are optimised, and continuous improvement is the norm. With Lean Management, you can achieve enhanced efficiency and empower your employees to contribute to a culture of excellence.

Read this blog to discover the Benefits of Lean Management and see how it can help your business thrive. Embrace this approach to drive significant improvements in your operational performance.

Table of Contents

1) What is Lean Management?

2) 12 Benefits of Lean Management

a) Improved Priority Shift Management

b) Reduced Waste

c) Boost Team Morale

d) Enhanced Efficiency

e) Better Stakeholder Visibility

f) Customer Focus and Satisfaction

g) Increased Efficiency and Productivity

h) Improved Lead Time

i) Employee Engagement and Empowerment

j) Cost Reduction

3) Conclusion

What is Lean Management?

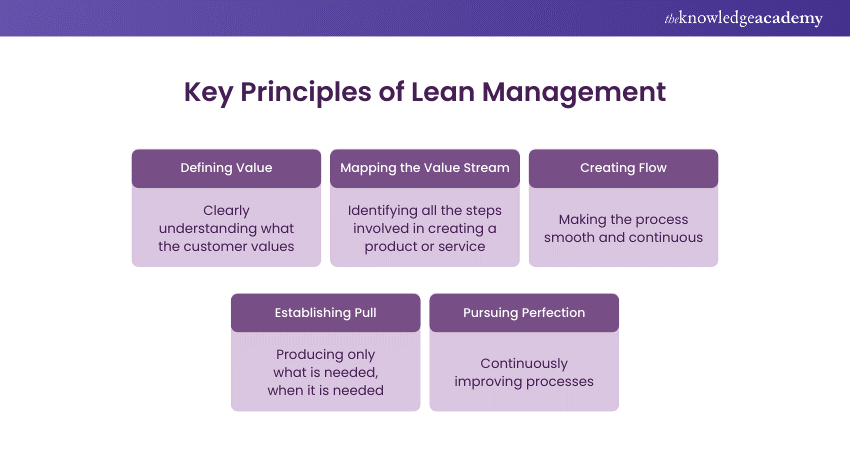

Lean Management, promoted by the Kaizen Institute, aims to achieve excellence by eliminating waste. This approach helps businesses gain a competitive edge in today’s efficiency-driven market. Lean Management focuses on creating customer value while optimising resources.

Lean Management systematically improves processes by removing waste in all areas of the company. It aims to increase quality, reduce lead times, and cut costs. The approach values the customer’s perspective and encourages continuous improvement. It involves all employees, from operators to executives.

12 Benefits of Lean Management

Implementing Lean Management principles can lead to numerous benefits for an organisation, improving various aspects of operations and overall performance. Here are twelve key benefits of Lean Management:

1) Improved Priority Shift Management

Lean Management helps organisations adapt quickly to changing priorities. By focusing on essential tasks and eliminating non-value-added activities, teams can efficiently shift their focus to the most critical tasks, ensuring that resources are allocated where they are needed most.

2) Reduced Waste

A core principle of Lean Management is the identification and elimination of waste in all forms, such as overproduction, waiting times, excess inventory, and unnecessary processes. This reduction leads to more efficient operations and better use of resources.

3) Boost Team Morale

Lean Management involves employees at all levels in the continuous improvement process. This inclusion boosts morale by making team members feel valued and empowered to contribute to the organisation's success.

4) Enhanced Efficiency

By streamlining processes and eliminating waste, Lean Management significantly enhances operational efficiency. This improvement leads to faster production times, reduced costs, and increased output.

Kickstart your Lean Management journey with our Certified Lean Foundation Course - Sign up today!

5) Better Stakeholder Visibility

Lean practices promote transparency and clear communication. Improved stakeholder visibility means that everyone, from employees to management to external stakeholders, has a better understanding of processes and progress, leading to more informed decision-making.

6) Customer Focus and Satisfaction

Lean Management places a strong emphasis on understanding and meeting customer needs. By delivering higher quality products and services more efficiently, organisations can enhance customer satisfaction and loyalty.

7) Increased Efficiency and Productivity

Lean principles help identify and eliminate inefficiencies, leading to increased productivity. Teams can accomplish more with the same or fewer resources, driving better overall performance.

8) Improved Lead Time

Streamlined processes and reduced waste result in shorter lead times. Organisations can deliver products and services to customers more quickly, improving responsiveness and competitiveness.

9) Employee Engagement and Empowerment

Lean Management fosters a culture of continuous improvement where employees are encouraged to suggest and implement improvements. This engagement leads to higher job satisfaction and a more committed workforce.

10) Cost Reduction

By eliminating waste and improving efficiency, Lean Management helps organisations reduce operational costs. Lower costs can lead to higher profitability and the ability to invest in further growth and development.

Enhance your Business Improvement skills with our Lean Training- Register today!

11) Positive Corporate Culture

The emphasis on continuous improvement and employee involvement in Lean Management fosters a positive corporate culture. Organisations that prioritise Lean principles tend to have more collaborative, innovative, and motivated work environments.

12) Quality Improvement

Lean Management focuses on delivering high-quality products and services. By systematically identifying and addressing defects and inefficiencies, organisations can improve their quality standards and meet customer expectations consistently.

Implementing Lean Management principles can transform an organisation, leading to significant improvements in efficiency, productivity, and overall performance. These twelve benefits highlight the comprehensive impact of Lean Management on both operational processes and corporate culture.

Conclusion

The benefits of Lean Management are extensive, including reduced waste, increased efficiency, and continuous improvement. It boosts productivity, employee morale, and customer satisfaction while reducing costs. Implementing Lean principles leads to better visibility, a positive culture, and long-term organisational success.

Become a master of Lean Management with our Certified Lean Practitioner Course- Register now!

Frequently Asked Questions

How Does Lean Management Reduce Costs for Businesses?

Lean Management reduces costs by streamlining processes and eliminating waste. By focusing on efficiency, it minimises unnecessary steps, reduces resource consumption, and enhances productivity. This leads to lower operational costs, reduced inventory expenses, and increased overall profitability for businesses.

Can Lean Management Improve Product or Service Quality?

Yes, Lean Management improves product or service quality by emphasising continuous improvement and defect reduction. It involves regularly assessing processes, implementing best practices, and involving employees in quality enhancement initiatives. This focus on quality ensures that products and services meet or exceed customer expectations consistently.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 3,000 online courses across 490+ locations in 190+ countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are the Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various Lean Training , including the Introduction to Lean, Certified Lean Foundation, and Certified Lean Practitioner. These courses cater to different skill levels and provide comprehensive insights into Lean Principles.

Our Business Improvement Blogs cover a range of topics related to Lean Management, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Lean Management skills. The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Introduction to Lean

Introduction to Lean

Fri 16th May 2025

Fri 5th Sep 2025

Fri 5th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please