We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Feeling bogged down by project delays and inefficiencies? Lean Kanban could be your game-changer! By visualising workflows on a Kanban board, Lean Kanban simplifies Project Management, quickly spots bottlenecks, and promotes continuous improvement.

This method optimises every step of your process for maximum efficiency. Embrace Lean Kanban today to transform your Project Management strategy, boost productivity, and achieve remarkable results. Explore this blog to discover how Lean Kanban can streamline your workflows and enhance your team’s performance now!

Table of Contents

1) What is Lean Kanban Methodology?

2) Benefits of Lean Kanban

3) Lean Kanban: Driving Improvement and Respect for People

4) How to Implement Lean Kanban in Three Easy Steps

5) Conclusion

What is Lean Kanban Methodology?

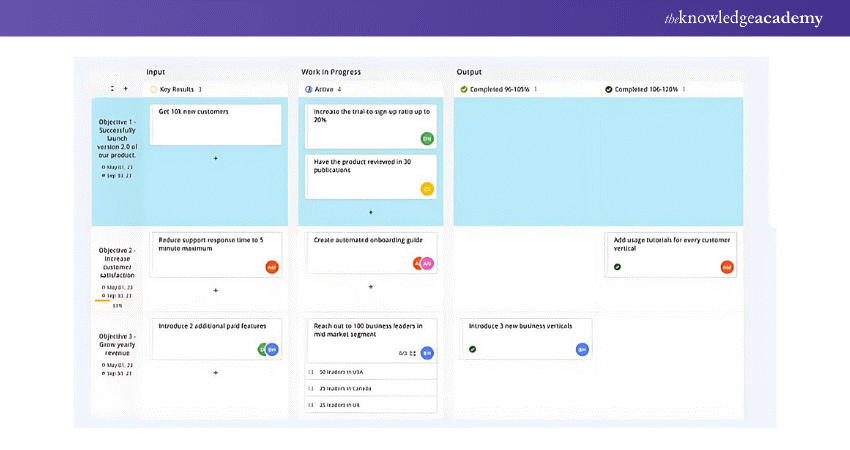

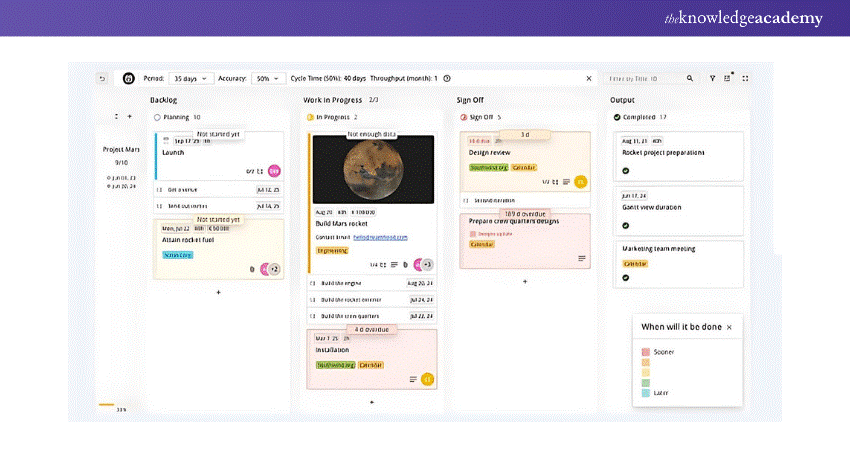

Lean Kanban methodology is a Project Management approach that integrates Lean principles with Kanban practices to enhance efficiency and productivity. It focuses on visualising workflows through Kanban Boards, which display tasks in various stages of completion. This allows teams to track progress and identify bottlenecks in real-time.

By focusing on continuous improvement, Lean Kanban aims to optimise processes, reduce waste, and streamline project execution. This methodology helps teams adapt quickly to changes, improve workflow visibility, and maintain a steady pace of work, ultimately leading to more effective and responsive Project Management.

Benefits of Lean Kanban

With a Kanban system, teams not only complete tasks but also continually refine their processes. This focus on spotting issues and striving for continuous improvement is why Kanban is often seen as a Lean methodology.

