We may not have the course you’re looking for. If you enquire or give us a call on +34 932716793 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Manual Handling is a fundamental aspect of various industries involving the lifting, moving, and transporting objects by hand. Although it may appear routine, improper manual handling can cause serious injuries and lasting health problems. Therefore, understanding the 5 Key Principles of Manual Handling is paramount for ensuring the safety and well-being of employees.

According to Statista, there were about 18 workplace fatalities in Great Britain in 2022 due to accidents while moving objects. Understanding Manual Handling principles can help mitigate such incidents. Want to know more? Read this blog to learn about the 5 Key Principles of Manual Handling in great detail. Let’s delve in deeper to learn more about it!

Table of Contents

1) What is Manual Handling?

2) Top 5 Key Principles of Manual Handling

a) Plan

b) Position

c) Pick

d) Proceed

e) Place

3) Conclusion

What is Manual Handling?

Manual Handling refers to any task that involves moving or supporting a load using your hands or physical strength. It includes actions like lifting, carrying, pushing, pulling, throwing, placing, or holding loads.

Common examples of Manual handling are lifting boxes, assembling items, pushing trolleys, packing goods, or using heavy tools. It can also include bending to scan items, washing dishes, or lifting people or animals.

Top 5 Key Principles of Manual Handling

An easy way to remember the principles of manual handling is by following the 5 Ps: Plan, Position, Pick, Proceed, and Place. Let’s look at each one:

Plan

Planning is the crucial initial step that lays the foundation for safe Manual Handling practices. It is the first of the 5 Key Principles of Manual Handling that suggest that before engaging in any lifting or moving task, it's essential to assess the situation. Labour needs to consider various factors, including the following:

1) Object Characteristics: Evaluate the weight, size, and shape of the object. Determine if it can be lifted safely or requires assistance.

2) Hazards: Identify potential hazards in the environment, such as obstacles or slippery surfaces, which could affect the handling process.

3) Work Area: Ensure the pathway is clear and free from obstructions to facilitate safe movement while carrying the object.

4) Team Collaboration: If the load is too heavy or awkward for one person, plan for teamwork. Communicate clearly with team members to synchronise efforts.

5) Lifting Techniques: Decide on the appropriate lifting technique based on the object's characteristics and your own capabilities.

6) Equipment Utilisation: Determine if Manual Handling Equipment like trolleys or hoists is necessary and ensure its availability and proper functioning.

7) Ergonomics: Consider the Ergonomics of the task. Ask questions like – Are there ways to optimise the process to reduce strain and stress on the body?

Planning allows you to make informed decisions and select the most suitable approach for Manual Handling. It helps prevent unnecessary risks and ensures that the task is executed efficiently and safely. Taking the time to assess the task and plan accordingly can significantly reduce the likelihood of injuries and add to a safer work environment.

Position

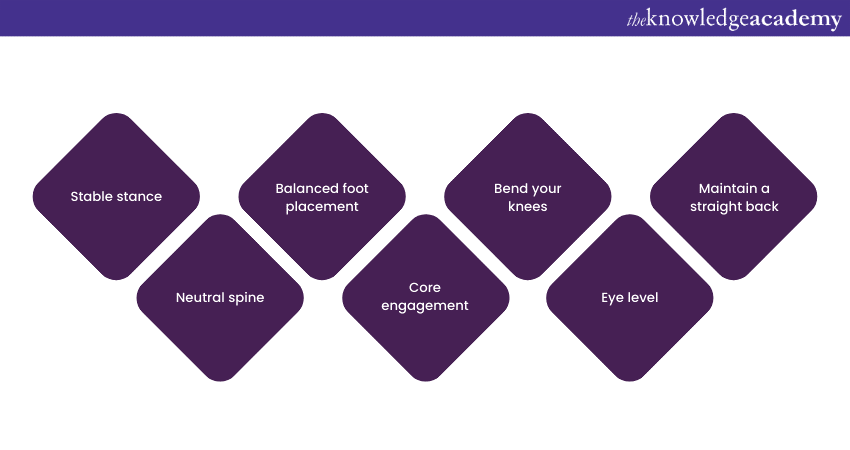

The Position is the second most important of the 5 Key Principles of Manual Handling. Proper positioning is essential to ensure stability and minimise strain during Manual Handling tasks. Let’s explore some useful tips for proper positioning:

1) Stable Stance: Stand with your feet shoulder-width apart to establish a solid and balanced base.

