We may not have the course you’re looking for. If you enquire or give us a call on +420 210012971 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

ISO 45001 is a globally recognised standard that sets criteria for implementing an effective Occupational Health and Safety (OH&S) management system. An essential part of this standard is the ISO 45001 PDCA which helps organisations effectively manage workplace health and safety. It provides a systematic approach to managing occupational health and safety risks, ensuring compliance with relevant regulations, and promoting a culture of continuous improvement.

The Health and Safety at Work report states 99 per cent of all workplace accidents are preventable. You can prevent workplace accidents by following a proper safety framework. In this blog, you will learn the ISO 45001 PDCA model, the steps involved, and its benefits.

Table of Contents

1) What is the ISO 45001 PDCA model?

2) Steps involved in the PDCA cycle

a) Plan phase

b) Do phase

c) Check phase

d) Act phase

3) Benefits of implementing the PDCA cycle

4) Conclusion

What is the ISO 45001 PDCA model?

The ISO 45001 Plan-Do-Check-Act model is a systematic approach for continual improvement in occupational health and safety management systems. It provides organisations with a framework to plan, implement, monitor, and enhance their processes, ensuring workplace health and safety management.

ISO 45001 is an internationally recognised occupational health and safety management system framework. It provides a standard that organisations can follow to build and nurture a healthy and safe work environment.

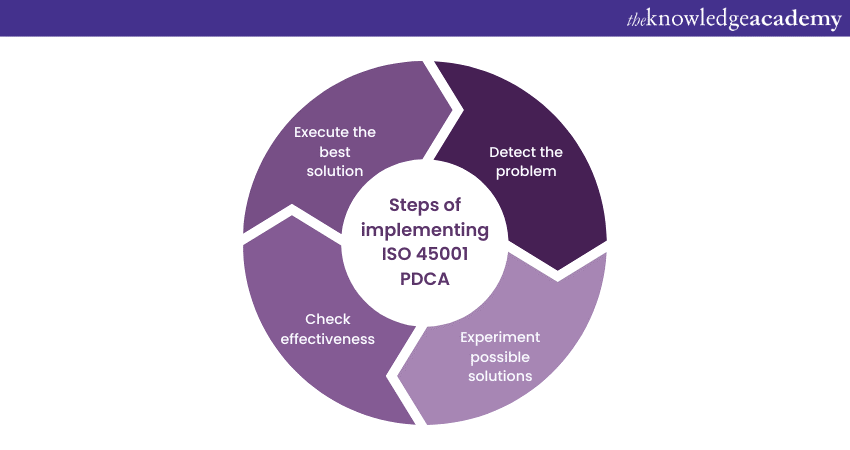

Steps involved in the PDCA cycle

ISO 45001 incorporates the PDCA cycle as a fundamental approach to managing occupational health and safety. The standard requires organisations to establish and maintain processes that follow the PDCA cycle, ensuring that continual improvement is at the core of their management system. Here are the steps involved in the PDCA Cycle:

Plan phase

In this phase, organisations establish the objectives and actions necessary to achieve the expected results. This involves identifying hazards, assessing risks, and developing mitigation plans and procedures. During this phase, organisations set measurable targets, define roles and responsibilities, and allocate resources accordingly.

Unlock your potential in occupational health and safety with the industry-leading ISO 45001 Certification – Signup now and elevate your career today!

Do phase

The Do phase involves implementing the plans developed in the previous phase. It includes the execution of the processes, training employees, and ensuring the availability of necessary resources. This phase is crucial for translating plans into action and implementing the intended changes.

Check phase

The Check phase monitors and evaluates the implemented processes and their outcomes. It involves measuring performance against set objectives, conducting internal audits, and collecting data for analysis. This phase helps organisations identify areas for improvement, detect non-conformities, and assess the effectiveness of their occupational health and safety management system.

Act phase

The Act phase involves taking corrective actions based on the findings from the previous phase. Organisations analyse the collected data, identify root causes of issues, and implement corrective and preventive measures. This phase emphasises the importance of learning from experiences, adjusting processes as necessary, and striving for continual improvement.

Learn the purpose and principles of ISO 45001 with our ISO 45001 Lead Auditor courses. Join now!

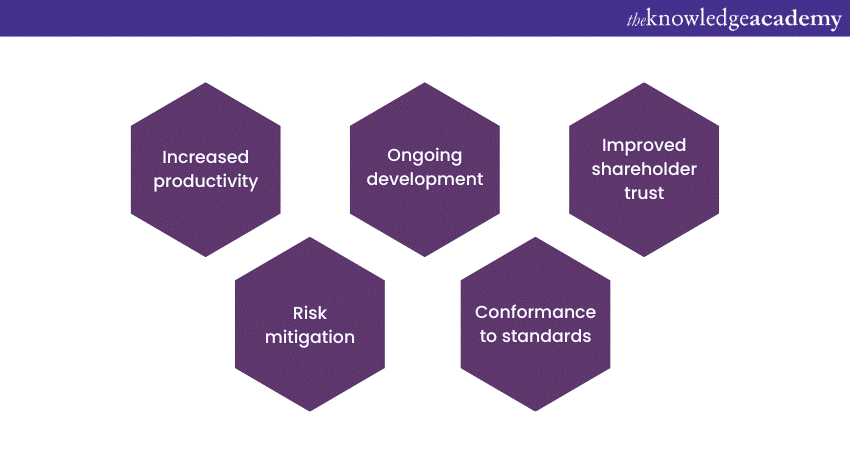

Benefits of implementing the PDCA cycle

Implementing the PDCA cycle within the ISO 45001 framework offers several benefits for organisations. Here are the benefits of implementing the PDCA cycle:

a) Continual improvement: The PDCA cycle provides a structured approach for organisations to continuously improve their occupational health and safety management system.

b) Risk reduction: By following the PDCA cycle, organisations can systematically identify and mitigate occupational health and safety risks, reducing the likelihood of incidents and accidents.

c) Compliance with regulations: The PDCA cycle helps organisations ensure compliance with industry regulations and legal requirements, promoting a culture of responsible and lawful operations.

d) Enhanced efficiency: The PDCA cycle allows organisations to streamline their processes, optimise resource allocation, and improve overall operational efficiency.

e) Stakeholder confidence: Implementing the PDCA cycle demonstrates an organisation's commitment to maintaining a safe and healthy work environment, enhancing stakeholder confidence and trust.

Master the skills to lead the successful implementation of ISO 45001 and drive workplace safety with our comprehensive ISO 45001 Lead Implementer Training - Signup today!

Conclusion

The ISO 45001 PDCA cycle is vital in ensuring the effectiveness of occupational health and safety management systems. Organisations can continuously improve their processes, mitigate risks, and enhance workplace safety by following the four-step approach of Plan, Do, Check, and Act.

Sign up for our ISO 45001 Foundation Training and take the right step towards becoming a occupational health and safety management expert

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please