We may not have the course you’re looking for. If you enquire or give us a call on +30 2111995372 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Do you want to revolutionise your business processes and maximise its efficiency? Then Lean Management is the way to go. It’s a powerful strategy aims to achieve operational excellence while delivering value to your customers. It focuses on optimising resources, streamlining workflow and eliminating waste. In this blog, we will learn about Lean Management and its principles. Additionally, you will learn how to use Lean Management tools to benefit your organisation.

Table of Contents

1) What is Lean Management?

2) Five Key Principles of Lean Management

3) Tools of Lean Management

4) Lean Management Advantages

5) Examples of Lean Management

6) Conclusion

What is Lean Management?

Lean Management is a business methodology that focuses on ongoing enhancement. It aims to gradually improve processes to boost efficiency and quality over time.

Lean Management aims to optimise resources and craft a consistent workflow based on actual customer requirements to provide value to the customer. The main goal is to eliminate any time, effort, or money wasted by examining each stage of a business procedure and making changes. This philosophy originated in the field of manufacturing.

Lean Management encourages collaborative leadership and accountability, guaranteeing that all workers participate in the enhancement effort. This management approach is a blueprint for crafting a thriving, adaptable, and constantly growing organisation. It also recognises and addresses actual issues.

Lean Management principles were planted in the Toyota Production System, which was developed in the late 1940s. Toyota used the five principles of Lean Management to eliminate non-value-adding processes and establish what is now recognised as the Toyota Way. By applying these principles, they saw notable efficiency, productivity, cost-effectiveness, and cycle time enhancements.

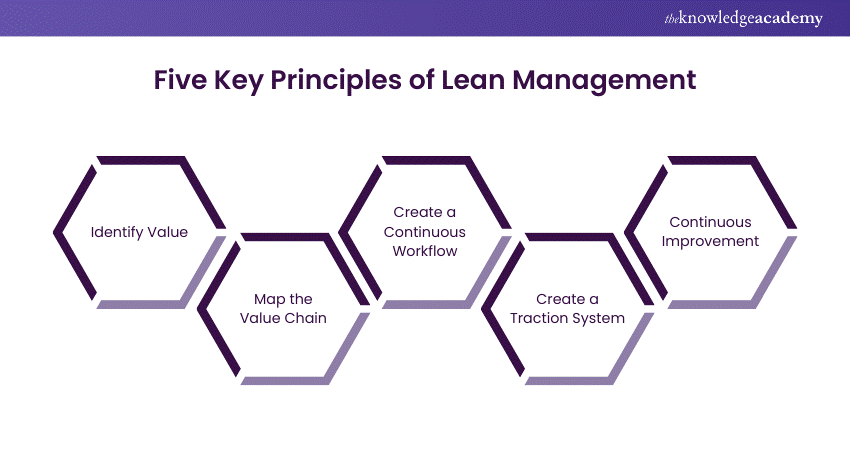

Five Key Principles of Lean Management

To apply Lean Management effectively in your organisation, it is mandatory to follow these five key principles:

1) Identify Value

Every company strives to provide goods or services that customers are willing to purchase, identifying the worth of your offerings as determined by your customers' requirements. The key is to resolve the customer's issue, especially in the part they are ready to pay for. Any task that does not provide benefits is seen as unnecessary. Start by defining the value you aim to deliver.

2) Map the Value Chain

This stage includes outlining the flow of your company's operations, which consists of all tasks and employees responsible for providing the final product to the customer. By analysing the value chain, you can pinpoint steps that do not add value. This procedure aids in defining team duties, making it easier to remove inefficiencies and improve workflow efficiency.

3) Create a Continuous Workflow

Once you grasp the value chain, ensure that every team's workflow is seamless and continuous. This frequently involves dividing tasks into smaller segments and picturing the process to identify and eliminate any barriers. Smooth workflows that reduce bottlenecks and interruptions promote efficient teamwork between departments.

4) Create a Traction System

An efficient workflow enables teams to finish tasks more quickly and with reduced exertion. To maintain this stability, create a pull system where work is generated only as needed. This system improves resource usage by matching production to demand, like a restaurant cooking meal only when requested.

5) Continuous Improvement

Ultimately, the Lean Management system needs continual focus and improvement. Continuous improvement includes getting employees at every level involved in enhancing processes. Regular team gatherings can assist in reviewing advancements, recognising challenges, and implementing minor enhancements.

Boost your Business Improvement skills with our Lean Training- Sign up today!

