We may not have the course you’re looking for. If you enquire or give us a call on +49 8000101090 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

The Evolution of Six Sigma principles has led to a breakthrough in efficient quality control. It aims to provide high-quality Project Management to organisations across industries. Six Sigma is a statistics-based approach to reducing variation and defects using data-driven decision-making.

However, many modern-day organisations are unaware of the rich history of this approach, and thus, they remain sceptical while implementing this approach. But not anymore; if your organisation is considering implementing the Six Sigma approach, then this blog is for you. In this blog, you will learn about the Evolution of Six Sigma from its humble beginnings to its modern iterations. Let's explore Six Sigma!

Table of Contents

1) What is Six Sigma?

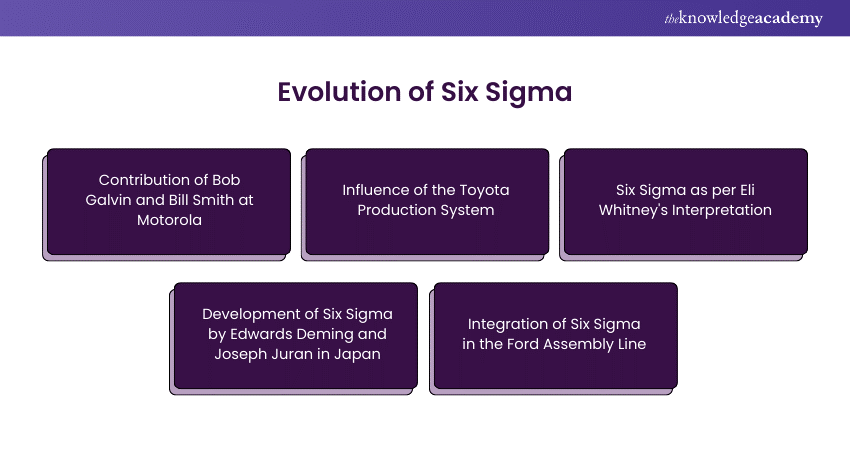

2) Evolution of Six Sigma: An overview

a) Contribution of Bob Galvin and Bill Smith at Motorola

b) Influence of the Toyota Production System

c) Six Sigma, as per Eli Whitney's Interpretation

d) Development of Six Sigma by Edwards Deming and Joseph Juran in Japan

e) Integration of Six Sigma in the Ford Assembly Line

3) Conclusion

What is Six Sigma?

Six Sigma is a process that mainly deals with producing high-quality goods and services. It aims to minimise defects and variations in processes to achieve high-quality outputs consistently. High-quality goods increase trust among customers, therefore boosting the productivity of the business.

Six Sigma is mainly based on a statistical theory developed by the German Mathematician Friedrich Gauss. A Gaussian Distribution, also referred to as a Normal Distribution, is a type of continuous probability distribution where the data points cluster around the mean, forming a symmetrical bell-shaped curve. The farther an observation is from the mean, the lower its probability of occurring. Thus, by applying the Six Sigma principles, professionals can reduce deviations on the curve and thus optimise efficiency.

Evolution of Six Sigma: An overview

The Evolution of Six Sigma can be traced back to the times when only one single skilled labourer made one product. However, all of this changed as Industrialisation became the norm. Industrialisation led to mass production of goods, which meant division of labour.

The manufacturing process involved a series of activities done by many people. This involved departmentalisation of the labour. The biggest advantage of this method was that commodities could be mass-produced.

Though mass production became a norm, the need to check the quality of the product also started to increase. The success of a business is measured by expanding production while decreasing defective products.

Thus, the concept of Six Sigma was born. It developed over time and in each iteration and has undergone a significant change since then. The first person to propose ideas based on the Six Sigma principles was Eli Whitney during the late 17th century, and its latest iteration is still being updated to date. To learn more about the Evolution of Six Sigma, let us investigate its various models that have become famous over the years:

Contribution of Bob Galvin and Bill Smith at Motorola

In the 1980s, a revamped Motorola leadership strived for excellence in quality. This is where Bob Galvin and Bill Smith enter the picture. Bob and Bill were the first to pitch the idea that a product would only go to design when the specifications were up to the mark set by process control.

Motorola Corporation became the first organisation to expand the previous ‘Three Sigma’ principles to ‘Six Sigma’ principles. Statistically, a mean of Six Sigmas would encompass 99.99% of all output, resulting in 0.02 defects, which effectively negates it to zero.

By using these Six Sigma principles, Motorola was able to minimise its defects to 3.4 per million opportunities successfully. This brought about a never-seen success, and it was not too late before other companies like IBM, Kodak, and Xerox incorporated the Six Sigma principles in their repertoire.

Improve your organisational efficiency through our Six Sigma Green Belt Course!

Influence of the Toyota Production System

It would not be wrong to say Motorola introduced the Six Sigma principles, but it was Toyota who perfected them. Toyota mainly used the Six Sigma principles to minimise the cost of production and eliminate waste. Even today, most companies use its principles to minimise waste, but Toyota employs Six Sigma to optimise manufacturing processes.

