We may not have the course you’re looking for. If you enquire or give us a call on +41 315281584 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

So, What is Logistics? It can be defined as the movement of items, services, and information from origin to state of use in the Supply Chain vs Logistics process. It plays a crucial role in Supply Chain Management and is essential for businesses to meet customer demands while minimising operational expenses.

Efficient logistics relies on optimising routes, maintaining appropriate inventory levels, and utilising technology and automation. It also involves compliance with regulations, risk management, cost control, and a strong focus on customer service. In this blog, we will elaborate on "What is Logistics?" and how it significantly influences a product's journey from production to the end consumer.

Table of Contents

1) What is Logistics?

2) The Core Components of Logistics

3) The Importance of Logistics in Modern Business

4) Challenges in Logistics

5) Role of Logistics in Business Operations

6) What is Logistics Management?

7) Difference Between Logistics and Supply Chain Management

8) What is the Main Focus of Logistics?

9) What are the 7 Cs of Logistics?

10) Conclusion

What is Logistics?

Logistics is all about the efficient movement of goods, resources, and information from one point to another. It involves everything from sourcing materials and storing inventory to ensuring timely transportation to the destination.

Businesses rely on logistics management to streamline operations, reduce costs, and improve efficiency. A logistics manager, often called a logistician, plays a crucial role in coordinating these processes.

Originally, logistics was a military term used to describe how armies managed supplies, equipment, and troop movements. Over time, its meaning has expanded, and today, it is a key function in industries like manufacturing, retail, and e-commerce. Whether it's getting raw materials to a factory or delivering a package to your doorstep, logistics keeps the world running smoothly.

The Core Components of Logistics

Understanding Logistics requires delving into its primary pillars. Here's a deeper look into each component:

1) Transportation

a) Mode Selection: Choosing between road, sea, air, or rail impacts cost, speed, and environmental footprint.

b) Route Planning: Efficient paths reduce fuel costs, delivery times, and environmental impacts.

c) Timeliness: Ensuring goods arrive when expected builds consumer trust and reduces storage costs.

d) Cost Efficiency: Optimal transportation choices and negotiations reduce shipping expenses, benefiting both businesses and consumers.

Keen on getting a deeper knowledge on Supply Chain Management, refer to our blog on Objectives of Supply Chain Management.

2) Warehousing and Storage

a) Strategic Locations: Placing warehouses in key areas minimises transportation costs and time.

b) Safety Measures: Proper security protocols prevent theft or damage to stored goods.

c) Organisation Systems: Effective layout and indexing ensure quick retrievals and reduce handling errors.

d) Climate Control: Some goods, like perishables, require specific temperatures or humidity levels for preservation.

Inventory Management

a) Demand Forecasting: Predictive tools help gauge future product demands, aiding stock decisions.

b) Stock Levels: Maintaining optimal stock prevents overstock costs and product shortages.

c) Replenishment Systems: Automated processes ensure stock is reordered at the right time, maintaining a flow.

d) Waste Reduction: Efficient inventory management minimises expired or obsolete items, reducing losses.

Information Management

a) Real-time Tracking: Modern tools offer real-time insights into shipments, enhancing transparency for consumers.

b) Data Analytics: Analysing Logistics data can spotlight inefficiencies and suggest optimisation strategies.

c) Integrated Systems: Connecting all Logistics components digitally ensures synchronised operations digitally.

d) Decision Support: Accurate, timely data empowers businesses to make informed logistical choices, boosting efficiency and customer satisfaction.

Navigate your way to success with these comprehensive Logistics Interview Questions!

The Importance of Logistics in Modern Business

Logistics serves as the intricate thread weaving together various elements. This sector doesn't just move goods; it facilitates connections, drives efficiency, and shapes customer experiences. Here's an expanded view of its indispensable role:

Global Reach

a) Connecting Markets: In an interconnected world, Logistics forms bridges, enabling businesses to tap into distant markets and diversify their consumer base.

b) Cultural Understanding: Different regions have unique regulations and preferences. Logistics helps businesses tailor their approach, respecting local nuances.

c) Supply Chain Flexibility: The unpredictable nature of global events requires an agile Supply Chain. Logistics provides the adaptability to manoeuvre through challenges and maintain business flow.

Customer Satisfaction

a) Timely Deliveries: Delivering on promises is crucial. When Logistics ensures punctual deliveries, it solidifies consumer trust.

b) Product Availability: A seamless shopping experience relies on product availability. Logistics manages inventory to prevent disappointing stockouts.

c) Returns and Exchanges: A hassle-free return process can make or break customer loyalty. Efficient Reverse Logistics makes this possible.

