We may not have the course you’re looking for. If you enquire or give us a call on +30 2111995372 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Are you eager to streamline your organisation's processes and boost overall efficiency? If so, you've likely come across the powerful methodology known as Lean Six Sigma. In this blog, we will delve into the intricacies of how to implement Lean Six Sigma successfully within your business or project.

Lean Six Sigma marries Lean principles, focusing on waste reduction, with Six Sigma's precision in defect reduction, yielding a potent approach to organisational improvement. It's a methodology proven to deliver remarkable results across industries, irrespective of size or sector. This blog will simplify the Lean Six Sigma journey, offering actionable steps, real-world examples, and valuable insights, equipping you to lead your organisation toward efficiency, growth, and excellence.

Table of Contents

1) Understanding Lean Six Sigma

2) Building a Strong Foundation

3) Define Phase

4) Measure Phase

5) Analyse Phase

6) Improve Phase

7) Control Phase

8) Continuous Improvement

9) Conclusion

Understanding Lean Six Sigma

To effectively implement Lean Six Sigma, it's crucial to grasp the foundational principles that underpin this powerful methodology. At its core, Lean Six Sigma is a data-driven approach aimed at improving processes, eliminating waste, and enhancing overall quality. It blends two distinct philosophies: Lean and Six Sigma.

Lean, inspired by the Toyota Production System, emphasises the identification and elimination of non-value-added activities or waste in processes. These wastes can take many forms, such as unnecessary waiting times, overproduction, excess inventory, or defects. Lean principles aim to optimise process flow, reduce cycle times, and minimise resource utilisation, all with the goal of delivering maximum value to customers.

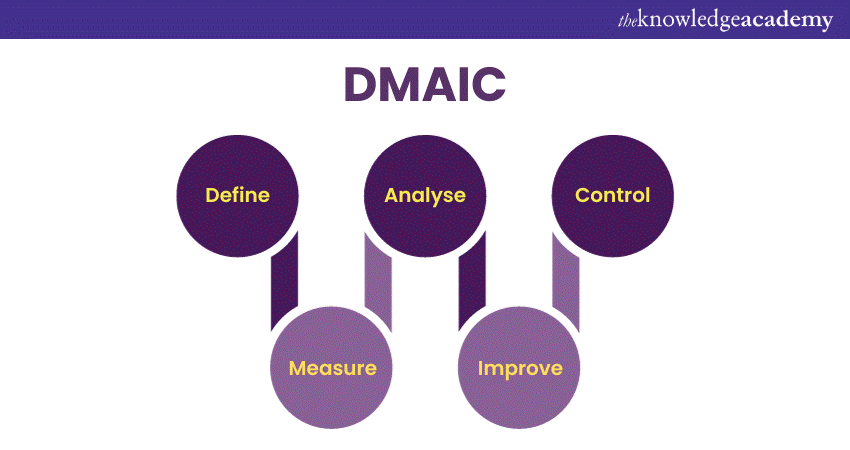

On the other hand, Six Sigma focuses on reducing variation and defects in processes to achieve near-perfect quality. It employs a structured problem-solving methodology, typically characterised by the DMAIC (Define, Measure, Analyse, Improve, Control) or DMADV (Define, Measure, Analyse, Design, Verify) framework. Six Sigma aims to bring processes to a state where they produce fewer than 3.4 defects per million opportunities, resulting in higher customer satisfaction and cost savings.

The synergy between Lean and Six Sigma creates a comprehensive approach that not only eliminates waste but also ensures that the remaining processes are highly efficient and produce consistently high-quality outputs. This understanding serves as the bedrock for successful Lean Six Sigma implementation, guiding organisations towards leaner, more effective operations and a sharper focus on meeting customer needs.

Elevate your skills and drive transformative change with our comprehensive Lean Six Sigma Certification Training.

