We may not have the course you’re looking for. If you enquire or give us a call on +357 26030221 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Manual Handling, an integral aspect of many industries, involves physically lifting, moving, and transferring objects by hand. While essential, these tasks pose inherent risks to workers' health and safety. As workplaces strive to create environments prioritising employee well-being, understanding the Manual Handling Hierarchy becomes paramount. This guide will explore the Manual Handling Hierarchy and learn how a strategic approach can empower employers and employees to navigate Manual Handling challenges.

Table of Contents

1) Understanding Manual Handling

2) The Manual Handling Hierarchy Explained

a) Level 1: Elimination

b) Level 2: Substitution

c) Level 3: Engineering Controls

d) Level 4: Administrative Controls

e) Level 5: Personal Protective Equipment (PPE)

3) What is the Order of Management Hierarchy?

4) What are the Four Key Areas of Manual Handling?

5) Conclusion

Understanding Manual Handling

Manual Handling is a fundamental aspect of numerous industries, involving the physical exertion of lifting, carrying, pushing, or pulling objects by hand or bodily force. Understanding the complexities of this practice and being aware of the potential risks involved is crucial. Let's go over a few points:

a) Definition and Scope: Manual Handling encompasses a wide range of tasks, from lifting heavy boxes to simple actions like pushing a cart. It is not limited to specific job roles and is present across industries, from construction and manufacturing to healthcare and retail.

b) Importance: Proper Manual Handling is crucial to prevent injuries like musculoskeletal disorders, strains, sprains, and even more severe injuries resulting from improper lifting techniques.

c) Risk factors: Manual Handling risks can be influenced by various factors such as the weight and size of the load, how often it is handled, one's posture while carrying it, and the distance that needs to be covered. Awkward postures, repetitive motions, and lack of training can exacerbate these risks.

d) Ergonomics: Ergonomic principles play a vital role in minimising Manual Handling risks. Properly designed workspaces, tools, and equipment can reduce strain on the body.

e) Employee empowerment: Educating employees about correct lifting Manual Handling Techniques, the importance of using mechanical aids, and recognising early signs of strain empowers them to take an active role in their safety.

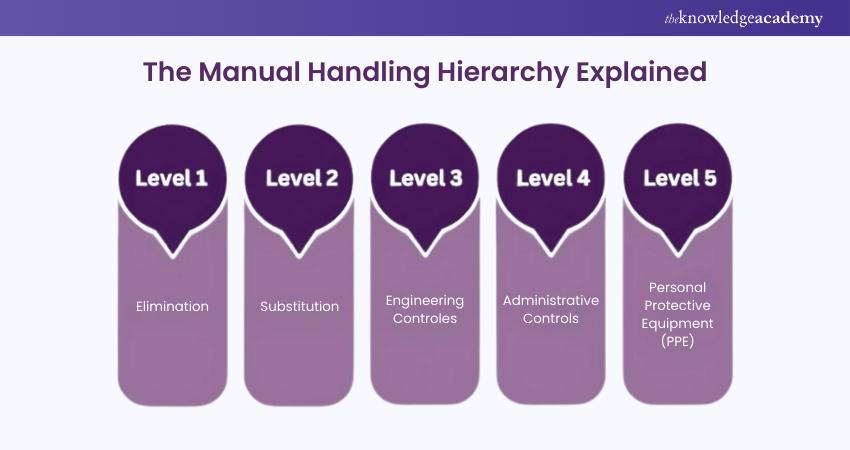

The Manual Handling Hierarchy Explained

Breaking down the hierarchy into five levels, we'll explain each step in detail:

Level 1: Elimination

The principle of avoidance forms the foundation of the Hierarchy of Manual Handling, which eliminates the need for Manual Handling tasks whenever possible. This proactive approach prioritises employee well-being and operational efficiency. Here's a breakdown of key points:

a) Task Redesign: Consider redesigning job tasks and workflows to minimise or eliminate the need for Manual Handling. Automation, reorganising processes, or introducing technology can reduce physical strain on employees.

b) Workstation Layout: Optimise workstation layout to ensure that tools, equipment, and materials are within easy reach, reducing the need for extensive movement and lifting.

c) Load Reduction: Reduce the weight and size of loads to manageable levels. Smaller, lighter loads are easier and safer to handle, lessening the risk of strain or injury.

d) Use of Assistive Tools: Integrate tools like conveyors, forklifts, and carts that can transport heavy items efficiently. Such aids minimise the physical demands on employees.

