We may not have the course you’re looking for. If you enquire or give us a call on +30 2111995372 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Different industries come with unique Logistical challenges. The pharmaceutical sector often requires cold storage and timely deliveries to ensure medicines remain effective. In contrast, the fashion industry prioritises speed, especially during seasonal launches. Different Types of Logistics play a crucial role in different sectors.

Custom solutions ensure that every business, regardless of size or niche, operates efficiently. As global business gets trickier, we need more ways to move stuff around to keep up. In this blog, we will understand Different Types of Logistics services companies use to manage productivity and efficiency.

Table of Contents

1) Types of Logistics

a) Inbound Logistics

b) Outbound Logistics

c) Reverse Logistics

d) Third-party Logistics (3PL)

e) Fourth-party Logistics (4PL)

f) Distribution Logistics

g) Production Logistics

h) Green Logistics

2) Conclusion

What is Logistics?

Logistics refers to the detailed organisation and implementation of a complex process. It manages the movement of goods from where they are manufactured to where they're used, fulfilling customer or business needs. This includes not only the physical movement of goods but also the planning, warehousing, transportation, inventory management, order fulfilment, and even customer service.

Logistics ensures that resources are acquired, stored, and transported to their destination. It is an intricate dance of coordination, ensuring that products or services are available where and when needed, in the exact quantity and quality required. Effective Logistics can create the difference between success and failure for businesses, affecting every facet of an organisation, from procurement to customer satisfaction.

Master the world of Logistics with our Logistics Management Training now!

Types of Logistics

Logistics not only guarantees the timely delivery of goods but also ensures that resources are available when and where they're needed most. But to think of Logistics as a singular, uniform entity would be an oversimplification. There are various Types of Logistics, each tailored to cater to specific needs, industries, or sectors. This categorisation often depends on factors such as the product's nature and the transportation mode required.

Inbound Logistics

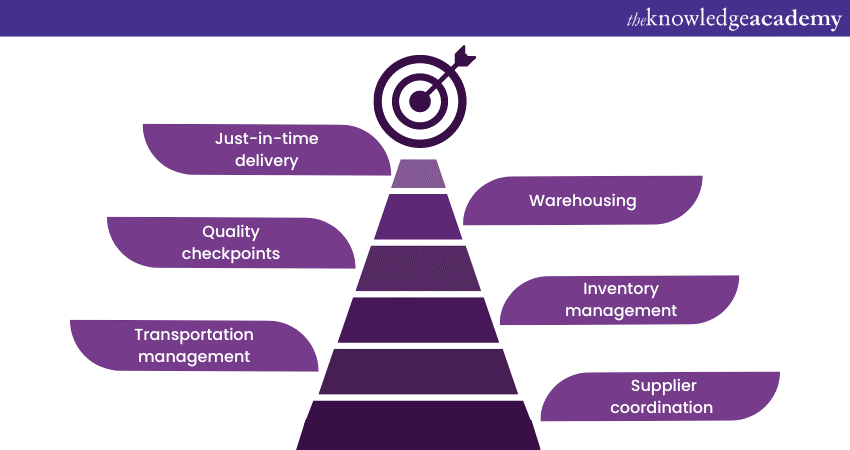

Inbound Logistics manages the flow of raw materials from suppliers to manufacturers, emphasising efficiency, relationships, transportation, inventory, quality, and timely delivery. But this is more than just the physical movement of goods. It's about creating efficiencies to ensure that operations downstream are smooth and cost-effective.

The importance of efficient Inbound Logistics cannot be overstated. Any delay or disruption in receiving necessary materials can halt or slow production, leading to financial losses. Key components of Inbound Logistics include:

a) Supplier coordination: Building strong relationships with Suppliers is vital. Reliable Suppliers ensure the timely delivery of quality goods. Regular communication and collaboration with Suppliers can lead to better forecasting and fewer disruptions.

b) Transportation management: Deciding the most efficient way to transport goods is critical. Should goods be shipped via air, sea, rail, or road? The choice depends on factors like urgency, cost, and volume.

c) Inventory management: While the goal is to reduce inventory levels to cut costs, there's a balance to strike. Too little inventory risks production stoppages, while excess inventory incurs additional storage costs.

d) Quality checkpoints: Before materials are integrated into production, they often undergo quality checks. This ensures the final product maintains the desired quality standards and reduces wastage due to defective materials.

e) Warehousing: Efficient storage systems allow for quick retrieval and minimal handling. An organised warehouse means goods are stored properly, can be easily located, and can be dispatched promptly when needed.

f) Just-in-time delivery: This is an approach where materials are delivered right when they are needed, reducing the need for excessive inventory storage. It requires precise coordination and timing but can lead to significant cost savings.

