We may not have the course you’re looking for. If you enquire or give us a call on +44 1344 203 999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Heavy loads and aching bones are dreaded companions in bustling workplaces. After all, manual handling tasks are nothing but a game of tug-of-war with gravity. This is where Manual Handling Equipment comes in to save the day. From sturdy trolleys and wheelbarrows to trusty pallet jacks and conveyor belts, these amazing tools make lifting, shifting, and stacking tasks a breeze.

The blog sheds light on the numerous types of Manual Handling Equipment, covering everything from ergonomic tools to personal protective equipment (PPE). So read on, ensure renewed safety in your workplace and embrace smart work over hard work with these powerful tools!

Table of Contents

1) Types of Manual Handling Equipment

a) Lifting and Moving Equipment

b) Material Handling Tools

c) Supportive Equipment

d) Ergonomic Tools

e) Load Securing Tools

f) Drum Handling Equipment

g) Personal Protective Equipment (PPE)

2) What Equipment is Needed for Manual Handling?

3) What is the Equipment List?

4) Conclusion

Types of Manual Handling Equipment

A diverse ensemble of equipment stands as steadfast allies to workers, enhancing their ability to execute tasks with finesse, while safeguarding their well-being. Let's understand the array of these equipment, each playing a distinct role in the choreography of manual tasks.

Lifting and Moving Equipment

At the core of Manual Handling lies the art of lifting and moving objects, often of substantial weight. Here, the prowess of lifting straps emerges, weaving a tale of even weight distribution and reduced strain. A partner, the hand truck or dolly, takes centre stage, allowing the effortless transportation of bulky items. Enter the pallet jack, gracefully manoeuvring heavy loads, and the humble wheelbarrow, embarking on terrains uneven with ease.

a) Lifting Straps: These ingenious adjustable straps are designed to evenly distribute the weight of heavy objects, reducing strain on the back and limbs. Lifting straps facilitate safe and efficient lifting by enhancing grip and control.

b) Hand Trucks/Dollies: A stalwart ally in warehouses and industrial settings, hand trucks or dollies are designed to transport cumbersome items effortlessly. They consist of a flat platform and wheels, enabling workers to manoeuvre loads with minimal physical effort.

c) Pallet Jacks: These mechanical marvels are indispensable for moving heavy pallets and loads within confined spaces. With hydraulic power, pallet jacks elevate loads slightly, making them easier to manoeuvre.

d) Wheelbarrows: A quintessential tool for outdoor tasks, wheelbarrows simplify the transportation of materials across uneven terrains. They feature a single wheel at the front and handles at the back, providing stability and ease of use.

Expand your understanding of Fire Safety principles and practices in our comprehensive Fire Safety Training – Register now!

Material Handling Tools

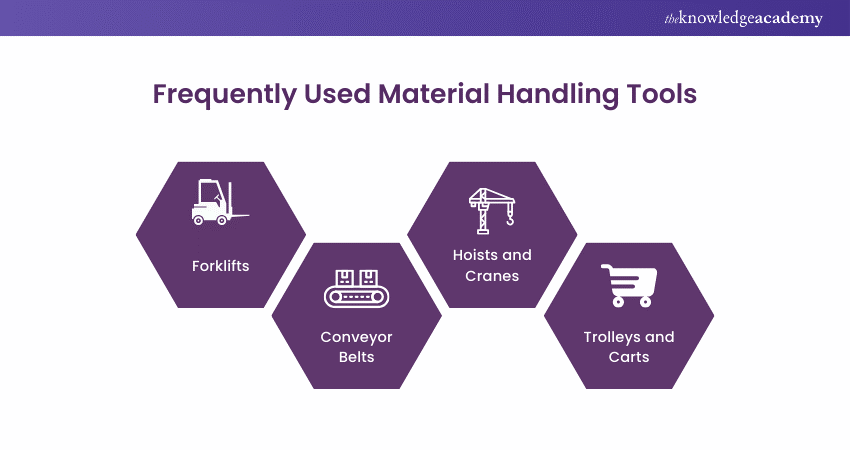

For the monumental task of transferring large and unwieldy loads, the forklift takes charge, its mechanical arms rendering the seemingly impossible, possible. The conveyor belt, a silent conductor of efficiency, guides items along manufacturing and distribution lines, diminishing the demand for manual intervention.

