We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Production planning is a vital component of manufacturing and business operations, ensuring the seamless flow of processes from raw material acquisition to the final product delivery. It involves strategising and organising resources—like workforce, equipment, and materials—to optimise efficiency, reduce downtime, and meet customer demands within a set timeframe. This essential process not only aligns production with market demands but also mitigates risks associated with underproduction, delays, or wastage.

In today’s ever-changing business environment, production planning plays a pivotal role in maintaining a competitive edge. Whether it’s forecasting demand, scheduling production timelines, or managing inventory levels, a robust production plan helps businesses achieve operational efficiency.

Table of Contents

1) What is Production Planning?

2) Why is Production Planning Important?

3) History of Production Planning

4) Types of Production Planning

5) Production Planning Process

6) How to Make a Production Plan?

7) Production Planning Strategies

8) Conclusion

What is Production Planning?

Production Planning is about laying out a simple and intelligent plan for making a company's products or services. It used to be something only big manufacturers focused on, but thanks to new tech, even small and mid-sized businesses, no matter the industry, can now take advantage of it.

This comprehensive process involves several key elements, starting with demand forecasting, which predicts future customer needs using various Methods of Demand Forecasting. It also entails identifying the raw materials required for production, assessing the workforce for manufacturing tasks, and determining the appropriate equipment and technology.

Why is Production Planning Important?

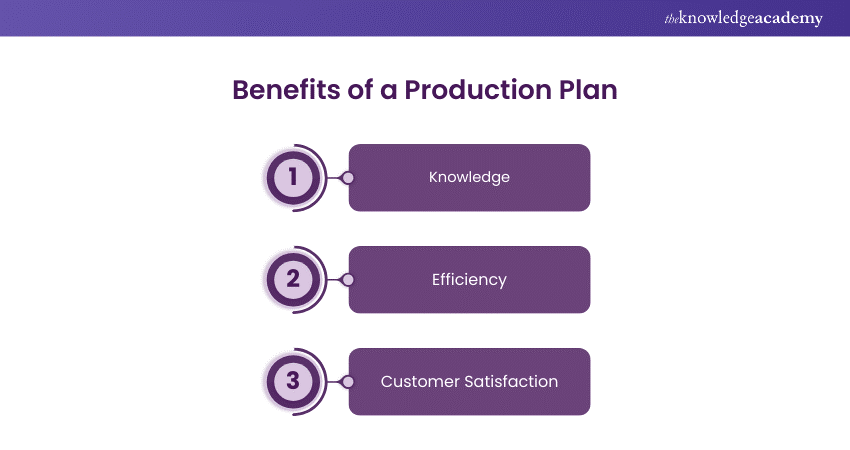

An effective production plan can drive increased revenue, higher profits, and greater customer satisfaction, while a poorly executed one can create production issues and potentially jeopardise the entire business. Key benefits of a well-developed production plan include:

a) Knowledge: It offers a clear roadmap for understanding the resources and production steps necessary to meet customer demands. It also helps identify potential production challenges and strategies for managing them.

b) Efficiency: Comprehensive Production Planning reduces bottlenecks, minimises costs, and maintains product quality while keeping expenses aligned with the budget.

c) Customer Satisfaction: By assuring timely production and delivery, a solid production plan boosts customer satisfaction and encourages repeat business.

History of Production Planning

Production Planning began in the early 19th century to manage large-scale operations in industries like railroads and factories. Initially simple, with foremen handling basic schedules for limited products, it evolved as manufacturing grew more complex. By the early 20th century, Production Planning focused on optimising processes and reducing costs.

Today, it has transformed with technological advancements, enabling real-time communication, precise forecasting, and resource allocation. Modern Production Planning now emphasises efficiency, waste reduction, and adapting to changing products and customer expectations, making it crucial for industries of all sizes.

Enhance your skills and elevate your career—join our Facilities Management Training today!

Types of Production Planning

Production Planning includes various strategies, each focusing on different aspects of the process. Key types include:

a) Master Production Schedule (MPS): These are detailed schedules for producing specific commodities within a set timeframe, often generated by software and fine-tuned by users.

b) Material Requirements Planning (MRP): This system manages production, scheduling, and inventory control, ensuring raw materials are available, minimising stock levels, and organising manufacturing and purchasing activities. It is often automated but can be done manually.

c) Capacity Planning: This assesses whether an organisation has the capacity to meet changing demands.

d) Workflow Planning: This outlines the sequence of tasks for employees or teams, optimising operational efficiency.

Production Planning principles are also applied in other areas, such as:

a) Enterprise Resource Planning (ERP): Integration of key business processes into a unified system, often software-based.

b) Sales and Operations Planning (S&OP): Aligning production supply with existing demand for better accuracy.

Production Planning Process

The Production Planning process consists of the following steps:

a) Estimate Product Demand: This step involves outlining the quantity of products needed within a specific period, using historical production data and analysing emerging market trends.

b) Evaluate Production Options: Companies assess available resources and explore ways to maximise their use based on demand estimates.

c) Select the Most Efficient Option: The approach should optimise resource use, minimising costs and production time.

d) Monitor and Evaluate: As the plan is implemented, companies track progress against the plan and assess any discrepancies.

e) Adjust the Plan: Based on evaluations, companies may modify the plan to improve efficiency and meet customer demands in future production cycles.