Operational Efficiency

a) Cost Management: By optimising routes, storage, and transport modes, Logistics plays a pivotal role in cost-saving.

b) Resource Utilisation: Maximising the use of assets, from trucks to warehouse space, ensures higher productivity and fewer overheads.

c) Data-driven Decisions: Logistics offers a treasure trove of data. Analysing this can spotlight areas for improvement and streamline operations.

Sustainability and Ethics

a) Eco-friendly Operations: Conscious consumers demand sustainability. Logistics responds with green transport modes and packaging solutions.

b) Ethical Sourcing: Ethical Logistics ensures products are sourced responsibly, supporting fair labour practices and sustainable methods.

c) Waste Reduction: Reducing product waste isn't just eco-friendly, it's also cost-effective. Logistics aids in this mission with efficient inventory management.

Technology Integration

a) Automation: From robot-assisted warehousing to automated delivery schedules, Logistics harnesses technology for increased efficiency.

b) Digital Tracking: Real-time tracking tools empower consumers, offering them visibility into product journeys.

c) Predictive Analysis: Predicting market trends and demands helps businesses stay prepared. Logistics technology offers this foresight.

Streamline your operations with Industry Training! Optimise sourcing, transport & inventory for seamless business success - Get started today!

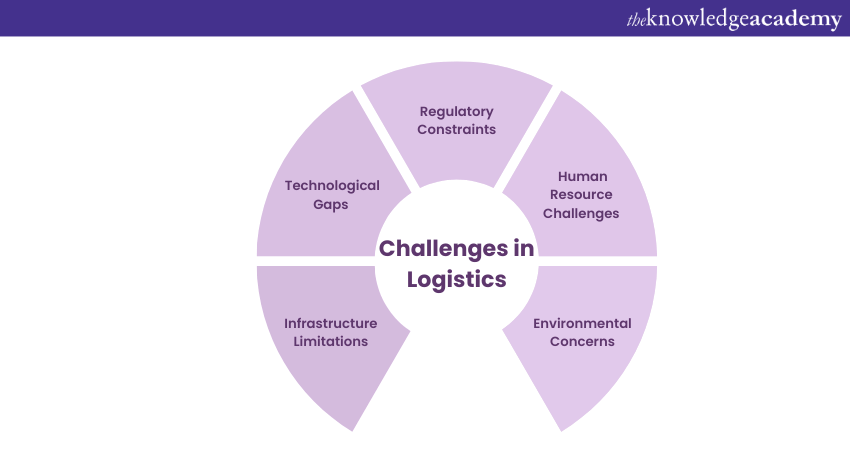

Challenges in Logistics

Logistics not only facilitates global commerce but also presents multiple challenges that require attention for seamless operations. Here's a more comprehensive dive into these challenges:

Infrastructure Limitations

a) Underdeveloped Regions: Some areas lack proper roads or transport networks, making delivery and procurement challenging.

b) Urban Congestion: Dense city traffic can escalate fuel consumption, extend delivery times, and amplify logistic costs.

c) Lack of Facilities: Limited or outdated storage and handling facilities can reduce the storage quality and increase spoilage or damage risks.

d) Transport Maintenance: Aging vehicles or transport modes can lead to frequent breakdowns and inefficiencies.

Technological Gaps

a) Outdated Systems: Relying on old systems might result in slow processes, missed opportunities, and poor data analysis.

b) Integration Issues: Blending old and new tech can lead to data discrepancies and system crashes.

c) Cybersecurity Threats: Without secure platforms, sensitive data can be at risk, potentially harming business reputation.

d) Tech Adoption Resistance: Employees accustomed to traditional methods may resist adopting modern solutions, slowing progress.

Regulatory Constraints

a) Customs and Duties: Each country has customs protocols, sometimes leading to unexpected fees or shipment delays.

b) Environmental Regulations: Meeting ever-changing eco-friendly standards may involve constant adaptation and financial outlays.

c) Local Laws: Compliance with diverse local Logistics-related laws can complicate cross-border operations.

d) Trade Tariffs: Unanticipated tariffs or trade wars can disrupt established Supply Chains.