2) Balanced Foot Placement: Position one foot slightly in front of the other, distributing your weight evenly.

3) Bend your Knees: Bend your knees to lower your centre of gravity, enhancing your stability and control.

4) Maintain a Straight Back: Keep your back straight with its natural curves intact, promoting proper alignment.

5) Neutral Spine: Align your head with your spine by tucking in your chin, preventing strain on your neck.

6) Core Engagement: Tighten your core muscles to provide additional support to your spine and lower back.

7) Eye Level: Keep your head level, maintaining an eye level that allows you to see your path clearly.

Proper positioning forms the basis for safe lifting and carrying. It ensures that your body is well-prepared to handle the load while minimising the risk of injuries. By adopting the correct position, you create a strong foundation that enables you to execute the subsequent steps of Manual Handling with greater ease and safety.

Elevate your understanding of Fire Safety principles and practices today with our Fire Safety Training – Sign up now!

Pick

The process of picking up an object demands proper technique to prevent strain and injury. Following these guidelines is essential to ensure that you execute this step safely and efficiently:

1) Secure Grip: Before lifting, make sure to establish a firm and secure grip on the object. This grip enhances your control over the load, reducing the likelihood of accidents.

2) Designated Handles: Whenever possible, utilise designated handles or gripping points on the object. These points are strategically positioned for safe and effective lifting, reducing the risk of slipping or dropping the load.

3) Core Activation: Engage your core muscles before you start lifting. This activation provides stability to your spine and lower back. As a result, it minimises the strain on these areas during the lifting motion.

4) Use Your Legs: Rather than relying solely on your back, engage the strength of your legs to initiate the lifting motion. By bending your knees and employing your leg muscles, you distribute the load more evenly and reduce strain on your back.

5) Keep it Close: When lifting, maintain the object as close to your body as possible. This proximity minimises the leverage the load has on your muscles and provides better control over the lifting motion.

6) Avoid Twisting: One crucial point to remember is to avoid twisting your body while lifting. If you need to change direction, pivot your feet instead. Twisting during lifting can strain your back and lead to injuries.

7) Smooth Motion: As you lift the object, do so smoothly and gradually. Sudden jerks or quick movements can strain your muscles and potentially lead to accidents or discomfort.

Mastering the art of effective picking technique is pivotal for maintaining your body's integrity and preventing injuries during Manual Handling tasks. By adhering to these principles, you not only reduce the risk of strain and discomfort but also establish a foundation for successful Manual Handling.

Master the art of safe Manual Handling techniques with our Manual Handling At Work Training – Sign up now!

Proceed

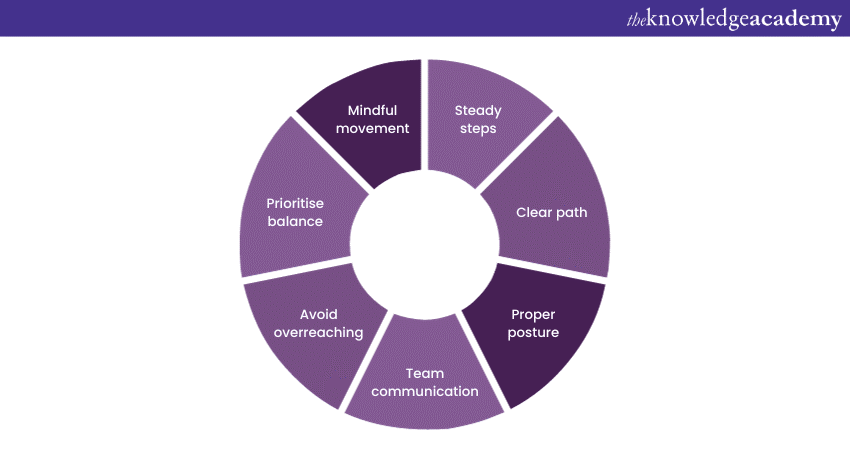

After successfully picking up the load, the way you proceed with it greatly influences your safety and the preservation of the load. Follow these tips to proceed with the load in a secure manner:

1) Mindful Movement: As you move with the load, stay mindful of your surroundings. Be aware of obstacles, uneven surfaces, or any potential Manual Handling Hazards in your path.