The Lean Kanban approach offers several benefits:

1) Understanding Where Teams Are Spending Time

Lean Kanban helps teams track how their time is spent. Most Kanban tools provide productivity data that reveals where time is allocated, allowing teams to optimise their efforts.

2) Identifying Problem Areas

Kanban tools also highlight potential issues that may be slowing production or increasing costs. For example, imbalances in workload distribution can be addressed by reallocating tasks among team members to improve efficiency.

3) Improving Communication

Kanban Boards facilitate clear communication across teams, even when using other methods like Agile Scrum or Extreme Programming (XP). They present information visually, making it accessible and understandable to everyone involved.

4) Flexibility

Kanban’s flexibility allows work to start based on client demand without fixed phase durations or deadlines. Teams can continuously reassess and adjust priorities using a feedback loop, adapting to new information as it arises.

5) Optimised Product Development

By breaking projects into smaller phases, Lean Kanban shortens the planning cycle and improves focus on immediate tasks, leading to more efficient product development.

6) Focus on Continuous Delivery

Lean Kanban promotes ongoing delivery by segmenting projects into manageable parts. This approach allows teams to adapt to changing client needs and maintain high delivery quality.

7) Reduction of Wasted Work / Wasted Time

The emphasis on continuous delivery and improvement reduces time spent on less valuable tasks. It minimises duplication of effort and focuses on activities that add the most value.

8) Better Predictability

Using relevant flow metrics, teams can better predict delivery dates based on past performance, enhancing their ability to forecast project timelines accurately.

9) Fewer Risks

Shorter feedback loops and a phased approach to project development mitigate risks. Smaller, incremental tasks mean that delays in one area have less impact on the overall project, making them easier to manage.

The transition from email to Kanban Boards streamlines Project Management. It exemplifies how managing tasks visually can eliminate the need for extensive email communication.

Lean Kanban: Driving Improvement and Respect for People

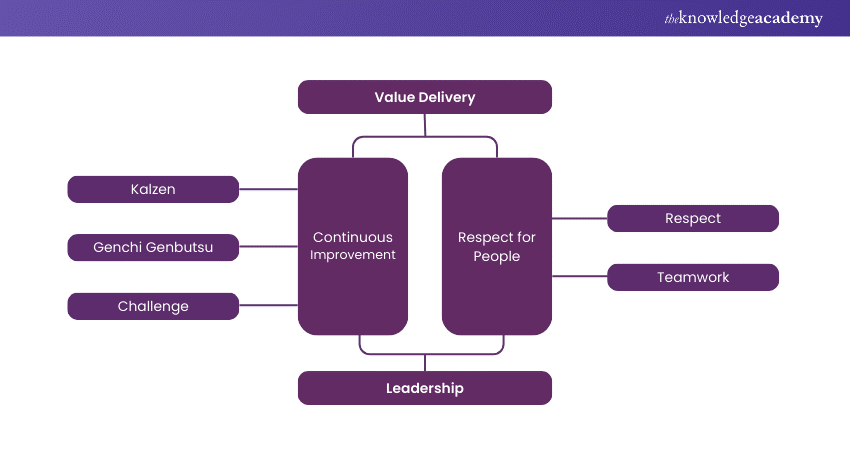

Lean Kanban fosters continuous improvement and respects people by integrating core principles from Lean methodology and Kanban systems.

Continuous Improvement: Lean Kanban promotes ongoing refinement of processes through its visual management approach. By mapping out workflows on a Kanban board, teams can clearly see and analyse each step of their processes. This visibility helps them identify bottlenecks, inefficiencies, and areas for enhancement.

Teams regularly review and adjust their workflows based on real-time data and feedback, fostering a culture of incremental improvement. This iterative process encourages teams to continually seek out better ways to perform tasks, reduce waste, and enhance overall productivity.

Respect for People: Lean Kanban places a strong emphasis on valuing and empowering team members. By providing transparency and involving everyone in the continuous improvement process, it respects the knowledge and insights of all team members.

Kanban Metrics play a vital role in Kanban Boards by facilitating open communication and collaboration, enabling teams to address issues collectively and make informed decisions. This inclusive approach not only respects individual contributions but also fosters a collaborative environment where team members are motivated to take ownership of their work and contribute to the team’s success.

