We may not have the course you’re looking for. If you enquire or give us a call on +45 89870423 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Are you looking to enhance your problem-solving skills? Do you wish to contribute to process improvement within your organisation? If so, you should consider exploring Six Sigma Project ideas.

The various Six Sigma Projects provide a structured approach to problem-solving and process improvement that follows the principles of the Six Sigma methodology. However, choosing projects that align with your organisation's strategic goals is also essential if you are a beginner.

So embark on your Six Sigma journey and make a difference within your organisation. Read this blog to learn about Six Sigma Project ideas. Explore different tools and techniques that Six Sigma has to offer to deliver exceptional results.

Table of Contents

1) Six Sigma Projects – An overview

2) What does an effective Six Sigma Project look like?

3) Applications of Six Sigma Projects across industries

4) Beginner friendly Six Sigma Project ideas

5) How to begin with Six Sigma Projects?

6) Conclusion

Six Sigma Projects – An overview

Six Sigma is a renowned methodology that has revolutionised process improvement in various industries. It offers a structured and data-driven approach to identify and eliminate defects, reduce process variations, and enhance overall operational performance.

Its projects are central to the success of Six Sigma, which serves as the driving force behind continuous improvement efforts. These projects are carefully planned initiatives that focus on improving specific processes within an organisation.

They aim to achieve measurable and significant quality, efficiency, and customer satisfaction improvements. Furthermore, the projects follow a defined set of steps, often referred to as the Define, Measure, Analyse, Improve, and Control (DMAIC) or Define, Measure, Analyse, Design, and Verify (DMADV) methodology, depending on the nature of the project.

What does an effective Six Sigma Project look like?

Implementing Six Sigma Projects requires careful planning and execution to ensure successful outcomes. Such projects possess several key characteristics that contribute to their effectiveness and impact. The following are some characteristics that make these projects successful:

Clearly defined problem or opportunity

A good project begins with clearly articulating the problem statement in a precise and measurable manner. A clear understanding of the problem at hand gives the project team insight into their efforts to implement solutions.

Data-driven approach

Data is the foundation of Six Sigma Projects. Using statistical tools and techniques, the project team can identify root causes, measure process performance, and accurately monitor improvements. Therefore, it ensures that decisions are based on objective evidence rather than assumptions or opinions.

Realistic scope and objectives

A good Six Sigma Project is crucial to set clear expectations and establish measurable goals to track progress effectively. It helps the team in making meaningful improvements without spreading themselves too thin.

Cross-functional team collaboration

Successful Six Sigma Projects involve collaboration among individuals from different functional areas within the organisation. This cross-functional approach brings diverse perspectives, expertise, and insights to the project. As a result, the team is encouraged to develop comprehensive and effective solutions.

Leadership support and engagement

Leaders should actively participate and demonstrate their commitment to the project's goals and objectives. Their support helps remove barriers, allocate necessary resources, and create a culture that focuses on continuous improvement in the organisation.

Continuous monitoring and control

Another quality of a Six Sigma Project is emphasising continuous monitoring and control to sustain improvements over time. Establishing appropriate metrics and Key Performance Indicators (KPIs) to measure progress is essential. This way, the team can detect deviations or regressions quickly and take corrective actions.

Stakeholder engagement and communication

Engaging stakeholders throughout the project lifecycle is crucial for success. A good communication system in a Six Sigma Project ensures that all relevant parties are informed about the project's progress, outcomes, and potential impacts. This further helps gain support, manage expectations, and incorporate valuable feedback into the project.

Focus on sustainable results

In the development process, it is not just about implementing quick fixes but also establishing robust processes and systems that consistently deliver desired outcomes. The project team should develop strategies to ensure the improvements are embedded into the organisation's culture and practices for the long term.

Continuous learning and adaptation

A good Six Sigma Project also provides valuable opportunities for learning and growth. They encourage the team to learn from successes and failures, adapt their approaches, and continuously refine their problem-solving skills. Therefore, the team can constantly improve their capabilities and drive future project successes.

