We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Teams in sync, deadlines met with ease, and delighted customers - This is the dream scenario for any business. The proven way to accomplish this is through Capacity Requirement Planning (CRP), a process that helps companies align their production capacity with fluctuating demand. Understanding What is Capacity Requirement Planning is akin to solving a puzzle where every piece represents time, resources, and market demand. It's all about making sure the pieces fit. This blog explores the art of CRP, guiding you on balancing resources, predicting demand, and keeping your business running without stumbling. So read on, master perfection in production and stay competitive!

Table of Contents

1) What is Capacity Requirement Planning?

2) Importance of Capacity Requirement Planning

3) Factors Affecting Capacity Requirements Planning

4) Types of Capacity Requirement Planning

5) Benefits of Capacity Requirement Planning

6) How to Plan Capacity Requirements Planning?

7) Strategies for Capacity Requirement Planning

8) Conclusion

What is Capacity Requirements Planning?

Capacity Requirements Planning (CRP) determines whether a company’s available production capacity can meet its goals. CRP first examines the company’s planned manufacturing schedule and then weighs it against the company’s production capabilities to confirm if meeting the capacity is realistic.

If the production capacity is found to be inadequate, the company may alter its production goals or take different steps to bring production capabilities in line with capacity. CRP goes hand in hand with manufacturing requirement planning, which ensures an organisation has the physical assets to meet production needs.

Importance of Capacity Requirement Planning

Capacity Requirement Planning (CRP) is important for several reasons:

1) It provides a clear picture of a company's ability to meet customer demand.

2) It helps determine how much that company must invest in its equipment, employees, and materials.

3) It helps to find the company’s place in the market.

4) It minimises excess capacity and waste.

5) It improves overall efficiency and competitiveness.

6) It allows for flexibility to help create a wide range of products.

Factors Affecting Capacity Requirements Planning

There are various factors that impact Capacity Requirements Planning. These include product types, finances, skilled workforce and equipment capacity. Let’s explore these factors:

1) Product Types

Complex products require more time to produce, lead to production delays, and need more skilled employees and the most efficient equipment. On the other hand, simple products need less time and can be produced in large quantities within a short period.

2) Finances

A business must have sufficient financial resources to invest in new machinery, expand operations, or hire additional employees. This determines sustainable growth and productivity and enables the organisation to seize opportunities in a competitive market environment.

3) Skilled Workforce

A company relying on unskilled or equally qualified employees without improving their skills or hiring more skilled staff can negatively impact production capacity. A lack of skilled workers or an inability to recruit additional talent can restrict output levels.

4) Equipment Capacity

Maintaining equipment in good condition is vital for an efficient production process. Well-functioning machinery reduces downtime, minimises maintenance delays, and confirms consistent output quality. In Capacity Requirement Planning, reliable equipment is vital for meeting production demands and achieving operational efficiency.

Types of Capacity Requirement Planning

There are three main types of Capacity Requirement Planning. Together, they can ensure you have an adequate amount of each for both the short and long-term. They are explored below:

1) Workforce Capacity Planning

This strategy enables you to ensure adequate human resources to fulfil consumer demand. You need the correct number of people and the right skills so that the tasks are completed efficiently. If you need to hire more people or fire some, you'll know how soon you have to make changes to account for the time taken for the recruitment and onboarding process.

2) Product Capacity Planning

This type of CRP helps you determine if your business has an adequate quantity of products or resources needed to fulfil deliverables. For instance, if it’s a baby needs store, you need to check stocks of baby clothes, lotions, booties, diapers, baby foods, feeding bottles, toys, cradles, cribs, and so on. These are the things required to fulfil customer demand.

3) Tool Capacity Planning

As the name suggests, this strategy ensures you have the requisite tools, like vehicles, computers, forklifts, etc., required to produce and deliver your goods and services without any delay.

Learn how to implement inventory planning for an efficient Supply Chain in our Supply Chain Management Training - Sign up now!

Benefits of Capacity Requirement Planning

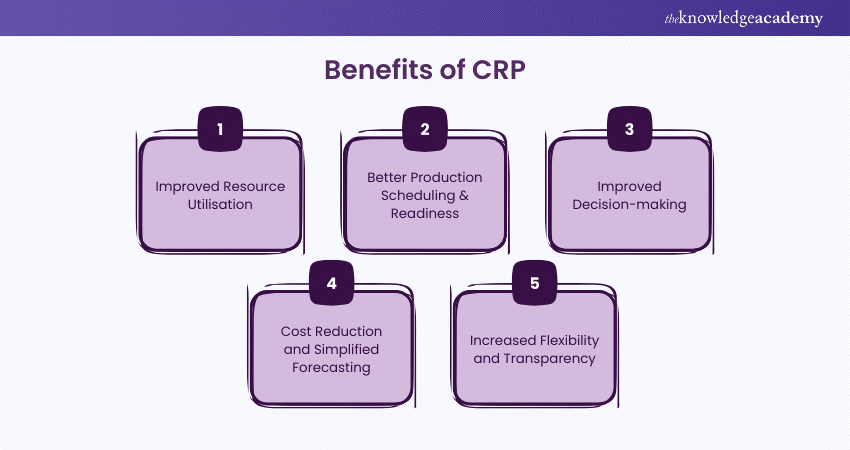

Capacity Requirement Planning brings plenty of benefits on the table. As we’ve previously explored, CRP leads to improved Cost Management and efficiency. Let’s look at its key advantages for organisations

1) Scenario Readiness

A well-prepared capacity planning helps the business stay prepared for numerous scenarios. It'll remove a lot of pressure, and if you know the steps to be taken for each type of capacity, it'll be easier to meet demand in any period.