e) Training and Communication: Educate Employees about the importance of task avoidance and provide guidelines for identifying opportunities to avoid Manual Handling. Encourage open and effective communication to report potentially hazardous tasks.

f) Job Rotation: Implement job rotation to distribute Manual Handling tasks across employees. This not only reduces the physical strain on one individual but also enriches team members' skill sets.

g) Collaborative Efforts: Involve employees in identifying tasks that could be avoided. Their insights can lead to practical solutions that streamline processes and eliminate unnecessary physical strain.

h) Continuous Improvement: Regularly assess the effectiveness of avoidance strategies. Adapt to changing work requirements and technologies to optimise task avoidance measures continually.

i) Positive Impact: Successful avoidance reduces the risk of injuries and enhances overall productivity by streamlining operations and creating a safer work environment.

Learn about manual handling and safe lifting techniques, sign up for our Manual Handling At Work Training now!

Level 2: Substitution

In the Manual Handling Hierarchy, Level 2 focuses on systematically assessing Manual Handling tasks and implementing strategies to minimise risks. This method recognises that some tasks cannot be avoided but highlights the significance of recognising and minimising potential dangers.

a) Comprehensive Risk Assessment: Conduct thorough assessments of Manual Handling tasks to identify potential hazards. Consider factors like load weight, frequency, posture, and environmental conditions.

b) Involving Employees: Engage workers who perform Manual Handling tasks. Their insights can provide valuable information about task intricacies and potential risks.

c) Hierarchy of Controls: Apply the hierarchy of controls to prioritise risk reduction. Start with engineering controls, like adjusting workstations or load sizes, and progress to administrative controls if engineering solutions are not feasible.

d) Ergonomic Considerations: Ensure that workspaces are ergonomically designed to reduce strain on the body. This involves proper workstation layout, adjustable equipment, and promoting correct posture.

e) Load Management: Implement guidelines for safe lifting and carrying Manual Handling Techniques. Educate employees on distributing weight evenly, maintaining a neutral spine, and avoiding sudden movements.

f) Training and Education: Offer training programs that educate employees about the risks associated with Manual Handling and the importance of adhering to safe practices.

g) Regular Review: Continuously monitor Manual Handling tasks and their associated risks. Regular reviews enable the identification of emerging hazards and the adaptation of control measures.

h) Feedback Loop: Establish a feedback mechanism where employees can report challenges or suggestions related to Manual Handling. This promotes a collaborative environment for improving safety measures.

i) Data-driven Approach: Utilise data from incident reports and Manual Handling Risk Assessments to make informed decisions about implementing targeted control measures.

Create a culture of proactivity in terms of health and safety at workplace, sign up for our Health & Safety in the Workplace Training now!

Level 3: Engineering Controls

In the Manual Handling Hierarchy, Level 3 introduces the integration of mechanical aids as a strategic approach to reducing physical strain and enhancing safety. Mechanical aids play a pivotal role in alleviating the demands of Manual Handling tasks, promoting efficiency and minimising the risk of injuries.

a) Types of Mechanical Aids: It is important to educate employees about various mechanical aids like trolleys, hoists, conveyors, and lifting equipment. These aids are specifically designed to tackle different Manual Handling tasks.

b) Load Transportation: Encourage trolleys and carts to transport heavy or bulky items. This reduces the need for manual lifting and carrying, significantly decreasing the risk of strains and sprains.

c) Lifting Assistance: Introduce lifting equipment like cranes or hoists for tasks involving heavy loads. These aids minimise the physical effort required from employees.

d) Ergonomic Design: Ensure that mechanical aids are ergonomically designed to promote natural movements and posture, further reducing strain on the body.

e) Proper Training: Provide comprehensive training on the correct usage of mechanical aids. Employees should understand how to operate and maintain these tools safely.

f) Maintenance: Establish regular maintenance protocols to ensure mechanical aids are in optimal working condition. Faulty equipment can pose risks to both employees and the operation.

g) Risk Reduction: Mechanical aids reduce the risk of injuries and improve task efficiency, contributing to increased productivity.

h) Custom Solutions: Explore custom-designed mechanical aids tailored to specific tasks or industries. These solutions can address unique challenges effectively.

i) Cultural Acceptance: Promote a culture where employees view mechanical aids as assets rather than hindrances. Address any misconceptions and concerns that may arise during the adoption process.