Enhance your problem-solving abilities, statistical analysis skills, and leadership capabilities. Join our Six Sigma Black Belt Upgrade course.

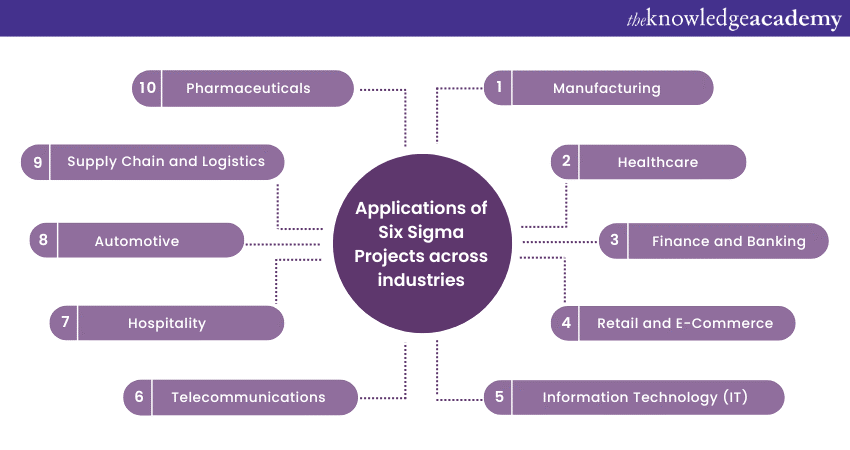

Applications of Six Sigma Projects across industries

The Six Sigma Projects find application across various industries, helping organisations improve their processes, enhance quality, and increase customer satisfaction. Here are some key applications of Six Sigma Projects across industries:

a) Manufacturing: Six Sigma Project in this industry focuses on reducing defects, improving production efficiency, and streamlining supply chain processes.

b) Healthcare: In this industry, such projects target reducing medical errors, improving patient safety, and enhancing the efficiency of healthcare delivery.

c) Finance and Banking: Six Sigma Projects in the Finance and Banking industry aim to improve accuracy and reduce processing times. They also enhance customer service in loan processing, risk management, fraud prevention, and other such areas.

d) Retail and E-Commerce: Six Sigma Projects in the retail and e-commerce sectors focus on optimising inventory management, reducing order processing errors, and enhancing the customer experience.

e) Information Technology (IT): In the IT industry, these projects aim to improve software development processes, reduce system downtime, and enhance customer support services.

f) Telecommunications: Six Sigma Projects in this industry target improving network reliability, reducing customer service response times, and enhancing service quality.

g) Hospitality: In the Hospitality industry, they focus on improving guest satisfaction, streamlining hotel operations, and enhancing service delivery.

h) Automotive: The Six Sigma Projects in this industry aim to reduce defects in manufacturing processes, improve vehicle reliability, and enhance overall product quality.

i) Supply Chain and Logistics: Here, Six Sigma Projects help optimise inventory management, reduce lead times, and enhance overall supply chain efficiency.

j) Pharmaceuticals: In the Pharmaceutical industry, Six Sigma Projects focus on improving drug development processes, ensuring compliance with regulations, and enhancing product quality and safety.

Learn how to use the Six Sigma methodology to achieve business objectives with our Six Sigma Certification Training.

Beginner friendly Six Sigma Project ideas

Six Sigma Projects are categorised into different types based on the nature of the problem, the goals of the project, and the stage of the process being addressed. Understanding these types can help organisations apply the Six Sigma methodology effectively to drive improvement and achieve desired outcomes. Here are some common types of Six Sigma Project ideas:

DMAIC Projects

Define, Measure, Analyse, Improve, and Control (DMAIC) projects are the most common types. They improve existing processes by identifying and reducing variations, defects, or inefficiencies. They also follow a structured approach that involves:

a) Defining the problem

b) Collecting and analysing data

c) Implementing improvements

d) Establishing control measures to sustain the improvements

DMADV Projects

Define, Measure, Analyse, Design, and Verify (DMADV) projects, also known as Design for Six Sigma (DFSS) projects. These Six Sigma Projects are undertaken when organisations aim to develop new processes, products, or services.