Take control of your production success by mastering the Objectives of Production Management. Start now!

How to Make a Production Plan?

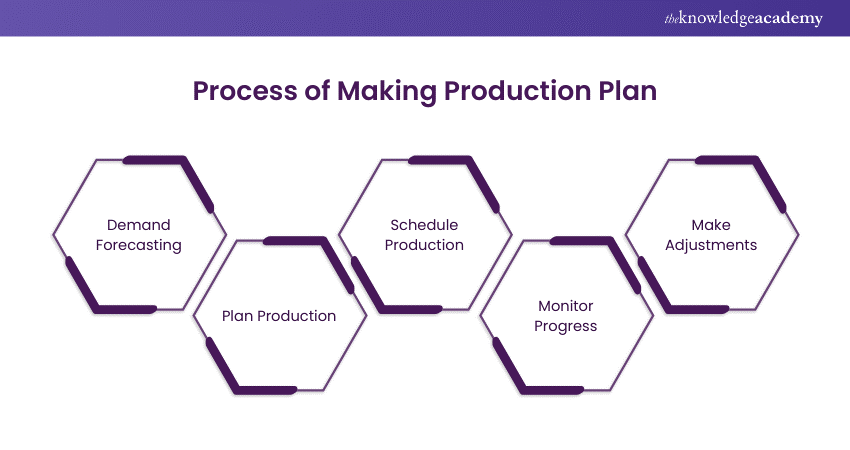

The Production Planning process encompasses the following steps:

Demand Forecasting

This creates an initial estimate of the number of products to be produced within a specific timeframe, combining analysis of past production trends with emerging market trends.

Plan Production

This step involves assessing available resources and determining the most effective way to utilise them based on projected demand estimates.

Schedule Production

Companies should prioritise resource use that minimises costs while maximising time efficiency.

Monitor Progress

As the plan unfolds, companies track actual progress against the expected outcomes and evaluate any discrepancies.

Make Adjustments

Companies may need to adjust the plan to meet customer goals better and improve the efficiency and success of future production efforts.

Production Planning Strategies

Effective Production Planning is crucial for efficient resource use, cost control, and timely product delivery. Here’s a look at five key production strategies:

Stock Production

Also known as make-to-stock (MTS), this strategy involves manufacturing products in advance based on demand forecasts. It ensures quick customer order fulfilment but requires accurate demand prediction to avoid overproduction or stockouts.

Best for: Predictable demand, reduced lead times, and long shelf-life products.

Custom Orders

Make-to-order (MTO) focuses on producing goods based on specific customer orders. It allows for complete customisation but usually results in longer delivery times.

Best for: Low-demand speciality items where personalisation is key.

Assemble Orders

Assemble-to-order (ATO) involves building components in advance, with final assembly done after receiving customer orders. It balances speed and customisation.

Best for: Multiple product variants, faster delivery, and industries like electronics or automotive.

Demand Matching

Also known as just-in-time (JIT), this strategy aligns production with actual demand to minimise inventory costs and waste. It requires strong coordination between production and sales teams.

Best for: Volatile demand, lean operations, and rapidly changing products.

Steady Production

Level production maintains a consistent output regardless of demand shifts. It optimises resource use but may lead to higher inventory during slow periods.

Best for: Stable demand, long shelf-life products, and industries with high fixed costs.

Discover the art of floral design and unleash your creativity—join our Floristry Introduction Course!

Conclusion

Production Planning isn’t just a behind-the-scenes process; it’s the backbone of manufacturing success. It transforms chaos into consistency by aligning resources, optimising workflows, and meeting demand with precision. The Functions of Production Management play a key role in this process, ensuring that every aspect of production runs smoothly. Whether fine-tuning stock levels or customising orders, mastering Production Planning, backed by these functions, is your ticket to efficiency, profitability, and happy customers.

Master the craft of coffee-making and start your journey as a barista—Join our Basic Barista Course today!

Frequently Asked Questions

What is the Main Purpose of Production Planning?

The primary purpose of Production Planning is to efficiently manage resources, optimise workflows, and ensure timely product delivery, all while minimising costs and meeting customer demand.

What are the Key Factors in Production Planning?

Key factors include demand forecasting, resource availability, production capacity, scheduling, cost management, and quality control to ensure smooth and efficient production processes.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various Industry Training, including Product Management Training, Facilities Management Training and Supply Chain Management Training. These courses cater to different skill levels, providing comprehensive insights into Facility Management

Our Business Skills Blogs cover a range of topics related to Product Management, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Product Management skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Skills Resources Batches & Dates

Date

Product Management Training

Product Management Training

Fri 25th Apr 2025

Fri 20th Jun 2025

Fri 29th Aug 2025

Fri 31st Oct 2025

Fri 19th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please