Building a strong foundation

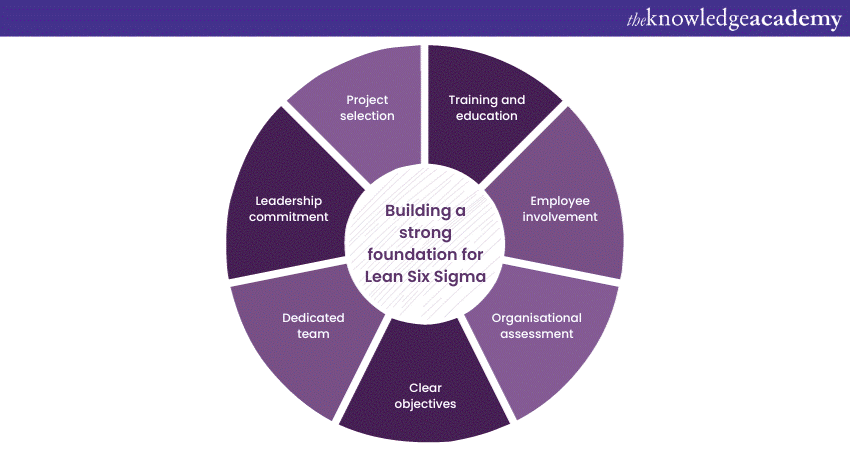

Before embarking on your Lean Six Sigma journey, it's imperative to build a strong foundation that will support the successful implementation of this transformative methodology. This foundation encompasses several key elements, each of which plays a vital role in ensuring your organisation's readiness and commitment to the Lean Six Sigma approach.

1) Leadership commitment: Lean Six Sigma implementation begins at the top. Leaders must not only endorse the initiative but actively participate and champion it. They set the tone for the organisation's commitment to continuous improvement and must align Lean Six Sigma with strategic objectives.

2) Dedicated team: Assemble a dedicated Lean Six Sigma team composed of individuals with diverse skills and expertise. This team will be responsible for driving projects, facilitating change, and ensuring that Lean Six Sigma principles are integrated into the organisation's culture.

3) Clear objectives: Define clear and measurable objectives for your Lean Six Sigma initiative. What specific problems or opportunities do you intend to address? What are your desired outcomes? Having well-defined goals will guide your efforts and help measure progress effectively.

4) Organisational assessment: Assess your organisation's readiness for Lean Six Sigma. This involves evaluating your existing processes, identifying areas that need improvement, and understanding the current culture and mindset within the organisation. Recognising potential challenges early on is essential for effective planning.

5) Employee involvement: Engage employees at all levels. Lean Six Sigma is not a top-down initiative; it thrives when employees at every tier actively participate and contribute their insights. Encourage a culture of openness to change and continuous improvement.

6) Training and education: Invest in Lean Six Sigma training and education for your team. Ensure that they have the necessary skills and tools to navigate the methodology successfully. This training equips team members with problem-solving techniques, statistical analysis methods, and the ability to drive data-driven decisions.

7) Project selection: Carefully select the initial Lean Six Sigma projects. Start with projects that are of moderate complexity and have the potential for significant impact. This approach allows your team to gain experience and build confidence as they progress.

Embark on your Lean Six Sigma Yellow Belt training. Gain essential skills to contribute to process improvements and drive change within your organisation.

Define phase

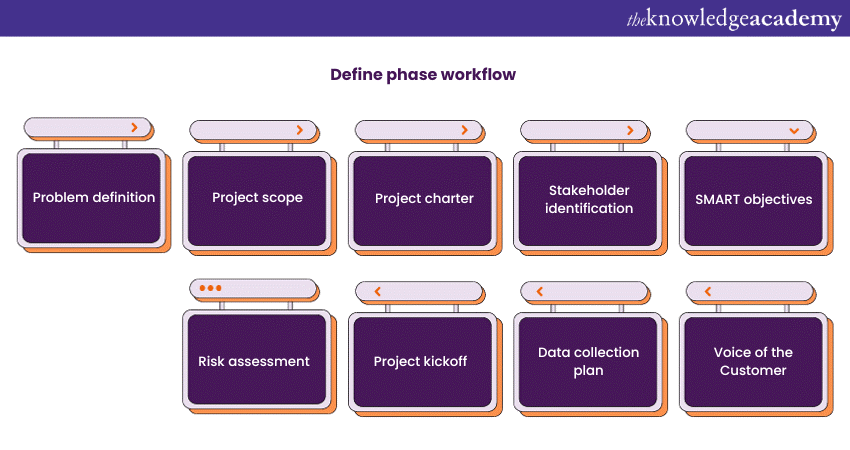

The Define phase is the pivotal starting point in any Lean Six Sigma journey. It serves as the foundation upon which the entire project is built. In this phase, the primary goal is to clearly define the problem, establish project objectives, and ensure alignment with organisational goals.

Here's a detailed overview of the key elements and activities involved in the Define phase:

1) Problem definition: Begin by thoroughly defining the problem you intend to solve. Use specific and measurable terms to describe the issue. Avoid vague or overly broad statements. A well-defined problem sets the stage for focused efforts and accurate measurement.