Dive into industry expertise with our top-tier Industry Training courses!

Outbound Logistics

Outbound Logistics focuses on distributing finished products from manufacturers to end consumers or retailers.

a) Handles final product distribution: Products need efficient systems to reach the intended market or user after manufacturing.

b) Ensures products reach destinations: Efficient distribution ensures products are available at marketplaces, stores, or directly to consumers.

c) Key components: The process incorporates transportation methods, warehousing solutions, and adept inventory management techniques.

d) Packaging is pivotal: Good packaging not only markets the product but also guarantees its safety during transit.

e) Efficient route planning: By planning optimal routes, companies can reduce fuel costs and delivery times.

f) Multiple delivery methods: Depending on the urgency, cost, and destination, products might travel by air, sea, rail, or road.

g) Timely deliveries are crucial: Delivering on time enhances brand reputation, ensuring customer loyalty and trust.

h) Modern tracking aids transparency: Customers value being informed. Modern tracking tools provide real-time shipment updates, enhancing user experience.

Reverse Logistics

Reverse Logistics manages products back from consumers to origin points for various reasons.

a) Beyond traditional Logistics: It's more than returning items; it's about capturing value from returned products.

b) Handling returns: Customers might send back items due to defects or dissatisfaction, necessitating an efficient return system.

c) Eco-friendly approach: Effective reverse Logistics aids in recycling and reusing, promoting sustainability.

d) Repairs central: Defective goods are fixed, refurbished, and potentially reintroduced to the market.

e) Managing surplus: Overstocked items, returned to central points, are redistributed to match demand.

f) Environmental consciousness: Proper disposal or repurposing demonstrates a company's commitment to ecological balance.

g) Asset recovery: By salvaging and repurposing returned items, businesses can recoup costs and reduce waste.

Third-party Logistics (3PL)

Third-party Logistics (3PL) companies offer a variety of outsourced Logistics solutions, enhancing supply chain processes for businesses. They bridge gaps in the Logistics chain, streamlining operations for better efficiency.

a) Outsourcing made efficient: 3PLs expertly manage specific Logistics, letting businesses concentrate on their primary competencies. This partnership enables firms to be more agile, offloading complex Logistics tasks.

b) Diverse services on offer: 3PLs offer a wide range of services, including transportation, warehousing, and efficient inventory oversight. Their versatility ensures that businesses find tailored solutions for varied needs.

c) Adaptable to business needs: Whether small or large, 3PLs provide businesses with scalable, customised Logistic strategies. This adaptability ensures that the supply chain remains uninterrupted and efficient.

d) Cost-effective: Engaging with 3PLs often leads to significant savings, as they bear infrastructure and staffing expenses. Over time, these cost savings can considerably enhance a company's bottom line.

e) Global reach: With expansive international networks, 3PLs facilitate businesses in reaching global markets seamlessly. This expanded reach aids businesses in tapping into new markets and demographics.

f) Technology-driven: 3PLs employ cutting-edge software, ensuring streamlined inventory management and precise shipment tracking. This tech-forward approach reduces errors and improves overall supply chain visibility.

g) Risk management: Leveraging their vast experience, 3PLs adeptly address potential transport, damage, or customs challenges. By foreseeing and mitigating risks, they enhance the reliability of the supply chain.

h) Strategic partnerships: A symbiotic relationship with a 3PL promotes mutual growth, understanding, and long-term collaboration. By aligning goals, both parties benefit from shared successes and innovations.

Transform your ideas into success with our Product Management Training today!

Fourth-party Logistics (4PL)

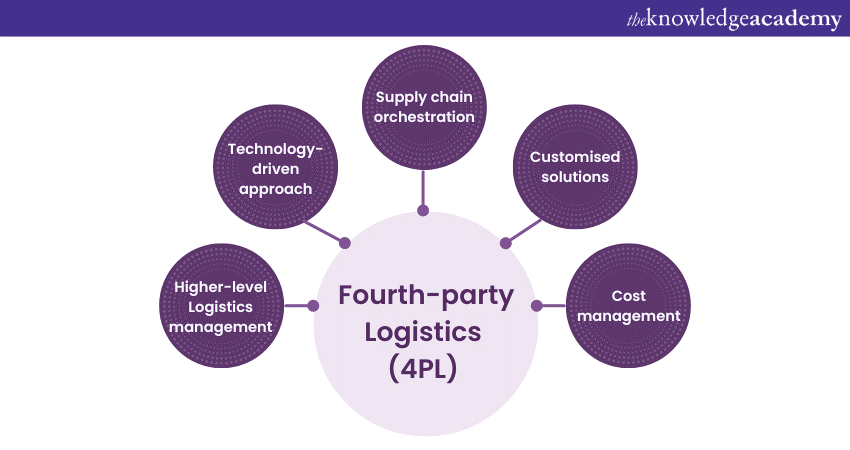

Fourth-party Logistics (4PL) providers operate the entire supply chain, offering an integrated Logistics solution for businesses. Let us have a look at a few objectives that it provides:

a) Higher-level Logistics management: Unlike 3PLs, 4PLs manage the entire Logistics process, integrating resources and technologies.