Level 4: Administrative Controls

In the Manual Handling Hierarchy, Level 4 highlights the significance of comprehensive training and education using administrative control as a foundational strategy for minimising Manual Handling risks. Proper training equips employees with the knowledge and skills to perform tasks safely, promoting a culture of awareness and responsibility.

a) Importance of Education: Emphasise that informed employees are better equipped to identify potential hazards, apply safe practices, and make informed decisions while performing Manual Handling tasks.

b) Lifting Techniques: Provide training on correct lifting techniques, maintaining a neutral spine, bending the knees, and distributing weight evenly.

c) Posture and Movement: Educate employees on maintaining proper posture and avoiding awkward movements that contribute to strains.

d) Risk Recognition: Train employees to recognise tasks with potential risks and to communicate concerns to supervisors or safety officers.

e) Task-specific Training: Tailor training to specific job roles, considering the unique challenges they face in Manual Handling. This ensures relevance and applicability.

f) Interactive Learning: Use hands-on training sessions, workshops, and simulations to engage employees in learning safe practices.

g) Supervisor Involvement: Involve supervisors in training efforts, as they play a crucial role in reinforcing safe practices and setting an example for their teams.

h) Regular Refresher Courses: Offer periodic refresher courses to reinforce safe practices, address misconceptions, and update employees on the latest safety protocols.

i) Documentation: Maintain records of training sessions and employee participation. This documentation serves as evidence of Compliance and ongoing efforts to ensure safety.

Learn the importance of ladder safety at the workplace, sign up for our Ladder Safety Training now!

Level 5: Personal Protective Equipment (PPE)

The Manual Handling Hierarchy's final tier stresses the significance of Personal Protective Equipment (PPE) as the ultimate safeguard against Manual Handling Hazards. PPE serves as a critical safeguard when other strategies cannot eliminate hazards.

a) Identifying Appropriate PPE: Determine the specific PPE required for Manual Handling tasks based on the associated risks. This might include gloves, back support belts, knee pads, or anti-vibration gloves.

b) Fitting and Comfort: Ensure that the selected PPE fits well and is comfortable for employees. Ill-fitting equipment can hinder movement and lead to discomfort.

c) Training on PPE Usage: Provide training on PPE's correct application, use, and limitations. Employees should understand when and how to use each type of equipment.

d) Regular Inspection: Implement routine checks to ensure PPE is in good condition and functioning correctly. Damaged or faulty equipment should be replaced promptly.

e) Employee Awareness: Educate employees about the role of PPE in reducing risks and protecting their well-being. Please encourage them to report any issues related to PPE.

f) SupervisorOversight: Encourage supervisors to monitor PPE usage and ensure employees adhere to safety protocols.

g) Risk reduction Approach: Emphasise that PPE is not a standalone solution but an additional layer of protection. It should be used in conjunction with other strategies from the hierarchy.

h) Emergency Situations: Train employees on the correct procedures to follow in emergencies, including when to use PPE to protect themselves and others.

i) Evaluation and Upgrades: Regularly assess the effectiveness of PPE in mitigating risks. Upgrade or replace equipment if better options become available.

What is the Order of Management Hierarchy?

The order typically includes top-level (executives like CEOs), middle-level (managers overseeing departments), and lower-level (supervisors managing frontline staff). This structure ensures decision-making flows from strategic planning to operational execution.

What are the Four Key Areas of Manual Handling?

These include lifting (correctly managing heavy items), carrying (maintaining balance and posture), pushing and pulling (using proper techniques to avoid strain), and team handling (coordinating tasks effectively with others).

Conclusion

The Manual Handling Hierarchy presents a systematic approach to safeguarding employees and enhancing workplace efficiency. Implementing these strategies reduces injuries and promotes a collaborative environment that values employee well-being and operational excellence.

Elevate your understanding of Fire Safety principles and practices today with our Fire Safety Training – Sign up now!

Frequently Asked Questions

Common injuries include back pain (from improper lifting), musculoskeletal disorders (affecting muscles and joints), hernias (due to excessive strain), sprains and strains (from sudden movements), and cuts or bruises (from dropped or mishandled loads).

This refers to tasks involving heavy, awkward, repetitive, or unstable loads, which pose risks of injury. Poor technique, inadequate training, or unsafe conditions can lead to harm, especially to the back and joints.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Health & Safety in the Workplace, including Health and Safety in the Workplace Training, Advanced First Aid Training and Working at height training. These courses cater to different skill levels, providing comprehensive insights into Workplace Health and Safety.

Our Health & Safety Blogs cover a range of topics offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Health & Safety skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

Manual Handling at Work

Manual Handling at Work

Fri 24th Jan 2025

Fri 28th Mar 2025

Fri 23rd May 2025

Fri 25th Jul 2025

Fri 26th Sep 2025

Fri 28th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please