2) Project scope: Clearly outline the boundaries of your project. What is included, and what is excluded? Defining the scope prevents "scope creep," where the project's objectives expand beyond the original intent. It helps manage expectations and resources effectively.

3) Project charter: Create a project charter, which is a formal document that authorises the project and outlines its objectives, scope, team members, and timeline. It serves as a contract between the project team and organisational leadership, ensuring everyone is on the same page.

4) Stakeholder identification: Identify and engage key stakeholders who have a vested interest in the project's outcome. Stakeholder involvement is essential for gathering input, securing resources, and gaining support throughout the project.

5) SMART objectives: Set Specific, Measurable, Achievable, Relevant, and Time-bound (SMART) objectives for your project. These objectives provide clear targets and criteria for success. SMART objectives ensure that you can measure and track progress effectively.

6) Voice of the Customer (VOC): Gather the Voice of the Customer by collecting feedback, surveys, and input from those directly affected by the problem. Understanding customer needs and expectations is critical for delivering solutions that meet their requirements.

7) Data collection plan: Develop a plan for collecting the necessary data to analyse the problem. Define what data will be collected, how it will be collected, and who will be responsible for data collection. Data-driven decisions are a cornerstone of Lean Six Sigma.

8) Project kickoff: Conduct a project kickoff meeting to introduce the project to the team and stakeholders. Review the project charter, objectives, and expectations. Ensure everyone understands their roles and responsibilities.

9) Risk assessment: Identify potential risks and obstacles that may affect the project's success. Having a risk mitigation plan in place allows for proactive management of issues that may arise during the project.

Measure phase

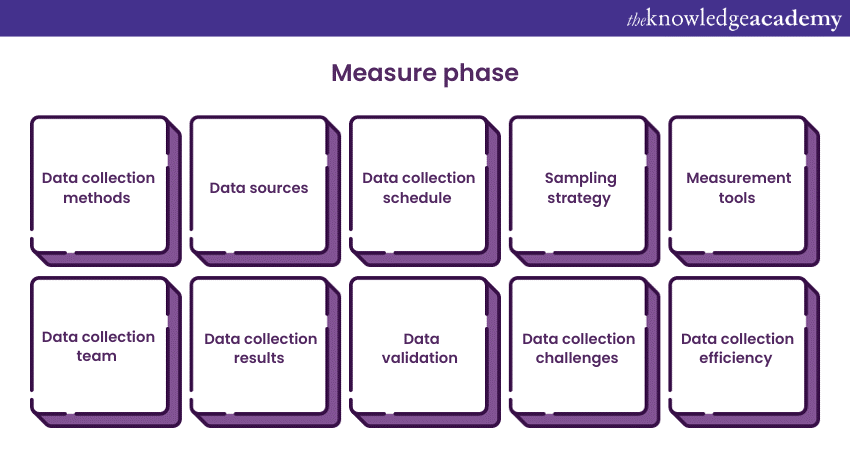

The Measure phase of the Lean Six Sigma methodology is where the project team gathers data, assesses the current state of the processes, and establishes a baseline for future improvements. This phase is crucial for understanding the scope and impact of the identified problem.

Here's a detailed overview of the key elements and activities involved in the Measure phase:

1) Data collection: In this phase, data collection is paramount. The team collects relevant data to quantify the extent of the problem or inefficiency. Data can be sourced from various places, including process records, customer feedback, surveys, and other relevant sources. The data should be accurate, consistent, and representative of the process under investigation.

2) Process mapping: Create detailed process maps to visually represent the current state of the process. Process mapping helps identify bottlenecks, redundancies, and areas where waste occurs. It provides a clear picture of how the process operates.

3) Data analysis tools: Utilise statistical tools and techniques to analyse the collected data. Common tools include histograms, Pareto charts, scatter plots, and process capability analysis. These tools help identify patterns, trends, and variations in the data.

4) Measurement Systems Analysis (MSA): Ensure that your measurement systems are accurate and reliable. MSA assesses the measurement instruments and methods used to collect data. It helps distinguish between genuine process variation and measurement system error.

5) Baseline metrics: Establish baseline performance metrics that reflect the current state of the process. These metrics provide a benchmark against which future improvements can be measured. Metrics may include cycle time, defect rates, or other key performance indicators (KPIs).

6) Process capability: Assess the capability of the current process to meet customer requirements. This involves calculating process capability indices such as Cp, Cpk, Pp, and Ppk. It helps determine how well the process performs relative to its specifications.

