We may not have the course you’re looking for. If you enquire or give us a call on +34 932716793 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Many organisations across industries find it challenging to maintain the efficiency and reliability of their physical assets. Taking into consideration, the depreciation of tangible assets in a business there are several breakdowns, increased maintenance costs, and unpredictable downtimes which can severally disrupt operations and subsequently hinder growth. In order to cater to such a challenge, a system which monitors asset performance needs to be established and maintained.

Asset Performance Management (APM) makes this possible by optimising asset reliability, extending lifespan, and reducing operational costs. Read this blog to explore what APM is and how it can help your company achieve operational excellence and sustainable growth.

Table of Contents

1) What is Asset Performance Management (APM)?

2) How to build an effective APM program

3) Who utilises Asset Performance Management (APM)?

4) Steps involved in Asset Performance Management?

5) Benefits of Asset Performance management

6) Key differences between ALM and APM

7) Conclusion

What is Asset Performance Management?

APM encompasses strategies, processes, and technologies aimed at maximising the performance and reliability of physical assets throughout their lifecycle. It involves a holistic approach that integrates maintenance, reliability, risk management, and operational excellence to ensure assets operate optimally, minimise downtime, and consistently deliver value.

How to build an effective APM program

APM programs need a strategic blend of people, processes, and technology. It helps define asset criticality to implement various predictive maintenance strategies. They should use Data Analytics and nurture a culture of continuous improvement to drive sustainable Asset Performance and operational excellence.

Elevate your career with our Performance Management Training – register today!

Who utilises Asset Performance Management (APM)?

Asset Performance Management is used in various industries, including manufacturing, energy, utilities, transportation, and more. Organisations of all sizes, from small enterprises to multinational companies, use APM to enhance asset reliability. They optimise maintenance strategies and mitigate risks to achieve operational excellence and maximise return on assets.

Steps involved in Asset Performance Management (APM)?

Asset Performance Management contains several key steps, including asset identification, performance monitoring, condition assessment, predictive analytics, maintenance optimisation, and performance measurement. By systematically managing assets throughout their lifecycle, organisations can optimise Asset Performance, minimise downtime, and extend asset lifespan while maximising return on investment.

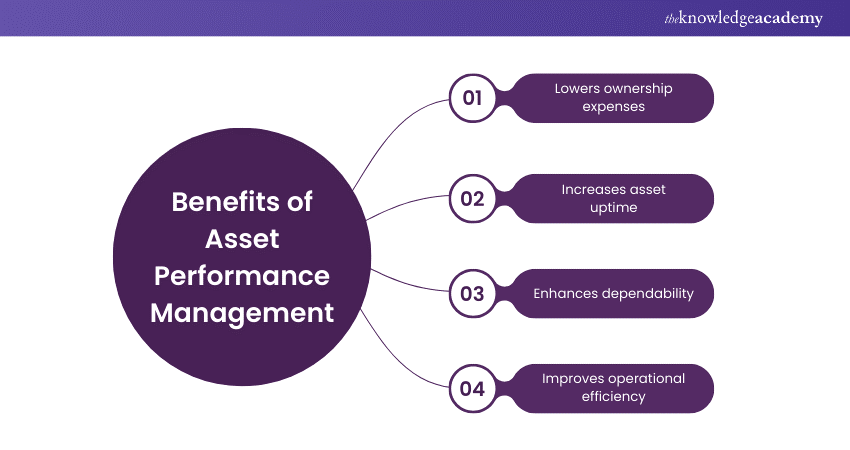

Benefits of Asset Performance Management

APM offers several advantages for organisations across diverse industries. Let's delve into some of the key benefits:

1) Lowers ownership expenses

Businesses can implement various maintenance strategies and use predictive analytics to optimise their maintenance schedules. This approach reduces unexpected breakdowns and repairs, leading to reduced maintenance costs and lower total ownership expenses over the asset's lifecycle.

2) Increases asset uptime

APM improves asset reliability and availability. Its continuously monitoring, timely maintenance, and predictive analytics feature ensures that assets operate at peak performance levels. This increases uptime and minimising unplanned downtime. APM also help improve productivity and revenue generation for organisations.