2) Team Optimisation

Efficient CRP involves matching the existing team's availability and skill sets with the requirements of upcoming projects. So, if there are insufficient resources for a project, you'll gain insight into how to add more resources to your team. As a business owner, it's crucial to understand the team’s skill sets, and consequently, CRP has the potential to speed up staffing decisions and mitigate the risk of burnout.

3) Cost Efficient

Effectively managing a team’s capacity involves maximising your resources to align with the scope of work that needs to be done. So, you don’t have to pay for more resources than you require, eventually reducing production costs.

Let's say there are 13 team members assigned to Project A, which requires only nine; you can reassign three of those team members to Project B. Such reallocation helps reduce expenses pertaining to Project A.

4) Simplified Forecasting

Capacity Requirement Planning is beneficial for understanding the capacity requirements for current planning as well as future scope. So, the same plan can be used for future projects if capacity planning is created for the current project. The template will serve as a valuable initial reference point, eliminating the need for predicting capacity needs from the beginning. This can save time and accelerate the capacity planning procedure.

5) Enhanced Transparency

With CRP, more inefficiencies can be highlighted which can be further optimised. Stakeholders can leverage this data to gain a clear view and determine how they can invest their money and resources.

Learn to analyse complex situations and make informed choices in our comprehensive Management Training – Sign up now!

How to Plan Capacity Requirements Planning?

An important point to note is that CRP depends on the accuracy of the data used for the process. If the company still relies on old spreadsheets or other disparate systems, the information it gathers may not be accurate or updated. So, the company must look for modern ways such as automated software for accurate, relevant, and updated information. When planning capacity requirements, the following steps are essential:

Step: 1. Evaluate Current Capacity

In this step, information regarding time studies and live data on equipment capabilities must be collected. Various other elements must be analysed, such as absenteeism, the number of hours and available shifts, and supply chain variables, including vendor performance, lead times, and inventory data.

Step: 2. Create Demand Forecast

The development of a demand plan is critical for capacity planning. Supply Chain Management software can help acquire accurate data as it'll allow aggregate demand planning, based on production time, to do the following:

a) Calculate work centre capacity.

b) Find out bottlenecks in advance.

c) Analyse the what-if scenarios.

d) Master scheduling.

Step: 3. Plan Capacity Adjustments

The first two steps provide a clear understanding of capacity and demand. This step allows you to adjust for determining demand. Consider the following points:

a) Decide if overtime or additional shifts are needed.

b) Analyse if certain production aspects need to be outsourced.

c) If you find the demand to be consistent, consider buying additional equipment.

Strategies for Capacity Requirement Planning

Now that we have explored how to plan Capacity Requirement Planning, let’s look at some proven strategies to make your capacity planning a success.

1) Lag Strategy

This involves maintaining sufficient resources to fulfil current demand (disregarding projected demand estimates). The lag strategy is ideal for smaller organisations with low-capacity requirements.

2) Lead Strategy

This strategy ensures that the business has adequate resources to meet demand planning forecasts. A lead strategy is useful when there's excess demand, as the extra capacity will help meet that demand.

3) Match Strategy

This strategy is a blend of lag and lead strategy. In this situation, Project Managers must monitor the market trends, actual demand and demand forecasts to adjust the capacity requirements accordingly.

4) Dynamic Strategy

In this strategy, the manufacturer analyses the actual demand and sales forecast, and then he adds the capacity requirements. Dynamic strategy is safe, accurate and less risky.

Conclusion

In conclusion, Capacity Requirement Planning (CRP) is the backbone of efficient operations as it ensures resources align with demand for seamless performance. By understanding What is Capacity Requirement Planning, and its principles, you can reduce bottlenecks, optimise workflows, and boost productivity for your business. So mastering CRP is the key to creating a resilient system ready to meet any market challenge.

Learn how to create internal controls, tools, and metrics in our detailed Business Process Improvement Course – Register now and elevate your business!

Frequently Asked Questions

Capacity Requirement Planning (CRP) aims to align an organisation's capacity with its demand to optimise efficiency and maintain customer satisfaction.

The three key inputs to capacity planning are demand forecasting, resource availability, and operational constraints. Demand forecasting helps evaluate future needs, resource availability assesses current needs, and operational constraints determine system limitations.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Management Courses, including the Introduction to Supplier Management Course and the Category Management Fundamentals Course. These courses cater to different skill levels, providing comprehensive insights into Quality Assurance Plan.

Our Business Skills Blogs cover a range of topics related to Capacity Requirement Planning, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Business Skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Skills Resources Batches & Dates

Date

Business Process Improvement Training

Business Process Improvement Training

Fri 28th Feb 2025

Fri 4th Apr 2025

Fri 27th Jun 2025

Fri 29th Aug 2025

Fri 24th Oct 2025

Fri 5th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please