Together, these principles ensure that Lean Kanban is not just about process optimisation but also about creating a supportive and engaged team dynamic, leading to better outcomes and a more respectful work environment.

Kickstart your Lean Management journey with our Certified Lean Foundation Course - Sign up today!

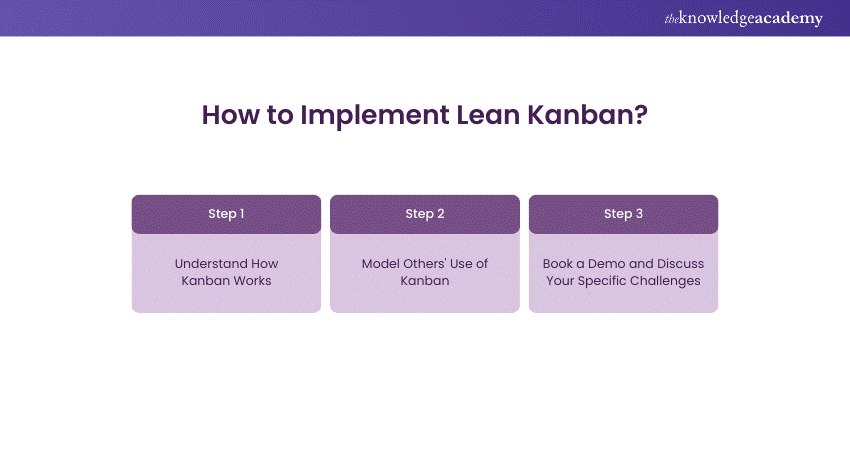

How to Implement Lean Kanban in Three Easy Steps?

Implementing Lean Kanban can streamline your Project Management and drive continuous improvement. By following these three simple steps, you can effectively integrate Lean Kanban into your workflow and enhance efficiency.

Step 1: Understand How Kanban Works

Start by familiarising yourself with the Principles of Kanban. Learn how it visualises workflows, manages task flow, and identifies bottlenecks. Understanding these fundamentals will provide a solid foundation for effectively applying Lean Kanban in your projects.

Step 2: Model Others' Use of Kanban

Observe and analyse how other teams or organisations successfully implement Kanban. Studying their practices and adaptations can offer valuable insights and help you adapt the methodology to fit your own team's needs.

Step 3: Book a Demo and Discuss Your Specific Challenges

Schedule a demonstration with a Kanban expert to see the system in action. Use this opportunity to discuss your unique challenges and get tailored advice on how to implement Lean Kanban effectively within your organisation.

Enhance your Business Improvement skills with our Lean Training- Register today!

Conclusion

Lean Kanban enhances Project Management by visualising workflows, fostering continuous improvement, and valuing team contributions. Its approach helps teams streamline processes, identify inefficiencies, and adapt swiftly to changes. By implementing Lean Kanban, you can boost productivity and achieve higher-quality outcomes, making it a valuable tool for modern Project Management.

Become a master of Lean Management with our Certified Lean Practitioner Course- Register now!

Frequently Asked Questions

What is the Difference Between Kanban and Lean Kanban?

Kanban is a visual tool for managing work, focusing on workflow visualisation and task management. Lean Kanban combines Kanban with Lean principles, incorporating continuous improvement and waste reduction to optimise efficiency and value delivery beyond basic Kanban practices.

How do Lean and Kanban Work Together?

Lean and Kanban work together by integrating Lean’s focus on eliminating waste and improving processes with Kanban’s visual workflow management. This combination enhances efficiency, fosters continuous improvement, and ensures work is managed effectively, driving overall productivity.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are the Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various Lean Training, including the Introduction to Lean, Certified Lean Foundation, and Certified Lean Practitioner. These courses cater to different skill levels and provide comprehensive insights into Lean Principles.

Our Business Improvement Blogs cover a range of topics related to Lean Management, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Lean Management skills. The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Introduction to Lean

Introduction to Lean

Fri 16th May 2025

Fri 5th Sep 2025

Fri 5th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please