Human Resource Challenges

a) Skill Gaps: As Logistics evolves, the need for upskilling becomes critical to meet industry demands.

b) Labour Shortages: Peak seasons or regional labour shortages can disrupt normal operations.

c) Safety Concerns: Ensuring staff welfare reduces turnover and accidents, especially in physically demanding roles.

d) Communication Barriers: Working globally might introduce language or cultural communication challenges.

Environmental Concerns

a) Carbon Footprint: Identifying and switching to low-emission transportation modes is crucial for sustainability.

b) Waste Management: Efficiently managing and reducing logistical waste, especially plastics, is essential for eco-friendliness.

c) Sustainable Sourcing: Finding suppliers prioritising eco-friendly practices while maintaining quality is challenging.

d) Energy Consumption: Warehouses and transport modes consume energy, emphasising the need for green energy solutions.

Mitigating these challenges not only streamlines Logistics but also bolsters business reputation, ensuring they remain competitive and responsive to global market demands.

Master the Supply Chain: Enrol in our Supply Chain Management Training today!

Role of Logistics in Business Operations

Logistics is essential for the seamless exchange of goods and services, ensuring businesses operate efficiently and profitably. It manages the flow of resources from suppliers to end-users, whether in bulk shipments to manufacturers or individual orders to customers. Without logistics, transactions stall, supply chains break down, and businesses lose revenue. Here are the seven key pillars of effective logistics:

1) Material Sourcing

Procuring materials goes beyond simply hunting for the cheapest options. Companies must assess vendor dependability, production timelines, hidden expenses (like tariffs or quality checks), and adherence to ethical or environmental standards. This ensures steady material flow while reducing vulnerabilities and interruptions.

2) Transportation

Choosing appropriate shipping methods—whether air freight, ground transport, or ocean cargo—requires balancing urgency, budget, and volume. Logistics professionals strategically plan delivery paths, manage relationships with various transport providers, and handle international documentation to meet deadlines and avoid bottlenecks.

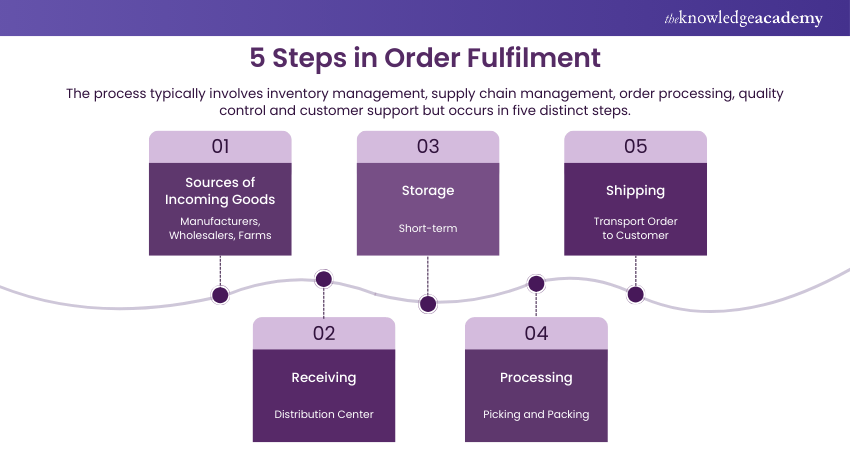

3) Order Fulfilment

This critical operation covers everything from retrieving items in a warehouse to securely packaging and dispatching them. Streamlined processes guarantee punctual shipments, which not only boost client trust but also reinforce a company’s credibility in competitive markets.

4) Warehousing

Effective warehousing focuses on intelligent space utilization rather than just stacking goods. Companies need to implement systems for specialized needs (like refrigeration or expedited loading zones), strategically position inventory for quick access, and maximize facility layouts to cut processing times and reduce errors.

5) Demand Forecasting

Precise predictions about future sales help firms sidestep both stockouts and overstocking. By interpreting sales patterns, seasonal shifts, and buyer preferences, businesses can achieve balanced inventory levels—meeting consumer needs without tying up capital in stagnant products.

6) Inventory Management

Strategic oversight of inventory boosts financial health by aligning stock with market dynamics. Tracking item turnover rates allows companies to redeploy underperforming items, anticipate cyclical fluctuations, and optimize distribution to minimize waste or markdowns.

7) Supply Chain Management

Operational coordination serves as the backbone of end-to-end supply networks. It facilitates the seamless movement of resources from suppliers to factories, finished goods to retailers, and ultimately to end buyers. Weaknesses in this area often result in delayed shipments, financial setbacks, and workflow chaos.

