We may not have the course you’re looking for. If you enquire or give us a call on +1800812339 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

ISO 13485 strictly regulates medical devices and ensures their highest quality to reduce the risk of failures. There are several Benefits of ISO 13485 that you can enjoy as a manufacturer or an organisation dealing with medical equipment. It helps you establish a Quality Management System (QMS) that focuses on Risk Management, effective documentation and more. In this blog, you will learn the key Benefits of ISO 13485 with examples that might help you.

Table of Contents

1) What is ISO 13485?

2) Benefits of ISO 13485

a) Enhanced Product Quality

b) Regulatory Compliance

c) Improved Customer Confidence and Trust

d) Efficient Processes, Documentation and Streamlined Operations

e) Improved Risk Management

f) Access to a Wider and Global Market

g) Fosters the Culture of Continuous Improvement (CI)

h) Better Supplier Relationship Manager

i) Efficient Post-market Survey

j) Competitive Advantage and Business Growth

3) Conclusion

What is ISO 13485?

ISO 13485 is an internationally recognised quality management system standard tailored to the medical device industry. It establishes the requirements for organisations to implement and maintain an effective QMS focused on medical devices. By emphasising risk management and regulatory compliance, ISO 13485 ensures the production of safe and high-quality medical devices. Successful ISO 13485 implementation lies in a thorough understanding and application of the ISO 13485 Principles, which provide a framework for building and maintaining a robust and effective Quality Management System. Certification to this standard demonstrates a commitment to quality and instils confidence in customers, stakeholders, regulatory bodies, and those seeking ISO 13485 Auditor Jobs.

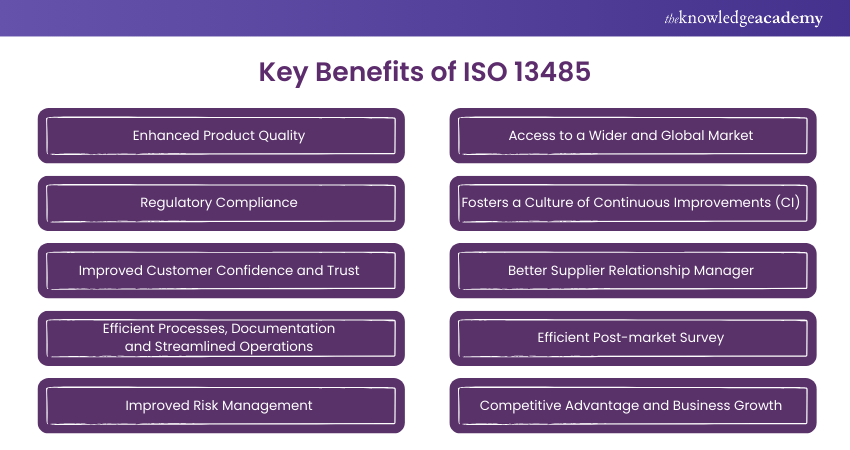

Benefits of ISO 13485

ISO 13485 is a valuable tool for organisations in the medical device industry, offering numerous benefits that positively impact product quality, regulatory compliance, customer satisfaction, and overall business performance, which in turn can influence the ISO 13485 Auditor Salary due to the high demand for skilled auditors. Let's explore the top benefits of implementing ISO 13485.

Enhanced Product Quality

ISO 13485 strongly emphasises risk management and quality control throughout the product lifecycle. By implementing this standard, organisations establish robust processes that ensure consistent product quality, reducing the risk of defects and improving patient safety.

Example: Consider a scenario where a medical device manufacturer adheres to ISO 13485. As part of their quality management system, they conduct thorough risk assessments during a new medical device's design and development stage. This involves identifying potential hazards, such as design flaws or material incompatibilities, and evaluating the severity of their impact.

Regulatory Compliance

ISO 13485 aligns with global regulatory requirements for medical devices. Implementing these standards aids organisations in meeting regulatory obligations, streamlining audits, and facilitating market access.

Example: A medical device company that obtains ISO 13485 Certification is better positioned to navigate regulatory hurdles when seeking approval for new product launches. The certification demonstrates compliance with applicable regulations and increases the likelihood of successful regulatory audits.

Gain a competitive edge with ISO 13485 Training – Start your path to quality excellence now!

Improved Customer Confidence and Trust

ISO 13485 Certification is a mark of quality and reliability. Customers, healthcare professionals, and regulatory bodies place trust in organisations that adhere to this standard, promoting confidence in the safety of their products.

Example: A medical device supplier with ISO 13485 certification has a competitive edge in the market. Customers are more likely to choose their products over those from non-certified competitors, knowing that the devices have undergone rigorous quality control processes.

Efficient Processes, Documentation and Streamlined Operations

ISO 13485 promotes efficient processes, ensuring smooth operations throughout the organisation. Organisations can eliminate redundancies, reduce errors, and optimise resource allocation by standardising these procedures.

