We may not have the course you’re looking for. If you enquire or give us a call on 800600725 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Working with dangerous substances in the workplace can pose significant risks, including fire and explosions. To safeguard individuals from such hazards, the UK introduced the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR). These regulations aim to protect both employers and self-employed individuals who handle or are exposed to dangerous substances.

Understanding What is DSEAR is important to ensure compliance and maintain a safe work environment. Read this blog to explore how these regulations affect your business. Learn what you can do to diminish risks effectively.

Table of Contents

1) What is DSEAR?

2) What are Dangerous Substances?

3) Types of Activities Fall Within DSEAR

4) What is Needed for DSEAR?

5) When are DSEAR Regulations Applicable?

6) Conclusion

What is DSEAR?

DSEAR aims to protect individuals from the hazards associated with dangerous substances. These hazards include risks such as fire, explosion, and metal corrosion. DSEAR regulations require employers and self-employed individuals to implement measures that ensure workplace safety.

These measures protect both workers and the public from risks associated with dangerous substances.

What are Dangerous Substances?

Dangerous substances are materials present or used in the workplace. It can harm people through fire, explosion, or metal corrosion If not properly managed. These substances are commonly found in many work environments and include items such as solvents, paints, and varnishes. They also encompass flammable gases like liquid petroleum gas (LPG), dust from machining and sanding, food dust, pressurised gases, and corrosive materials.

Types of Activities Fall Within DSEAR

Here are several activities covered under DSEAR:

a) Flammable goods in retail stores

b) Petrochemical sites (both onshore and offshore)

c) Manufacturing, processing, and storage/warehousing of chemicals

d) Use or presence of flammable gases

e) Hot work activities, such as welding and soldering, involving flammable materials

f) Processes that release natural flammable substances

g) Industries handling or storing dust waste

h) Petrol storage intended for use as fuel

Create a healthy and safe workplace with our Healthy Working Environment Training – Register now!

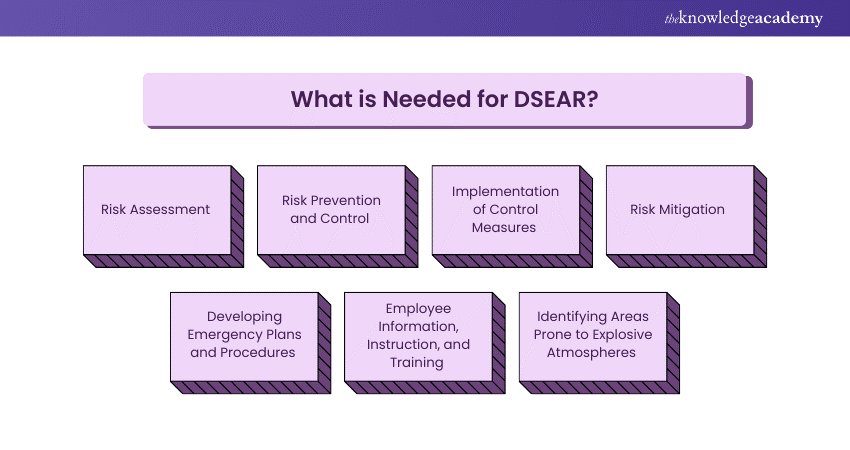

What is Needed for DSEAR?

Employers must require the following:

1) Risk Assessment

Employers should identify all dangerous materials present in their workplace and compare the related risks. This entails knowledge of how these substances may want to potentially motivate damage via hearth, explosion, or corrosion. A thorough risk evaluation enables pinpointing the specific dangers and the likelihood of incidents happening.

2) Risk Prevention and Control

Once the risks are diagnosed, employers should implement measures to dispose of or manage them. This includes substituting dangerous substances with less unsafe ones, enhancing ventilation, or using more secure equipment. If removal isn’t feasible, control measures should be installed in the area to manage the risks efficiently.

3) Implementation of Control Measures

Control measures should be implemented to minimise the effect of any incidents concerning risky substances. This consists of the usage of appropriate storage containers, maintaining equipment, and ensuring proper coping with methods. These measures must be realistic and tailor-made to the particular dangers identified in the workplace.

4) Risk Mitigation

Employers should develop strategies to lessen the severity and impact of potential incidents. This involves installing fire suppression systems, building barriers to contain spills, or imposing procedures to quickly address leaks. The intention is to lessen the outcomes of any accidents related to dangerous substances.

5) Developing Emergency Plans and Procedures

Comprehensive plans and processes need to be created to address injuries, incidents, and emergencies related to risky materials. These plans need to detail the steps to be taken in an emergency. This consists of evacuation routes, emergency contacts, and first aid measures. Ensuring those plans are properly-documented and accessible to all employees is also essential.

6) Employee Information, Instruction, and Training

Employees have to be well informed approximately the dangers related to dangerous substances in the workplace. This consists of providing adequate training on ways to control and manage these risks and how to respond in an emergency. Regular training and clear and effective communication will ensure that employees are prepared to address dangerous substances accurately.

7) Identifying Areas Prone to Explosive Atmospheres

Employers should find and classify areas in the workplace in which explosive atmospheres may additionally occur. This involves assessing the likelihood of explosive mixtures forming and taking steps to prevent fire in these areas. Moreover, using safety equipment and following safety protocols can help avoid injuries in these risky zones.

Be the lifeline in critical moments. Register in our First Aid at Work Training and become a certified hero today!

When are DSEAR Regulations Applicable?

The Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) apply if:

a) Work is being conducted by an employer or a self-employed person.

b) A dangerous substance is present or likely to be present at the workplace.

c) The dangerous substance poses a risk to people’s safety due to fires, explosions, hazardous energetic events, or corrosion of metal. This includes thermal fluids and heat transfer systems.

d) Flammable substances, such as LPG, are being transported.

Boost your workplace safety with our DSEAR Training. Sign up today to mitigate risks, protect employees, and meet legal requirements.

Conclusion

DSEAR ensures workplace safety by addressing risks from dangerous substances. It requires employers to identify hazards, implement control measures, and establish emergency procedures to protect workers and the public. This reduces the likelihood of incidents such as fires or explosions and creates a safer work environment.

Ensure the safety and well-being of your workforce with our Health & Safety in the Workplace Courses – Sign up today!

Frequently Asked Questions

Failure to comply with DSEAR can result in significant legal consequences. This includes fines, prosecution, and potential closure of business operations. Non-compliance also increases the risk of accidents involving fires, explosions, and exposure to hazardous materials, endangering workers and the public.

DSEAR mandates eliminating dangerous substances when possible and using explosion-proof equipment. It also requires proper storage, ventilation, and isolation of ignition sources to ensure safety. These measures aim to minimise risks, protect workers, and prevent accidents or emergencies.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Health & Safety in the Workplace Courses, including DSEAR Training, Fire Marshal Training, and Health and Safety Training for Managers and Supervisors. These courses cater to different skill levels, providing comprehensive insights into the Importance of Safety at Workplace.

Our Health & Safety Blogs cover a range of topics related to Workplace Safety, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your skills in Health & Safety, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

DSEAR Training Course

DSEAR Training Course

Fri 24th Jan 2025

Fri 28th Mar 2025

Fri 23rd May 2025

Fri 25th Jul 2025

Fri 26th Sep 2025

Fri 28th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please