b) Technology-driven approach: 4PLs harness advanced technologies to provide data-driven insights and end-to-end supply chain visibility.

c) Supply chain orchestration: They coordinate all parties - from suppliers to retailers - ensuring a seamless flow in operations.

d) Customised solutions: 4PLs design bespoke supply chain strategies tailored to specific business needs and goals.

e) Cost management: By optimising operations they help businesses achieve significant savings and better budgetary control.

f) Continuous improvement: They analyse performance metrics and refine strategies, driving supply chain excellence.

g) Risk management and mitigation: 4PLs use their expertise to predict, address, and mitigate potential supply chain disruptions.

h) Single point of contact: Businesses can simplify communications, dealing with one entity for all Logistics concerns.

Distribution Logistics

Distribution Logistics is a balancing act of cost, efficiency, and customer satisfaction, pivotal in a product’s journey from manufacturer to market. Distribution Logistics focuses on efficiently delivering finished products to consumers, ensuring timely, accurate, and cost-effective reach.

a) Optimised transportation: Distribution Logistics selects the best transport modes, routes, and schedules for efficient delivery.

b) Warehousing strategies: Strategic storage solutions ensure products are readily available for dispatch as demand arises.

c) Inventory management: Balancing stock levels prevents overstocking or stockouts, ensuring consistent product availability.

d) Order processing: Efficient systems handle customer orders, ensuring accuracy and timely fulfilment.

e) Packaging considerations: Proper packaging preserves product quality and caters to branding and marketing needs.

f) Technology utilisation: Modern tools like tracking systems ensure transparency and real-time updates for customers.

g) Regulatory compliance: Adhering to regional and international transport regulations is crucial to avoid legal complications.

h) Returns and reverse Logistics: An integral part of ensuring that product returns are managed efficiently, reflecting positively on the brand.

Production Logistics

Production Logistics streamlines the in-house manufacturing process, focusing on providing an efficient flow of materials and finished goods.

Inventory optimisation: Efficient storage and timely retrieval of materials are vital for uninterrupted production.

Resource management: It's about the best use of human resources, machinery, and materials to achieve production targets.

Integrated production planning: Coordinating various stages of production ensures seamless operations and reduces bottlenecks.

Synchronised supply and demand: Balancing production with market demand minimises overproduction and stockpiling.

Quality assurance: Production Logistics also emphasises maintaining and enhancing product quality throughout the manufacturing process.

Safety protocols: Ensuring the safe handling, storage, and transportation of materials and products is paramount.

Feedback loops: Real-time monitoring and feedback mechanisms help adjust the production process quickly.

Green Logistics

Green Logistics offers sustainable and eco-friendly practices in the Logistics and supply chain sector, prioritising environmental responsibility.

Carbon footprint reduction: One primary objective is minimising greenhouse gas emissions from transportation and warehousing activities.

Alternative fuels: Adopting biofuels, electric vehicles, and other eco-friendly transportation methods reduce environmental harm.

Optimised route planning: Efficient route mapping decreases fuel consumption and, consequently, emissions.

Waste reduction: Green Logistics emphasises reducing, reusing, and recycling to minimise wastage and promote a circular economy.

Training and awareness: Continual training ensures employees are aligned with green objectives and can contribute effectively.

Conclusion

Each country, with its unique customs procedures, tariffs, and regulations, requires Different Types of Logistics expertise to ensure smooth transportation. Modern solutions integrate IoT, AI, and other technologies to streamline processes, predict demands, and provide real-time tracking. Customers today expect faster, traceable, and often free deliveries. Meeting these expectations necessitates Logistics that are agile and customer centric.

Optimise your supply chain journey with our Supply Chain Management Training today!

Frequently Asked Questions

Upcoming Business Skills Resources Batches & Dates

Date

Logistics Management Training

Logistics Management Training

Fri 17th Jan 2025

Fri 21st Mar 2025

Fri 16th May 2025

Fri 18th Jul 2025

Fri 19th Sep 2025

Fri 21st Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please