Shape tomorrow's products: Dive into Product Management Training - Join now!

What is Logistics Management?

Logistics management is the strategic coordination of procuring, moving, and storing materials, components, and finished products from their origin to the end consumer. A widely recognised framework in this field is the 'Seven Rs,' which emphasises delivering:

1) The right product

2) In the right quantity

3) At the right time

4) In the right condition

5) To the right place

6) For the right customer

7) At the right cost

Mastering these principles ensures a business remains efficient and competitive.

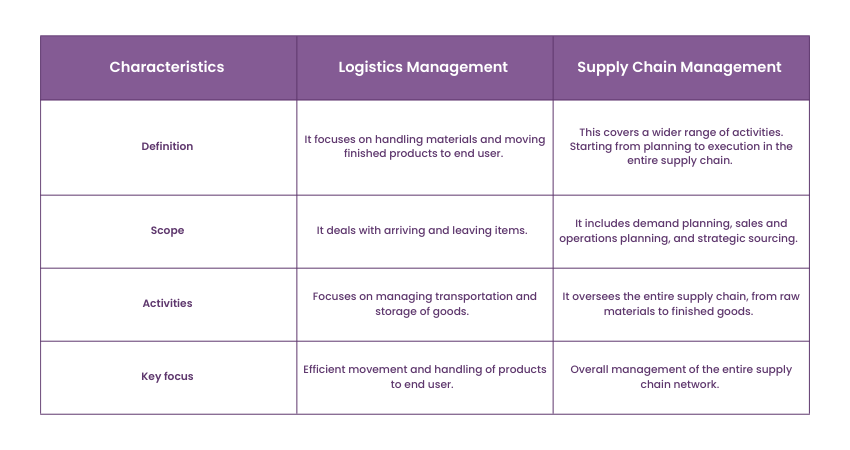

Difference Between Logistics and Supply Chain Management

Let’s simply the difference between Logistics and Supply Chain for you:

What is the Main Focus of Logistics?

The focus of logistics is the efficient planning, implementation, and management of the movement and storage of goods, services, and information from the point of origin to the destination. It ensures that the right products reach the right place at the right time while minimising costs and maximising customer satisfaction.

Logistics encompasses various functions, including transportation, warehousing, inventory management, order fulfilment, and supply chain coordination, all aimed at optimising efficiency and responsiveness in business operations.

What are the 7 Cs of Logistics?

The 7 Cs of logistics refer to key principles that ensure smooth supply chain operations: Correct Product, Correct Quantity, Correct Condition, Correct Place, Correct Time, Correct Customer, and Correct Cost. These elements ensure that businesses meet customer demands efficiently while maintaining cost-effectiveness.

By focusing on these principles, companies can streamline operations, enhance service quality, and reduce errors or delays in logistics processes, ultimately improving overall supply chain performance.

Conclusion

We hope after reading this blog, you now understand What is Logistics. It's evident that Logistics is not a mere cog in the business machine, but it's the very lifeblood. Its evolving nature, marked by upcoming trends and solutions to challenges, indicates its resilience and crucial role in shaping global commerce. As global connectivity increases, streamlined Logistics becomes ever more vital, solidifying its position in modern business.

Unlock your Logistics potential with our Logistics Management Training - Register today!

Frequently Asked Questions

What is the Role of Logistics?

Logistics ensures the efficient flow of goods, services, and information from origin to destination. It involves transportation, warehousing, inventory management, and order fulfilment to optimise costs, enhance customer satisfaction, and streamline supply chain operations, ensuring timely and accurate deliveries.

What is the Difference Between Logistics and Transport?

Logistics is the broader process of managing the supply chain, including procurement, storage, and distribution, while transport specifically refers to moving goods from one location to another. Transport is a key component of logistics, but logistics also involves planning, inventory control, and coordination.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 3,000 online courses across 490+ locations in 190+ countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are the Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various Business Skills Courses, including the Facilitation Skills Training, Floristry Training, Product Management Training, and Supply Chain Management Training. These courses cater to different skill levels, providing comprehensive insights into Supervisor Responsibilities.

Our Business Skills Blogs cover a range of topics related to Earned Value Management, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Project Management skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Skills Resources Batches & Dates

Date

Logistics Management Training

Logistics Management Training

Fri 21st Mar 2025

Fri 16th May 2025

Fri 18th Jul 2025

Fri 19th Sep 2025

Fri 21st Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please