The hoists and cranes, embodying strength and precision, elegantly lift weighty objects to new heights. Trolleys and carts, the unsung heroes, streamline the transportation of numerous items simultaneously. The following are some of the commonly used Manual Handling tools for material handling:

a) Forklifts: The behemoths of material handling, forklifts are equipped with hydraulic arms and forks to lift and move heavy loads with precision. Commonly used in warehouses, construction sites, and distribution centres, Forklifts streamline the movement of goods.

b) Conveyor Belts: In manufacturing and distribution facilities, conveyor belts automate the movement of items along a designated path. This minimises manual lifting and accelerates the production and distribution processes.

c) Hoists and Cranes: These mechanical wonders are designed for vertical lifting of heavy objects, eliminating the need for manual labour. Commonly found in construction and manufacturing, hoists and cranes ensure both safety and efficiency.

d) Trolleys and Carts: Versatile companions for various tasks, trolleys and carts provide a platform for transporting multiple items at once. They come in different sizes and configurations, catering to diverse needs.

Learn how to act in an emergency and analyse and evaluate the risks with our Health And Safety In The Workplace Training.

Supportive Equipment

In the delicate process of Manual Handling, the orchestra of supportive Manual Handling Equipment takes its cue. Back belts, akin to vigilant sentinels, provide lumbar support, preserving posture during the arduous lifting endeavours. Knee pads, allies of the knees, lend their shield against the strain of kneeling.

The anti-fatigue mat, a soft sanctuary underfoot, battles discomfort during prolonged standing, infusing the task with comfort and vigour. Meanwhile, wrist supports choreograph the ballet of repetitive tasks, preserving the harmony of wrist alignment.

a) Back Belts: Back belts, also known as lumbar support belts, provide essential support to the lower back while performing lifting tasks. They assist in maintaining proper posture and reducing the risk of strain.

b) Knee Pads: Ideal for tasks that involve kneeling, knee pads cushion the knees, reducing discomfort and potential injury during activities like floor-level work or gardening.

c) Anti-fatigue Mats: These mats are crafted to alleviate the strain of prolonged standing by offering cushioning and support. Commonly used in industrial settings, they promote comfort and mitigate fatigue.

d) Wrist Supports: Wrist supports are designed to maintain proper wrist alignment during repetitive tasks, such as typing or assembly work. They reduce strain on the wrists and enhance ergonomics.

Learn how to use various accident prevention techniques effectively and efficiently with our Health and Safety Training for Managers And Supervisors Course.

Ergonomic Tools

Ergonomic tools are designed to let the user engage in repetitive motions without undue risk of injury. Ergonomic hand tools might have modified striking heads or plates, padded or specially formed handles, or non-slip coatings on their handles that ensure the workers' firm grip on the tool.

a) Adjustable Workbenches: These workstations can be customised to match the height and preferences of individual workers, promoting ergonomic comfort during various tasks.

b) Ergonomic Handles: Attachments that enhance grip and reduce strain during lifting and pushing activities. They are designed to fit comfortably in the hand, enhancing control and reducing the risk of injury.

c) Tool Balancers: Tool balancers counteract the weight of handheld tools, making them feel lighter and more manageable. This reduces fatigue during tasks that involve frequent tool usage.

d) Lift Tables: Lift tables are versatile platforms that can be adjusted to various heights. They facilitate tasks by positioning items at a comfortable level, eliminating the need for excessive bending or stretching.

Become familiar with various global legal and policy contexts of workplace health with our Healthy Working Environment Training.

Load Securing Tools

Load securing tools emerge as the unsung heroes, entrusted with the crucial task of safeguarding cargo during transit. These tools form an essential bridge between the realms of Manual Handling and efficient transport, ensuring that items arrive at their destination intact and unharmed.

a) Ratchet Straps: Imagine a scenario where a valuable shipment is entrusted to the journey of the open road. Ratchet straps step onto the stage, featuring a mechanism that brings tension to the fore. With precision, they secure cargo with an unyielding grip, embracing crates, pallets, and containers as they embark on their voyage. Through their adjustable prowess, ratchet straps maintain equilibrium, preventing cargo from shifting, sliding, or falling during the tumultuous journey.

b) Cargo Nets: In a world where items come in all shapes and sizes, the role of cargo nets becomes pronounced. These resilient nets envelope irregularly shaped or loosely packed cargo, transforming chaos into order. As vehicles traverse the terrain, cargo nets stand as guardians, preventing items from breaking free and offering a cocoon of protection. Whether it's bricks, bags, or barrels, cargo nets hold an essential place in the art of secure transport.

Learn how to use a Ladder safely and effectively with our Ladder Safety Training Course – Sign up now!