7) Root cause analysis: Investigate the root causes of defects or inefficiencies identified during the Measure phase. Tools like the 5 Whys or fishbone diagrams can help uncover the underlying issues contributing to the problem.

8) Data validation: Validate the accuracy and completeness of the collected data. Data validation ensures that the information used for analysis is reliable and free from errors.

9) Documentation: Maintain comprehensive documentation of the data collection process, analysis, and findings. Clear documentation is essential for transparency, communication, and future reference.

Analyse phase

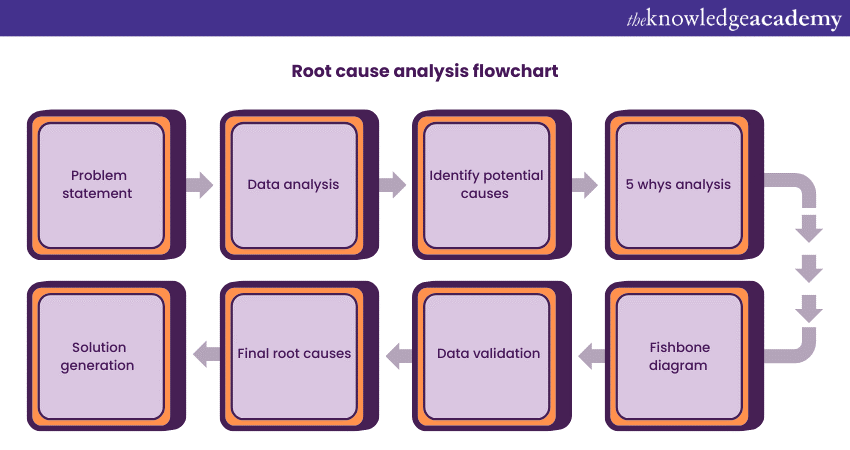

The Analyse phase of the Lean Six Sigma methodology represents a critical juncture in the improvement journey. This phase is dedicated to delving deeper into the data and uncovering the root causes of the identified issues.

Here's a detailed overview of the key elements and activities involved in the Analyse phase:

1) Data analysis: Building on the data collected in the Measure phase, the Analyse phase focuses on in-depth data analysis. Statistical tools and techniques, such as regression analysis, hypothesis testing, and correlation analysis, are applied to identify patterns and relationships within the data. This analysis provides a more comprehensive understanding of the problem.

2) Root cause identification: The primary objective of this phase is to pinpoint the root causes of the issues identified in the Measure phase. The team uses various methods, including the 5 Whys technique, cause-and-effect (fishbone) diagrams, and brainstorming sessions, to systematically explore potential causes. The goal is to identify the underlying factors contributing to the problem.

3) Data validation: Validate the findings to ensure that the identified root causes are indeed responsible for the observed issues. Cross-referencing data and conducting additional tests may be necessary to confirm the accuracy of the analysis.

4) Process flow analysis: Evaluate the current process flow to identify bottlenecks, delays, and areas where waste occurs. Process flow analysis helps visualise the sequence of activities and highlights opportunities for improvement.

5) Failure Mode and Effects Analysis (FMEA): FMEA is a structured approach to assess the impact of potential failures within a process. It helps prioritise identified root causes based on their severity, occurrence frequency, and detectability. This prioritisation guides decision-making on which issues to address first.

6) Solution generation: While the primary focus is on root cause identification, the Analyse phase may also involve generating initial ideas for potential solutions. These solutions serve as a starting point for the subsequent Improve phase.

7) Impact assessment: Estimate the potential impact of addressing the identified root causes. This assessment helps prioritise the most critical issues to tackle, considering factors like cost, resource requirements, and expected benefits.

8) Data visualisation: Utilise data visualisation techniques, such as charts and graphs, to present findings and insights in a clear and compelling manner. Effective data visualisation aids in communication and understanding among team members and stakeholders.