Example: An organisation following ISO 13485 guidelines implements standardised work instructions and streamlined production processes. This results in improved efficiency, reduced waste, and shorter lead times, ultimately enhancing customer satisfaction.

The ISO 13485 standard's focus on documentation, traceability, and risk management ensures that the necessary processes and controls are in place to meet regulatory requirements. By maintaining compliance with the standard, organisations can more effectively navigate inspections and audits from regulatory bodies.

Improved Risk Management

ISO 13485 Certification is a powerful tool to instil confidence in customers, healthcare professionals, and regulatory bodies. By adhering to this standard, organisations demonstrate their commitment to delivering safe and effective medical devices, leading to increased customer confidence.

Example: A medical device supplier with ISO 13485 certification gains a significant competitive advantage in the market. Customers and healthcare professionals often prioritise products that meet recognised quality standards. When a customer sees that a supplier holds ISO 13485 Certification, it assures that the supplier has implemented a robust quality management system specifically tailored for medical devices.

Access to a Wider and Global Market

ISO 13485 Certification opens doors to international markets. Many countries and regulatory bodies recognise this standard as a prerequisite for market entry, enabling organisations to expand their reach and access new business opportunities.

Example: A medical device company earns the ISO 13485 Certification and enters international markets. This certification proves compliance with quality standards, simplifying entering and operating in new geographical areas.

Learn about the best practices for implementing ISO 13485 standards with our ISO 13485 Lead Implementer Training – Join today!

Fosters a Culture of Continuous Improvements (CI)

ISO 13485 fosters a culture of Continuous Improvement within organisations. By establishing metrics, conducting regular audits, and implementing corrective actions, organisations can drive ongoing enhancements to their quality management system.

Example: An organisation certified to ISO 13485 will conduct regular internal audits to identify areas for improvement. Through data analysis and process optimisation, they make informed decisions that enhance product quality and increase customer satisfaction.

By identifying and eliminating non-value-added activities and bottlenecks, improving workflow, and enhancing communication channels within the organisation, the manufacturing process can be optimised to minimise the potential for human errors and reduce the need for rework.

Better Supplier Relationship Manager

ISO 13485 emphasises the importance of supplier evaluation and control. By implementing stringent supplier management processes, organisations can ensure the quality and reliability of external parties' raw materials, components, and services.

Example: An organisation following ISO 13485 guidelines maintains a robust supplier evaluation system, conducting regular assessments and audits. This ensures suppliers meet the necessary quality requirements, reducing the risk of receiving substandard materials or services.

Efficient Post-market Survey

ISO 13485 mandates effective post-market surveillance processes. Organisations must monitor and analyse feedback, complaints, and adverse events related to their products, enabling them to take swift corrective actions and improve product safety.

Example: A medical device manufacturer with ISO 13485 certification establishes a systematic post-market surveillance system. By analysing customer complaints and adverse event reports, they identify trends and implement product improvements to enhance patient safety.

Competitive Advantage and Business Growth

ISO 13485 Certification provides organisations with a competitive edge in the medical device industry. It enhances brand reputation, increases market share, and opens up opportunities for collaborations and partnerships, driving overall business growth.

Example: A medical device company with ISO 13485 certification becomes a preferred partner for hospitals and healthcare providers. The certification is a testament to their commitment to quality, making them an attractive choice for potential collaborations and contracts.

Learn quality auditing with our ISO 13485 Internal Auditor Course – Join today!

Conclusion

The Benefits of ISO 13485 are plenty for organisations operating in the medical device industry. From enhancing product quality and ensuring regulatory compliance to fostering customer confidence and driving business growth, this internationally recognised standard plays a pivotal role in maintaining high standards of quality and safety. By implementing ISO 13485, organisations can establish a solid foundation for success, positioning themselves as leaders in the medical device market.

Learn about the implementation stages of ISO frameworks with our ISO 13485 Foundation Training – Join today!

Frequently Asked Questions

How Does ISO 13485 Help with Risk Management in Making Medical Devices?

ISO 13485 sets rules to identify and reduce risks in making medical devices. It ensures that every step, from design to delivery, follows strict safety standards. This reduces the chances of errors and makes the devices safer for users.

How Does ISO 13485 Certification Make Customers Happier?

ISO 13485 shows that a company meets high-quality standards in making medical devices. It builds trust with customers, as they know the products are safe and reliable. This leads to more satisfied and loyal customers.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 3,000 online courses across 490+ locations in 190+ countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various ISO 13485 Training, including the ISO 13485 Foundation Course, ISO 13485 Lead Auditor Course, and ISO 13485 Lead Implementer Course. These courses cater to different skill levels, providing comprehensive insights into Information Security Risk Management.

Our Health & Safety Blogs cover a range of topics related to ISO 13485, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your compliance knowledge, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

ISO 13485 Foundation

ISO 13485 Foundation

Mon 3rd Mar 2025

Mon 5th May 2025

Mon 7th Jul 2025

Mon 8th Sep 2025

Mon 3rd Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please