Six Sigma as per Eli Whitney's Interpretation

Even before the term Six Sigma was coined, its core principles were used to maximise efficiency. Famed American inventor Eli Whitney was one of the first to use this system. He called it the Uniformity System, and this is where it all began.

When the French Government ordered 10,000 muskets from him, he came up with an idea- Interchangeable Parts. He came up with designs for standardised parts, thus paving the way to what is modernly called- Mass Production. Whitney’s Uniformity System gained popularity and was adopted by the military-industrial complex and defence sectors across Europe and America.

Development of Six Sigma by Edwards Deming and Joseph Juran in Japan

Post World War II, the Japanese had the Herculean task of rebuilding the nation. The Japanese believed the Allies succeeded because they had a strong industrial infrastructure in the West driven by a quality assurance mechanism.

They sought Edwards Deming's services to help them rebuild the economy. Deming introduced the concept of the Plan-Do-Check-Act (PDSA) cycle and trained native engineers and managers thoroughly to implement the Six Sigma principles.

Joseph Juran, through his ‘A Quality Control Handbook’, suggested that a team of inspectors, statisticians and surveyors must exist at every level of a company. Termed Big Q, these teams were integrated into a company seamlessly, and quality was easily attained through active management. This is the reason Juran’s approach is used to date as a prime example of how efficiently the Six Sigma principles work.

Integration of Six Sigma in the Ford Assembly Line

The mass production of automobiles spearheaded by Ford led to cost-effective mass manufacturing. This brought an immediate requirement for the measurement of parts against pre-determined standards.

Random sampling became a common practice as a form of quality control. This resulted in the mass production of interchangeable parts across industries. This led to acceptable tolerance limits in production, which, in turn, resulted in quicker production. This is how Ford became one of the first companies to incorporate statistical tools in the management of quality and, eventually, entire departments for quality control.

Increase business productivity with our Six Sigma Black Belt Course - join now!

Conclusion

Through this blog, we have chartered the beginnings and Evolution of Six Sigma. These principles are the guiding force behind many successful businesses. By understanding how these principles evolved, we can appreciate the different iterations it has taken over the years. By incorporating Six Sigma principles, a business can only grow stronger and increase its efficiency considerably.

Master Six Sigma Principles with our Six Sigma Master Black Belt Course - join now!

Frequently Asked Questions

The term Six Sigma was first introduced by American Engineer Bill Smith while working at Motorola in 1986. The application of Six Sigma principles can be seen as early as the 18th century in inventor Eli Whitney’s works. Today, these can be seen incorporated in every successful business in one form or the other.

The White belt is the first level in Six Sigma, followed by Yellow, Green, Black and ending with a Master Black belt.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Six Sigma Certification Training, including Six Sigma Green Belt, Six Sigma Black belt and Six Sigma Yellow Belt Courses. These courses cater to different skill levels, providing comprehensive insights into Six Sigma Belts.

Our Business Improvement Blogs covers a range of topics related to Six Sigma, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Business Improvement skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Lean Six Sigma Green Belt

Lean Six Sigma Green Belt

Mon 25th Nov 2024

Mon 2nd Dec 2024

Sat 7th Dec 2024, Sun 8th Dec 2024

Mon 9th Dec 2024

Mon 16th Dec 2024

Mon 6th Jan 2025

Mon 13th Jan 2025

Mon 20th Jan 2025

Mon 27th Jan 2025

Mon 3rd Feb 2025

Mon 10th Feb 2025

Mon 17th Feb 2025

Mon 24th Feb 2025

Mon 3rd Mar 2025

Mon 10th Mar 2025

Mon 17th Mar 2025

Mon 24th Mar 2025

Mon 31st Mar 2025

Mon 7th Apr 2025

Mon 14th Apr 2025

Tue 22nd Apr 2025

Mon 28th Apr 2025

Tue 6th May 2025

Mon 12th May 2025

Mon 19th May 2025

Tue 27th May 2025

Mon 2nd Jun 2025

Mon 9th Jun 2025

Mon 16th Jun 2025

Mon 23rd Jun 2025

Mon 30th Jun 2025

Mon 7th Jul 2025

Mon 14th Jul 2025

Mon 21st Jul 2025

Mon 28th Jul 2025

Mon 4th Aug 2025

Mon 11th Aug 2025

Mon 18th Aug 2025

Tue 26th Aug 2025

Mon 1st Sep 2025

Mon 8th Sep 2025

Mon 15th Sep 2025

Mon 22nd Sep 2025

Mon 29th Sep 2025

Mon 6th Oct 2025

Mon 13th Oct 2025

Mon 20th Oct 2025

Mon 27th Oct 2025

Mon 3rd Nov 2025

Mon 10th Nov 2025

Mon 17th Nov 2025

Mon 24th Nov 2025

Mon 1st Dec 2025

Mon 8th Dec 2025

Mon 15th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please