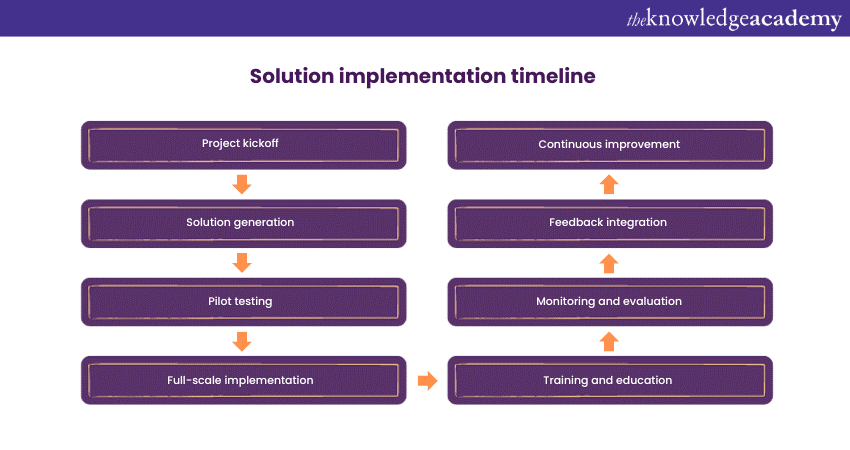

Improve phase

The Improve phase of the Lean Six Sigma methodology is where the rubber meets the road in terms of making tangible improvements to the processes and addressing the root causes identified in the previous phases. This phase is marked by innovation, experimentation, and the pursuit of solutions that will lead to enhanced process performance.

Here's a detailed overview of the key elements and activities involved in the Improve phase:

1) Solution generation: Building on the insights gained during the Analyse phase, the project team generates a range of potential solutions to address the root causes of the identified problems. These solutions can take various forms, from process redesign to technology implementation or changes in operating procedures.

2) Pilot testing: Before implementing solutions on a full scale, it's often advisable to conduct pilot tests or small-scale experiments. Pilot testing allows the team to assess the feasibility and effectiveness of proposed solutions without risking disruption to the entire process. It also provides an opportunity to fine-tune the solutions based on real-world feedback.

3) Lean principles: In the Improve phase, Lean principles play a significant role in streamlining processes and eliminating waste. Techniques such as Value Stream Mapping (VSM) and 5S (Sort, Set in order, Shine, Standardise, Sustain) are commonly applied to optimise workflows.

4) Change management: The implementation of process improvements often involves change, and managing this change effectively is crucial. Change management strategies, including communication plans, training, and stakeholder engagement, ensure that the organisation embraces and supports the proposed changes.

5) Data-driven decision-making: Continue to rely on data-driven decision-making throughout the Improve phase. Regularly monitor key performance indicators (KPIs) to assess the impact of implemented solutions and make adjustments as necessary.

6) Continuous improvement: Embrace the concept of continuous improvement by fostering a culture that encourages ongoing refinement of processes. Teams should be empowered to identify additional opportunities for enhancement and contribute to a culture of innovation.

7) Risk mitigation: Proactively identify and mitigate risks associated with implementing changes. Assess potential challenges and develop contingency plans to address unexpected issues that may arise during the improvement process.

8) Solution validation: Validate the effectiveness of the implemented solutions against the objectives defined in earlier phases. Ensure that the improvements are achieving the desired outcomes, such as reduced defects, shorter cycle times, or cost savings.

9) Documentation: Maintain detailed records of the improvements made, including changes to processes, documentation updates, and results of pilot tests. This documentation serves as a valuable reference for future audits and ensures that knowledge is retained within the organisation.

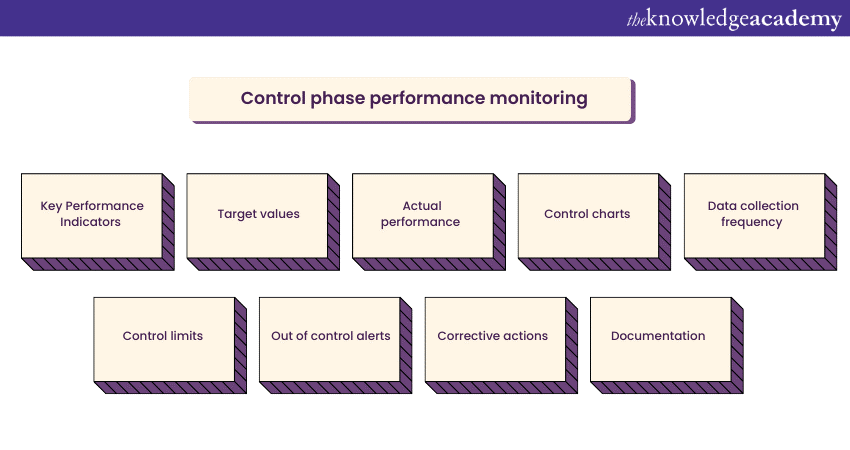

Control phase

The Control phase of Lean Six Sigma is the culmination of a well-structured improvement journey. It's focused on ensuring that the gains achieved through process improvements in the previous phases are sustained over the long term. This phase is about establishing robust processes, monitoring performance, and preventing the recurrence of issues.