Tools of Lean Management

Let's look at some of the popular Lean Management tools that organisations use to implement Lean philosophy.

a) Value-Stream Mapping (VSM): It is used for analysing, visualising, and boosting the delivery of products or services.

b) 5 Whys Root Cause Analysis: This method identifies all the causes of process hindrance.

c) Kanban: It is a system that defines, manages, and enhances services to deliver knowledgeable work and assist in visualising the workflow.

d) 5S Method: This technique aims to reduce waste and streamline operations, including 5S: Sort, Sustain, Standardise, Shine, and Set in Order.

e) Gemba Walk: It’s a practice where leaders do the examining of the floor to observe operations personally. The leader also identifies wasteful activities.

f) Andon: It’s an audible alert system that notifies operators of production line issues and provides quick problem-solving responses.

g) Heijunka: This technique is used to level-load production and reduce the unevenness of overburdening processes.

h) Hoshin Kanri: It is a seven-step process for engaging and aligning strategic goals within a company to ensure the main goal is achieved.

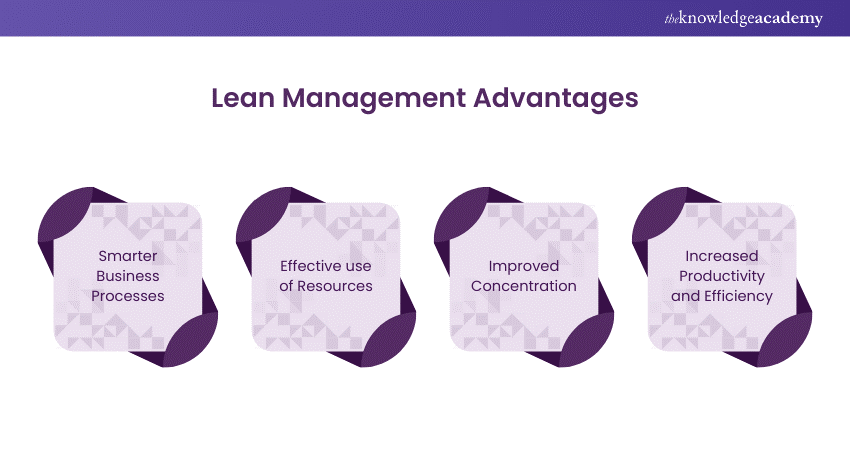

Lean Management Advantages

Lean Management enhances organisations by maximising efficiency in all aspects of the work process throughout the entire company structure. Managers can reap several essential advantages.

a) Smarter Business Processes: The pull system ensures that work is done only in response to actual demand, overcoming overproduction and directing efforts to necessary areas.

b) Effective use of Resources: The pull system also works in accordance with the operations and real customer demand to ensure resources are available when needed. It minimises waste and preserves assets.

c) Improved Concentration: Lean Management minimises unnecessary tasks, allowing employees to work on valuable activities and boosting efficiency.

d) Increased Productivity and Efficiency: The workforce can work more efficiently and effectively by focusing more on activities that provide value.

The Lean Management approach promotes a strong manufacturing setting, significantly improving a company's overall efficiency.

Become a master of Lean Management with our Certified Lean Practitioner Course- Register now!

Examples of Lean Management

Lean Management principles are adaptable and practical in numerous sectors. It's because it provides practical solutions to handle processes. Here are some of the examples:

Lean Software Development

In 2003, Mary and Tom Poppendieck launched their book "Lean Software Development: An Agile Toolkit," which delves into implementing Lean principles in software development. At first, Lean Software Development was slow to catch on, but it has become widely adopted in the industry based on seven fundamental principles.

The Lean Startup

Engineer and entrepreneur Eric Ries created a methodology using Lean principles to help startups succeed. In his 2011 book, "The Lean Startup," he presents five basic principles aimed at enhancing startups' adaptability and responsiveness. This method focuses on reducing product development timelines and rapidly confirming business ideas, benefiting startups, government entities, marketing experts, and others.

Lean Accounting

Lean Accounting utilises Lean Management concepts such as prioritising customer value and minimising waste in financial operations. This method assists organisations in making their operations more efficient, aligning them with strategic objectives, and ensuring financial data is easily accessible and helpful for various teams and departments.

Lean Management Applied in Healthcare

Healthcare industries are increasingly adopting Lean Management principles to improve their services, boost worker satisfaction, and make services cost-effective. This approach also helps streamline processes, enhance patient care and reduce wait times.

Conclusion

We hope that you understand how crucial Lean Management is for your organisation. The approach streamlines operations and cuts out waste. By adopting the principles, you can boost your company's productivity and efficiency, thus improving customer satisfaction and sustaining growth. Apply the Lean Management strategies to optimise operations.

Kickstart your Lean Management journey with our Certified Lean Foundation Course - Join today!

Frequently Asked Questions

Lean Management emphasises removing wastage and streamlining processes. On the other hand, Six Sigma reduce defects through data analysis.

Yes, it’s scalable and can aid small businesses in reducing costs and enhancing customer satisfaction by eradicating waste.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Lean Training , including the Introduction to Lean, Certified Lean Foundation, and Certified Lean Practitioner. These courses cater to different skill levels and provide comprehensive insights into 5 Lean Principles to Enhance Business Efficiency

Our Business Improvement Blogs cover a range of topics related to Business Improvement, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Lean Management skills. The Knowledge Academy's diverse courses and informative blogs have got you covered.

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please