Further, these projects follow a systematic approach to design and develop processes that meet customer requirements and have high quality and reliability. They are particularly relevant for organisations seeking innovation or launching new initiatives.

Lean Six Sigma Projects

Lean Six Sigma Projects combine the Six Sigma Principles and tools with Lean Methodologies. These projects focus on reducing defects and variations, eliminating waste, and improving process flow.

Lean Six Sigma Projects also aim to optimise processes, enhance customer value, and maximise efficiency. It is worth noting that they often involve streamlining processes, reducing cycle times, and improving overall productivity.

Kaizen Projects

Kaizen projects, also known as continuous improvement projects, emphasise making small incremental improvements on an ongoing basis. These Six Sigma Projects involve cross-functional teams and aim to address day-to-day process issues, improve productivity, and foster a culture of constant improvement within the organisation. Such projects also focus on empowering employees at all levels. They help the employees identify and implement improvements in their work areas.

Gain a comprehensive understanding of the principles and methodologies of Six Sigma with our Six Sigma Black Belt Course.

Green Belt Projects

Green Belt projects are undertaken by professionals who hold the Six Sigma Green Belt. They work under the guidance of Black Belts (highly trained and experienced in the Six Sigma methodology).

These projects are typically smaller in scale but still contribute to process improvement and organisational goals. Green Belt Projects focus on specific process areas or issues within the organisation. They offer data analysis, problem-solving, and improvement implementation to the users.

Quick Win Projects

Quick Win Projects address process improvement opportunities that require minimal time and resources but yield immediate results. These Six Sigma Projects are designed to achieve small-scale improvements quickly.

As a result, they help boost morale and showcase the benefits of the Six Sigma approach. These projects are ideal for beginners to gain confidence and demonstrate the value of the Six Sigma methodology.

Process Design Projects

These projects involve designing new processes or re-designing the existing processes to optimise efficiency and quality. These aims to align processes with organisational goals, customer requirements, and industry best practices.

Additionally, they require a thorough analysis of the current state and identification of improvement opportunities. They also involve developing a future state process that delivers enhanced results.

Process Redesign Projects

Process Redesign Projects focus on transforming and improving existing processes that are inefficient, error-prone, or fail to meet customer expectations. They aim to achieve significant process enhancements, improving quality, reducing costs, and increasing customer satisfaction. These projects involve the following:

Infrastructure Implementation Projects

Another project in Six Sigma is Infrastructure Implementation. It involves implementing Six Sigma Tools, technologies, or systems to support Six Sigma initiatives. These projects primarily focus on establishing the necessary infrastructure, such as data collection systems and statistical analysis software. Infrastructure Implementation Projects also ensure the organisation has the resources and capabilities to execute Six Sigma Projects effectively.

Supplier Relationship Improvement Projects

Such projects aim to enhance collaboration and communication with suppliers. They also help ensure the delivery of high-quality inputs. Further, these projects involve:

a) Establishing clear quality standards

b) Conducting regular performance evaluations

c) Implementing continuous improvement initiatives with suppliers

Additionally, Supplier Relationship Improvement Projects contribute to overall process stability and customer satisfaction by ensuring the reliability of the supply chain.

Elevate your leadership, strategic thinking, and problem-solving skills to drive transformative change in your organisation. Join our Six Sigma Master Black Belt course today!

How to begin with Six Sigma Projects?

Embarking on Six Sigma Projects can be an exciting and rewarding journey towards process improvement and organisational success. If you are a beginner, getting started with the projects in Six Sigma requires careful planning and thoughtful execution. Here are some essential steps to help you begin your Six Sigma Project effectively:

1) Identify a suitable project

Selecting the right Six Sigma Project is critical to your success. Therefore, it’s crucial to do the following before beginning the project:

a) Look for opportunities within your organisation where improvements can be made in terms of quality, efficiency, or customer satisfaction

b) Consider projects that align with the organisation's strategic goals and have a significant impact

c) Start with smaller, manageable projects as a beginner to gain experience and build confidence

2) Define its Six Sigma Project scope

Clearly defining the project scope involves the following:

a) Identify the specific process or area that needs improvement

b) Set boundaries for your project

c) Avoid overly broad or vague scopes that can lead to project inefficiencies or lack of focus

A well-defined scope ensures that you can allocate appropriate resources and measure progress effectively.