Here's a detailed overview of the key elements and activities involved in the Control phase:

1) Standardisation: Implement standardised procedures and work instructions based on the improvements made during the Improve phase. Standardisation ensures consistency and minimises process variations.

2) Control plans: Develop control plans that outline the key parameters, metrics, and checkpoints for the process. Control plans provide a structured framework for ongoing monitoring and management.

3) Key Performance Indicators (KPIs): Identify and define KPIs that align with the objectives of the Lean Six Sigma project. These metrics should be closely linked to the critical factors that affect process performance.

4) Monitoring and measurement: Establish a system for regular monitoring and measurement of the defined KPIs. Data collection and analysis remain crucial in the Control phase to detect any deviations from the improved process.

5) Process ownership: Assign responsibility for the improved process to a designated process owner or team. Having clear ownership ensures accountability for the process's performance and sustainability.

6) Control charts: Utilise control charts and statistical process control (SPC) techniques to visually monitor process stability and detect any signs of variation or instability. Control charts help in distinguishing between common cause and special cause variation.

7) Response plans: Develop response plans for addressing any deviations or unexpected issues that arise during ongoing operations. These plans should outline the actions to be taken when the process moves out of control.

8) Training and knowledge transfer: Continue to train employees and ensure that they are well-versed in the updated processes. Knowledge transfer is vital to maintain the improvements, especially in the event of employee turnover.

9) Documented procedures: Maintain up-to-date documentation of the standardised procedures, control plans, and any changes or updates made to the process. This documentation serves as a reference for employees and future audits.

10) Auditing and reviews: Conduct regular process audits and reviews to assess adherence to the improved processes and control plans. Audits help identify any areas where adjustments or corrective actions may be necessary.

11) Continuous improvement culture: Encourage and foster a culture of continuous improvement within the organisation. Employees should be empowered to suggest enhancements and innovations to further optimise the process.

Continuous improvement

Continuous improvement is at the heart of Lean Six Sigma philosophy. It's not just a phase in the process; it's a cultural mindset that permeates an organisation's DNA. In a world of ever-evolving markets and customer demands, organisations that embrace continuous improvement gain a competitive edge. Here's a closer look at what continuous improvement entails and why it's so critical:

1) Ongoing evaluation: Continuous improvement means consistently assessing your processes, products, and services. It involves regularly seeking feedback from customers, employees, and stakeholders. This evaluation ensures that you remain adaptable and responsive to changing circumstances.

2) Kaizen philosophy: Derived from Japanese management practices, Kaizen embodies the spirit of continuous improvement. It encourages small, incremental changes made by employees at all levels of an organisation. These small improvements, when accumulated over time, result in significant advancements.

3) Data-driven decisions: A commitment to continuous improvement relies on data and facts rather than assumptions. Collecting and analysing data helps identify areas for enhancement and provides insights for making informed decisions.

4) Problem-solving culture: Organisations that prioritise continuous improvement encourage employees to identify problems and suggest solutions. A culture of problem-solving fosters innovation and empowers teams to address issues swiftly.

5) Flexibility and adaptation: Continuous improvement requires organisations to remain agile and adaptable. As markets, technologies, and customer preferences change, organisations must pivot and evolve to stay relevant.

6) Employee engagement: Engaged employees are more likely to contribute ideas and efforts towards improvement. Recognising and rewarding employee contributions to continuous improvement initiatives can drive enthusiasm and participation.

7) Benchmarking and best practices: Regularly benchmarking against industry standards and adopting best practices from other organisations can provide valuable insights and ideas for improvement.

8) Leadership support: Leaders play a pivotal role in fostering a culture of continuous improvement. Their commitment to ongoing enhancement sets the tone for the entire organisation.

9) Lean Six Sigma principles: Lean Six Sigma's DMAIC (Define, Measure, Analyse, Improve, Control) framework provides a structured approach to continuous improvement projects. It emphasises data-driven problem-solving and sustainable change.

Conclusion

In conclusion, implementing Lean Six Sigma, as explained in this comprehensive guide, underscores the significance of clear problem definition, data-driven analysis, and sustainable control mechanisms. By instilling a culture of continuous improvement and committing to the principles of Lean Six Sigma, organisations can not only achieve immediate gains but also ensure their long-term success and competitiveness in an ever-evolving marketplace, truly exemplifying how to implement Lean Six Sigma effectively.

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please