Drum Handling Equipment

In industries where liquids, powders, and chemicals reign supreme, drums stand as the guardians of valuable contents. These tools are tailored to the unique needs of handling barrels, simplifying tasks that would otherwise be arduous and precarious.

a) Drum Dollies: Imagine the challenge of moving heavy barrels from one point to another without compromising safety. Drum dollies emerge as the answer, their design mirroring the gentle embrace of a cradle. With sturdy wheels beneath, they roll gracefully, supporting the weight of barrels and alleviating the strain of manual lifting. Drum dollies transform the complex choreography of barrel transportation into a seamless waltz.

b) Drum Tongs: Within the industrial limits, drums are not merely vessels; they are invaluable repositories of crucial materials. When it comes to lifting and transporting these precious containers, drum tongs come to the rescue. These ingenious tools grip the rim of barrels securely, allowing them to be lifted and moved with precision. Drum tongs embody the fusion of human dexterity and mechanical efficiency, ensuring the safe passage of barrels in a controlled manner.

Gain in-depth knowledge on positive organisational behaviour at work with our Promoting Happiness and Positive Behaviour at Workplace course.

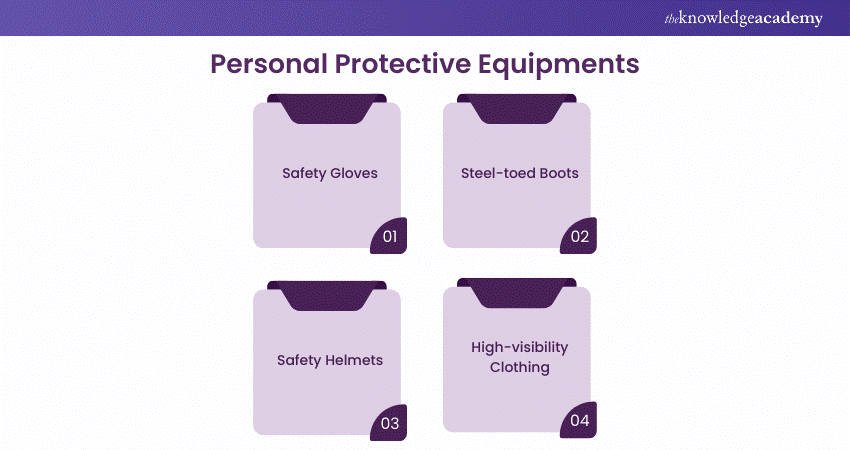

Personal Protective Equipment (PPE)

PPE refers to clothing or equipment such as goggles, gloves, helmets, and steel toe-capped shoes or boots. These are designed to protect the wearer from the risk of injury and infection.

a) Safety Gloves: These protective gloves shield the hands from cuts, abrasions, and potentially hazardous substances. They are a crucial safeguard during Manual Handling tasks.

b) Steel-toed Boots: Designed with reinforced toes, steel-toed boots protect the feet from heavy objects, falling debris, and potential impacts in industrial settings.

c) Safety Helmets: Essential for construction sites and areas with overhead hazards, safety helmets safeguard the head from potential impacts and falling objects.

d) High-visibility Clothing: In low-light conditions or environments with moving machinery, high-visibility clothing enhances worker visibility, reducing the risk of accidents.

What Equipment is Needed for Manual Handling?

There are various equipment for manual handling including wheelbarrows, forklifts, conveyor belts, knee pads, lifting straps, dollies, black belts, cranes

What is the Equipment List?

An equipment list is a document that records, organises, and tracks all the significant equipment information for a project or business. It typically includes details such as the equipment's name, serial number, condition, location, purchase date, and maintenance schedule.

Conclusion

In conclusion, investing in the right Manual Handling Equipment is crucial for promoting worker safety, preventing injuries, and improving overall productivity. By properly utilising lifting and moving equipment, material handling tools, supportive gear, ergonomic aids, and appropriate PPE, businesses can create a safer and more comfortable work environment. Prioritising the well-being of workers through proper equipment contributes to a more successful business.

Learn about a First Aid kit's contents in detail and how to communicate with a casualty with our comprehensive First Aid at Work Course. Join now!

Frequently Asked Questions

Consider factors like the type of load, workplace environment, weight, and frequency of use. For example, pallet jacks are ideal for heavy loads on flat surfaces, while hoists are better suited for vertical lifting.

Regular maintenance is essential to ensure the safety and efficiency of manual handling equipment. This includes lubricating moving parts, checking for wear and tear, inspecting wheels and brakes, and ensuring load capacities are not exceeded. Following manufacturer’s guidelines can extend the lifespan of the equipment.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Health & Safety in the Workplace Courses, including the First Aid at Work Course and the Advanced First Aid Training. These courses cater to different skill levels, providing comprehensive insights into Who is Responsible for Workplace Health and Safety.

Our Health & Safety Blogs cover a range of topics related to manual handling at the workplace, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your manual handling equipment skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

Manual Handling at Work

Manual Handling at Work

Fri 10th Jan 2025

Fri 14th Feb 2025

Fri 11th Apr 2025

Fri 23rd May 2025

Fri 8th Aug 2025

Fri 26th Sep 2025

Fri 21st Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please