Drive success through data-driven decision-making with our Six Sigma Green Belt Course.

3) Assemble a project team

As the next step in your Six Sigma Project, you need to do the following:

a) Form a team of individuals with diverse skills and knowledge relevant to the project

b) Consider including representatives from different departments or functional areas to ensure a holistic approach

c) Assign roles and responsibilities within the team, including a project leader or champion who will provide guidance and support throughout the project

4) Define measurable objectives and metrics

In step four, the team is engaged in the following activities:

a) Set specific, measurable objectives for your project

b) Define metrics that will help you track progress and measure the project’s success

c) Ensure that the objectives are realistic and achievable within the project’s timeline and available resources

These objectives and metrics should be aligned with the problem you're addressing and the desired outcomes.

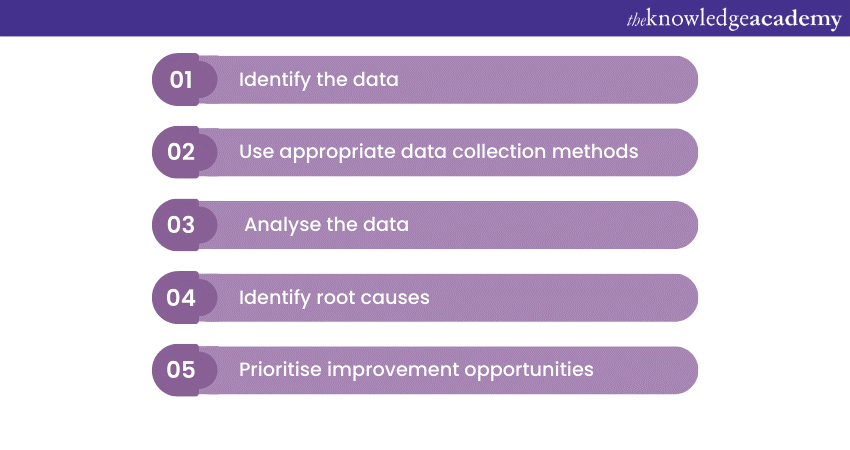

5) Collect and analyse data

Data collection and analysis are fundamental to projects in Six Sigma it includes the following:

a) Identify the data you need to measure the process and performance

b) Use appropriate data collection methods, such as sampling or direct measurement

c) Analyse the data using statistical tools and techniques to gain insights into the process

d) Identify root causes

e) Prioritise improvement opportunities

6) Generate improvement ideas

Based on the data analysis, generate improvement ideas that address the root causes of the identified issues. You must do the following:

a) Encourage brainstorming sessions with the project team to gather diverse perspectives and ideas

b) Evaluate the feasibility and potential impact of each improvement idea

c) Select the most promising ideas to implement as part of your project

7) Implement and monitor improvements

Once you've selected the improvement ideas, develop an implementation plan. You will need to do the following:

a) Assign tasks to team members

b) Establish timelines

c) Allocate necessary resources

d) Implement the improvements while closely monitoring their impact on the process

e) Use control charts, process monitoring tools, or other relevant methods to track the process performance

f) Ensure that the improvements are sustained over time

Unlock the power of process improvement and quality management with Six Sigma Yellow Belt course.

Conclusion

As a beginner, exploring the different types of Six Sigma Projects can provide you with a roadmap for improvement initiatives within your organisation. As a result, you can contribute to organisational success and drive continuous improvement efforts. So, embrace the power of Six Sigma and embark on your journey to excellence.

Gain the skills to solve and maintain the problems in Six sigma project with our DMAIC Training.

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please