We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Digital Twin are not just a buzzword. They are a powerful technology that can revolutionise various industries and domains, by creating virtual replicas of physical objects, systems, and processes. With the Digital Twin Benefits, you can access real-time data, insights, and predictions about the performance, efficiency, and quality of your assets and operations.

You can also simulate and optimise different scenarios and alternatives, and achieve various benefits, such as reduced costs, increased sales, improved customer satisfaction, and more. In this blog, we will give you a complete overview of the Digital Twin Benefits, and how you can leverage them for your business. Happy reading!

Table of Contents

1) What is a Digital Twin?

2) Benefits of Digital Twin

a) Enhancement of customer contentment

b) Elevated product excellence

c) Decreased product development duration

d) Provide guidance and impetus for sustainability endeavours

e) Amplify adaptability and durability within the supply chain

f) Enable the establishment of innovative business models

g) Catalyse operational effectiveness

h) Increase and Improve productivity

3) Conclusion

What is a Digital Twin?

A Digital Twin is a virtual representation of a physical object, system, or process. It mirrors the real-world entity in digital form, allowing for real-time monitoring, analysis, and simulation. It integrates data from various sources like sensors, IoT devices, and historical records to create a dynamic, interactive model.

Digital Twin find applications across diverse industries including manufacturing, healthcare, automotive, and smart cities. They enable predictive maintenance, performance optimisation, and scenario testing, thereby enhancing efficiency and decision-making. By simulating real-world scenarios, Digital Twin facilitate innovation, cost reduction, and improved outcomes in fields ranging from product design and production to urban planning and infrastructure management.

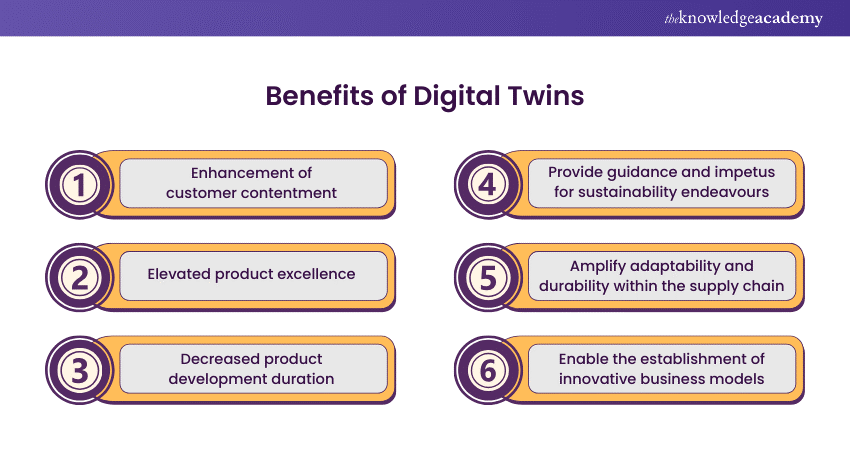

Benefits of Digital Twin

Digital Twin can provide a wide range of benefits for the supply chain industry, such as:

1) Enhancement of customer contentment

Digital Twin can help improve customer satisfaction by providing personalised and customised products and services. By using data from sensors, feedback, and preferences, Digital Twin can create a better understanding of customer needs and expectations and deliver solutions that meet or exceed them.

2) Elevated product excellence

Digital Twin can help improve product quality by enabling faster and more accurate testing, validation, and verification. By simulating different scenarios and conditions, Digital Twin can identify and resolve potential issues and defects before they affect the physical product. Digital Twin can also help optimise product design and performance and reduce waste and errors.

3) Decreased product development duration

Digital Twin can help reduce product development time by accelerating and streamlining the design, prototyping, and manufacturing processes. By using digital models and simulations, Digital Twin can eliminate the need for physical prototypes and trials and enable faster iterations and feedback. Digital Twin can also help reduce costs and risks associated with product development.

4) Provide guidance and impetus for sustainability endeavours

Digital Twin can help promote sustainability by enabling more efficient and eco-friendly use of resources and energy. By monitoring and analysing the environmental impact of products and processes, Digital Twin can help identify and implement ways to reduce emissions, waste, and consumption. Digital Twin can also help support green initiatives and compliance with regulations and standards.

Elevate your industry expertise with our Digital Twin Course. Sign up today!

5) Amplify adaptability and durability within the supply chain

Digital Twin can help enhance agility and resilience within the supply chain by enabling real-time visibility and control over the flow of materials, goods, and information. By using data from sensors, RFID, and GPS, Digital Twin can track and trace the location, status, and condition of assets and inventory, and optimise logistics and operations. Digital Twin can also help prevent and mitigate disruptions and risks within the supply chain.

6) Enable the establishment of innovative business models

Digital Twin can help create new business opportunities and revenue streams by enabling new ways of delivering value and creating value propositions. By using data and insights from Digital Twin, businesses can offer new products and services, such as predictive maintenance, performance optimisation, and remote assistance. Digital Twin can also help create new markets and segments and enhance customer loyalty and retention.

Explore cutting-edge technologies with our Advanced Technologies Courses for a future-ready skill set. Elevate your expertise today!

7) Catalyse operational effectiveness

Digital Twin can help improve operational efficiency by enabling smarter and faster decision making and action taking. By using data and analytics from Digital Twin, businesses can gain a deeper and broader understanding of their operations and performance and identify and implement improvements and optimisations. Digital Twin can also help automate and orchestrate processes and workflows and increase productivity and quality.

8) Increase and Improve productivity

Digital Twin can help boost productivity by enabling more effective and collaborative work and communication. By using digital platforms and tools, Digital Twin can facilitate remote and distributed work, and enable seamless and secure data sharing and access. Digital Twin can also help foster innovation and creativity and empower employees and teams.

Conclusion

In this blog, we have discussed how Digital Twin can simulate, monitor, and optimise the performance of physical objects, systems, or processes. We have also explored the various Digital Twin Benefits, such as enhancing customer satisfaction, product quality, sustainability, supply chain, business models, operational efficiency, and productivity.

Explore the future of technology with our Introduction to Virtualisation Technologies Course. Join now for advanced skills and hands-on expertise!

Frequently Asked Questions

A Digital Twin is a virtual representation of a physical object, system, or process that can be used to simulate, monitor, and optimise its performance. A Digital Twin is created by collecting data from sensors, IoT devices, ERP systems, and other sources, and using advanced analytics, artificial intelligence, and cloud computing to process and visualise it.

There are different types of Digital Twin, depending on the level of complexity and scope of the physical entity they represent. Some of the common types of Digital Twin are:

a) Product Digital Twin

b) Process Digital Twin

c) System Digital Twin

d) Supply Chain Digital Twin

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

Discover Advanced Technologies Courses with The Knowledge Academy, offering Reverse Engineering courses, Virtual Reality training and LTE Fundamentals training. Designed for diverse skill levels, these courses provide a comprehensive understanding of Advance Technologies methodologies.

Upcoming Advanced Technology Resources Batches & Dates

Date

Virtual Reality (VR) Training

Virtual Reality (VR) Training

Fri 29th Nov 2024

Fri 10th Jan 2025

Fri 14th Mar 2025

Fri 9th May 2025

Fri 11th Jul 2025

Fri 12th Sep 2025

Fri 14th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please