We may not have the course you’re looking for. If you enquire or give us a call on +33 805638382 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Ever feel stuck in a cycle of fixing the same problems in your business processes? Are you looking for ways to continually improve and achieve operational excellence? If so, you're not alone. Businesses across industries constantly strive for efficiency and quality. Enter PDCA and DMAIC, two powerful methodologies designed to streamline processes and drive positive change. But between PDCA vs DMAIC, which one should you pick?

Plan-Do-Check-Act (PDCA) and Define-Measure-Analyse-Improve-Control (DMAIC) are cornerstones of Continuous Improvement. While they share a common goal, PDCA and DMAIC differ in their approaches. Understanding these differences is key to selecting the right method for your specific needs. This detailed comparison will unveil the strengths of PDCA vs DMAIC, equipping you to make informed decisions and elevate your business to new heights.

Table of Contents

1) What is PDCA?

2) What is DMAIC?

3) Difference Between PDCA and DMAIC

4) Similarities Between PDCA and DMAIC

5) Conclusion

What is PDCA?

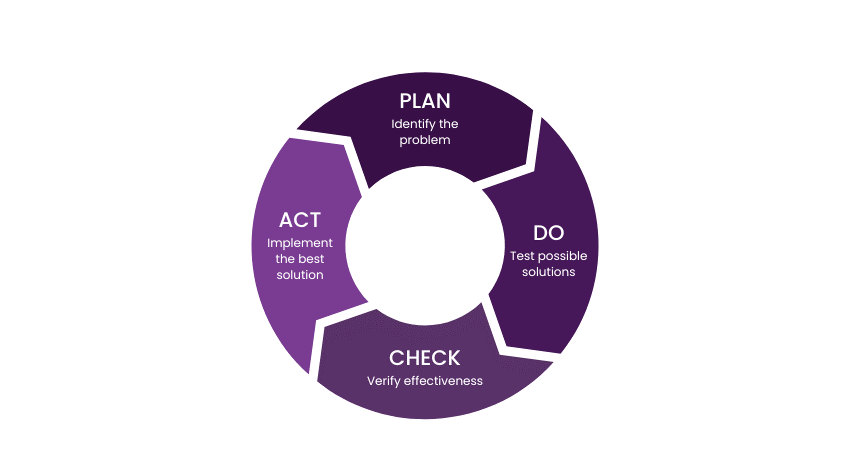

What is PDCA, also known as the Shewhart Cycle or Deming Cycle, is a management methodology used for Continuous Improvement in business processes. It consists of four phases:

a) Plan: Identify and analyse the problem or opportunity, develop hypotheses about what the issues may be, and devise an action plan to address them. This phase involves setting objectives and determining the necessary steps and resources.

b) Do: Implement the action plan on a small scale to test its effectiveness. This phase involves executing the planned actions, collecting data, and documenting any problems or unexpected observations.

c) Check (Control): Monitor and evaluate the results of the implementation against the objectives set in the Plan phase. Analyse the data to determine if the hypothesis was correct and if the plan is working as intended.

d) Act: Based on the evaluation, take corrective actions if necessary. If the plan was successful, implement it on a larger scale. This phase also involves standardising the successful processes and preparing for the next cycle.

The PDCA Cycle fosters Continuous Improvement and helps organisations enhance efficiency and effectiveness.

Advantages of PDCA

The real advantage of the PDCA methodology lies in its simplicity, scalability, and repeatability. This cyclical strategy focuses on defining and addressing one problem at a time with live-tested solutions, making it ideal for Continuous Improvement. Small companies or new business leaders can effectively use PDCA to make consistent progress toward more efficient and effective operations. Its iterative nature ensures that improvements are constantly evaluated and refined, leading to sustained operational excellence.

Disadvantages of PDCA

One common criticism of DMAIC is its ineffectiveness in communication frameworks, often leaving audiences confused and frustrated. Additionally, its one-size-fits-all approach doesn't suit organisations that rely on creativity. When goals are implemented in specific new call monitoring systems, DMAIC may not function appropriately.

What is DMAIC?