3) Enhances dependability

Reliable assets are important for maintaining smooth operations and meeting customer demands. APM help enterprises to enhance asset reliability and performance consistency. It identifies potential issues before they escalate and nurture a culture of dependability. APM also ensure that assets operate well and meet production targets.

4) Improves operational efficiency

Efficient Asset Performance directly impacts overall operational efficiency. It optimises maintenance practices, streamlines workflows, and eliminates bottlenecks. This leads to improved resource utilisation and reduced waste. As APM maximises asset productivity and reduce downtime, it enhances operational efficiency and business success.

Learn the key to achieve excellence in every aspect with our Senior Management Training

Key differences between ALM and APM

Asset Lifecycle Management (ALM) and Asset Performance Management (APM) revolve around managing assets. However, they serve different purposes and focus on diverse aspects of Asset Management. Here's a breakdown of the key differences between ALM and APM:

|

Aspects |

Asset Lifecycle Management (ALM) |

Asset Performance Management (APM) |

|

Scope and Focus |

Includes the entire lifecycle of an asset, from acquisition to disposal. Involves activities such as planning, procurement, installation, operation, maintenance, and decommissioning. |

Focuses on optimising asset performance throughout its operational lifespan. Includes maintenance, reliability, and performance optimisation to ensure assets operate at peak efficiency and deliver maximum value. |

|

Time horizon |

Operates on a long-term perspective, considering the entire lifecycle of assets, which can span several years or even decades. |

Typically operates on a shorter time horizon, focusing on optimising asset performance in real-time or over shorter intervals to maximise uptime and productivity. |

|

Objectives |

Manages assets effectively throughout their lifecycle to maximise their value, minimise costs, and ensure compliance with regulations. |

Enhances asset reliability, availability, and performance by implementing proactive maintenance strategies, predictive analytics, and continuous monitoring. Helps minimise downtime, improve operational efficiency, and drive overall business performance. |

|

Approach |

Considers various factors, like asset planning, acquisition, utilisation, maintenance, and disposal, to ensure assets meet organisational objectives and regulatory requirements. |

Adopts a more focused approach, emphasising strategies and technologies specifically aimed at optimising asset performance, enhancing reliability, and maximising operational efficiency. |

|

Tools and Technologies |

Utilises tools and technologies for asset planning, tracking, maintenance management, lifecycle costing, and compliance management. |

Leverages advanced analytics, condition monitoring systems, predictive maintenance software, and IoT sensors to monitor asset health, predict failures, and optimise maintenance schedules for improved performance and reliability. |

ALM is a comprehensive framework for managing assets throughout their lifecycle. At the same time, APM maximises asset performance and reliability to drive operational excellence and business success. Understanding the difference between ALM and APM is important for businesses to develop the right strategies that effectively manage their assets and meet their goals.

Conclusion

APM is an important approach that can improve efficiency and reliability of an organisation. It helps them achieve the full potential of their assets using the power of data, technology, and expertise. So, what are you waiting for? Embrace Asset Performance Management today to propel your operations towards excellence and take your business to the next level.

Unleash your team's full potential with our Introduction to Managing People Training - join us now

Frequently Asked Questions

Measuring Asset Performance is important for identifying inefficiencies. This prevents unexpected breakdowns and optimises maintenance schedules. It helps maximise asset uptime, extend asset lifespan, and reduce operational costs. This helps businesses improve productivity and profitability.

Measuring Asset Performance is important for identifying inefficiencies. This prevents unexpected breakdowns and optimises maintenance schedules. It helps maximise asset uptime, extend asset lifespan, and reduce operational costs. This helps businesses improve productivity and profitability.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Management Courses, including the Performance Management Training, Business Process Improvement Training, and Productivity and Time Management Training. These courses cater to different skill levels, providing comprehensive insights into Transformational Leadership.

Our Business Skills Blogs cover a range of topics related to Performance Management, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Business skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Skills Resources Batches & Dates

Date

Introduction to Supplier Management

Introduction to Supplier Management

Fri 15th Nov 2024

Fri 21st Feb 2025

Fri 25th Apr 2025

Fri 20th Jun 2025

Fri 15th Aug 2025

Fri 17th Oct 2025

Fri 19th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please