2) Steady Steps: Take steady and controlled steps while carrying the load. Avoid sudden movements or jerks that could upset your balance and strain your muscles.

3) Clear Path: Ensure your path is clear of obstacles and obstructions. Maintain a clear line of sight to avoid unexpected collisions or tripping hazards.

4) Proper Posture: Maintain proper posture while moving. Keep your back straight, shoulders relaxed, and the load close to your body to distribute the weight evenly.

5) Avoid Overreaching: Resist the temptation to overreach while carrying the load. Overreaching can strain your muscles and compromise your balance.

6) Team Communication: If you're working with a team, maintain clear communication. Coordinate your movements and actions to ensure a smooth and synchronised carrying process.

7) Prioritise Balance: Focus on maintaining balance throughout the movement. If the load shifts or becomes unbalanced, adjust your position carefully to restore stability.

Proceeding with the load requires careful attention to detail and a keen awareness of your body and surroundings. By following these principles, you reduce the risk of accidents, injuries, and strain during Manual Handling tasks.

Place

The final of the 5 Key Principles of Manual Handling involves placing the load down safely and with precision. Follow these tips to ensure a controlled and secure placement:

1) Bend Your Knees: As you lower the load, bend your knees at the same time and keep your back straight. This technique reduces strain on your lower back.

2) Controlled Descent: Lower the load in a controlled manner, avoiding sudden drops. Gradual descent minimises the impact on your muscles and joints.

3) Release Grip Gently: Once the load is at the desired location, release your grip gently. Avoid sudden or forceful release, which could lead to loss of control.

4) Stable Surface: Choose a stable surface for placing the load. Ensure it's free from obstacles or hazards that could affect the placement process.

5) Avoid Leaning: Refrain from leaning forward while placing the load. Maintain an upright posture to prevent strain on your back and ensure balance.

6) Use Your Legs: Similar to the lifting phase, engage your leg muscles to support the placement. Bend your knees slightly to lower the load smoothly.

7) Secure the Load: After placing the load, ensure it's stable and won't roll or shift unexpectedly. This prevents accidents or injuries once the load is in position.

By adhering to these principles during the placement phase, you complete the Manual Handling process with care and consideration. Remember, the successful execution of each principle contributes to overall safety and promotes a culture of responsible Manual Handling.

Join our Food Hygiene and Safety Training and learn how to analyse all potential food hazards or anything that might hurt the consumer.

Conclusion

We hope you read and understand the 5 Key Principles of Manual Handling. Incorporating these principles into your practices is paramount. Prioritising proper posture, techniques, variation, and education fosters safety, preventing injuries and cultivating a secure and productive work environment.

Elevate workplace safety with our courses on Health & Safety in the Workplace Courses – Join now for a secure and compliant working environment!

Frequently Asked Questions

a) Lifting boxes or heavy equipment.

b) Carrying bags, tools, or items.

c) Pushing or pulling trolleys or carts.

d) Packing or unpacking goods.

e) Leaning over for tasks like scanning groceries or washing dishes.

These activities involve using your hands or body to move or support loads.

Avoid bending your back, twisting your body, or making sudden movements. Don’t lift loads that are too heavy or awkward. Ensure the path is clear and avoid rushing. Use proper tools like trolleys when needed. Poor posture and lack of preparation increase the risk of injury.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Health & Safety in the Workplace, including Health and Safety in the Workplace Training, Advanced First Aid Training and Working at height training. These courses cater to different skill levels, providing comprehensive insights into Workplace Health and Safety.

Our Health & Safety Blogs cover a range of topics offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Health & Safety skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

Manual Handling at Work

Manual Handling at Work

Fri 24th Jan 2025

Fri 28th Mar 2025

Fri 23rd May 2025

Fri 25th Jul 2025

Fri 26th Sep 2025

Fri 28th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please