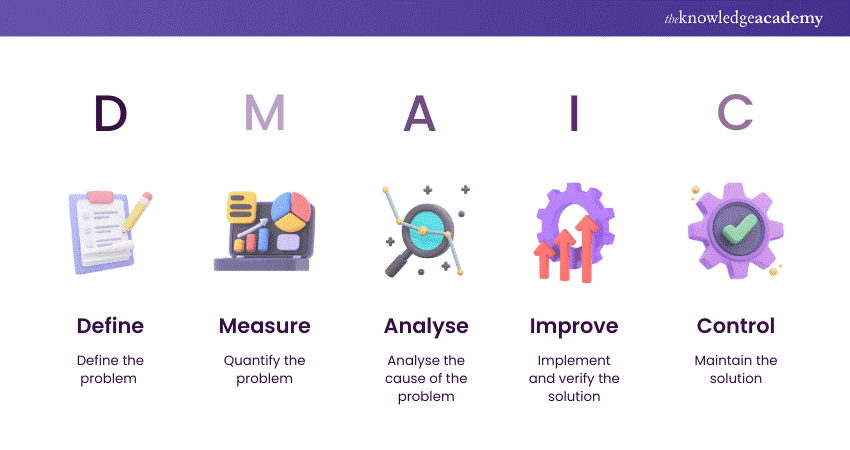

DMAIC is a data-driven improvement cycle used for enhancing, optimising, and stabilising business processes and designs. It stands for Define, Measure, Analyse, Improve, and Control.

a) Define: Identify the problem or improvement opportunity, establish project goals, and define customer requirements.

b) Measure: Collect data and establish baseline measurements to quantify the problem. This phase involves determining key metrics and measuring current performance.

c) Analyse: Examine the data to identify root causes of the problem. Use statistical analysis to pinpoint areas of waste or inefficiency.

d) Improve: Develop and implement solutions to address the root causes. Test the solutions on a small scale, then refine and implement them more broadly.

e) Control: Establish controls to sustain the improvements. Monitor the process to ensure continued performance and make adjustments as necessary.

DMAIC is integral to Six Sigma methodology, focusing on process improvement and variation reduction, ultimately leading to higher quality and efficiency in operations.

Advantages of DMAIC

As the foundation of the Six Sigma process, adopting DMAIC is a significant undertaking that can yield substantial gains when implemented effectively. The "Measure" and "Analyse" stages provide leaders with precise, relevant data about their operations, offering invaluable insights. The "Improve" and "Control" stages allow for extensive deliberation and refinement.

Leaders benefit from seeking diverse perspectives, engaging in meaningful discussions, and welcoming constructive criticism. Information is vital in lean management, and fresh ideas drive Continuous Improvement.

Disadvantages of DMAIC

An unspecific definition can lead to incorrect use of the PDCA cycle. Changes need to be planned over a longer period, and the cycle requires consideration of every aspect, often lacking proactivity. It is an ineffective tool for solving urgent problems due to its multiple steps involving analysis and testing before achieving the final outcome.

Unlock process improvement mastery with our DMAIC Training – Join today and transform your skills!

Difference Between PDCA and DMAIC

Here are the differences Between PDCA and DMAIC:

|

Criteria |

PDCA |

DMAIC |

|

Methodology |

4-step model (Plan-Do-Check-Act) |

5-step model (Define-Measure-Analyse-Improve-Control) |

|

Complexity |

Simple and straightforward |

Detailed and structured |

|

Principles |

Lean principles |

Six Sigma principles |

|

Problem Scope |

Suitable for straightforward problems |

Ideal for complex challenges |

|

Effectiveness |

Best for Continuous Improvement |

Effective for major process enhancements |

|

Application |

Quantitative and qualitative methods |

Detailed planning with thorough data analysis |

1) Methodology and Approach

The PDCA cycle, also known as the Plan-Do-Check-Act cycle, is a repetitive four-step model designed for Continuous Improvement in business processes. It encourages iterative testing and refinement, making it a straightforward approach for achieving incremental enhancements in operations.

DMAIC stands for Define, Measure, Analyse, Improve, and Control. It is a data-driven improvement methodology within Six Sigma, aimed at improving, enhancing, and stabilising business processes through a more detailed and structured five-step approach.

2) Complexity and Detail

PDCA is much simpler and more straightforward compared to DMAIC. Its primary strength lies in its simplicity, making it accessible and easy to implement for organisations looking for a quick and effective way to drive Continuous Improvement without extensive training.

DMAIC, on the other hand, is more detailed and conceptually rigorous. It is a comprehensive approach that involves meticulous planning, data analysis, and process control, making it suitable for organisations seeking to address complex and deep-rooted issues with a structured methodology.

3) Underlying Principles

The PDCA cycle operates on lean principles, focusing on eliminating waste and improving efficiency through four major steps: Plan, Do, Check, and Act. It is designed to solve the majority of business problems effectively by continuously iterating on processes.

DMAIC is grounded in Six Sigma principles, which aim to reduce variability and defects in processes. It consists of five steps: Define, Measure, Analyse, Improve, and Control, each involving detailed analysis and planning to achieve significant process improvements and stability.

Elevate your expertise and ensure compliance with our ISO 17020 Foundation Training – Join today to master the essentials of inspection body standards!

4) Problem-Solving Scope

PDCA is excellent for addressing a wide range of problems, particularly those that are straightforward and do not require extensive data analysis. Its iterative nature allows for ongoing improvements and adjustments, making it highly effective for incremental problem-solving.

DMAIC is particularly effective for tackling larger, more complex challenges. Its structured approach ensures thorough analysis and detailed planning, making it well-suited for resolving issues that require deep investigation and significant process changes.

5) Comparative Effectiveness

While PDCA is highly effective for Continuous Improvement, it may be considered inferior when dealing with more complex and significant business challenges. Its simplicity, while a strength, can also be a limitation in such scenarios.

The Six Sigma methodology, encapsulated by DMAIC, is a robust framework for driving substantial improvements in business processes. Its comprehensive nature and reliance on detailed data analysis make it a powerful tool for achieving major enhancements and process stability.

6) Application and Execution

The PDCA cycle employs both quantitative and qualitative methods to achieve improvements. It emphasises testing and refining processes through iterative cycles, which allows for flexibility and adaptability in various business environments.

DMAIC offers a more detailed planning phase and a structured approach to problem-solving. It provides a systematic way to plot out improvements and ensure that changes are based on thorough data analysis and well-defined objectives.

Become a leader in inspection standards with our ISO 17020 Lead Auditor Training – Register now to advance your auditing skills and expertise!

Similarities and Differences between PDCA and DMAIC

Both PDCA and DMAIC are methodologies designed for Continuous Improvement and problem-solving in business processes. They share several similarities:

a) Iterative Process: Both methodologies rely on iterative cycles to drive Continuous Improvement. PDCA cycles through planning, doing, checking, and acting, while DMAIC follows its five-step process to refine and enhance operations.

b) Focus on Improvement: The primary goal of both PDCA and DMAIC is to improve processes and enhance overall efficiency. They both seek to identify problems, implement solutions, and ensure long-term improvements.

c) Data-Driven: Both approaches emphasise the importance of using data to make informed decisions. PDCA involves checking results and acting based on data, while DMAIC is heavily focused on measurement and analysis to identify root causes and drive improvements.

d) Engagement and Training: Both methodologies require the involvement of team members and stakeholders. Training and educating the workforce on these processes are crucial for successful implementation.

e) Application Across Industries: PDCA and DMAIC are versatile and can be applied across various industries and business functions, from manufacturing to services, aiming to enhance quality and efficiency.

Transform your inspection processes with our ISO 17020 Lead Implementer Training – sign up now to lead with confidence!

Conclusion

Overall, PDCA and DMAIC are both valuable methodologies for Business Process Improvement, each with its unique strengths and applications. PDCA is ideal for organisations seeking a simple, iterative approach to Continuous Improvement, while DMAIC is suited for those needing a detailed, data-driven strategy to tackle complex challenges. Understanding the differences between PDCA vs DMAIC allows organisations to choose the most appropriate tool for their specific needs, ensuring effective and efficient process enhancements.

Elevate your inspection standards with our comprehensive ISO 17020 Trainings – Become a certified expert!

Frequently Asked Questions

Which is the Most Difficult Phase of DMAIC?

The Analyse phase is often considered the most difficult in DMAIC because it involves identifying root causes of problems through rigorous data analysis, requiring advanced statistical tools and techniques, and a deep understanding of the process being studied.

When Should we not Apply DMAIC?

Do not apply DMAIC to problems that lack clear definitions or measurable data. It is unsuitable for projects requiring immediate solutions, creative processes without structured data, or issues where the problem-solving framework is already well-established.

How Long Should a DMAIC Project Take?

A DMAIC project typically takes between three to six months, depending on the complexity and scope of the problem, the availability of data, and the resources committed to the project. Timeframes can vary based on these factors.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 3,000 online courses across 490+ locations in 190+ countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are the Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various ISO 17020 Training, including the ISO 17020 Foundation, Lead Auditor and Internal Auditor Course. These courses cater to different skill levels, providing comprehensive insights into ISO 17025 Handbook.

Our Health & Safety Blogs cover a range of topics related to ISO 17020, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Inspection and Compliance skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

ISO 17020 Foundation Training

ISO 17020 Foundation Training

Mon 7th Jul 2025

Mon 8th Sep 2025

Mon 3rd Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please