We may not have the course you’re looking for. If you enquire or give us a call on 01344 203999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Manual Handling is a fundamental aspect of various industries, involving the lifting, moving, and carrying of objects by hand or bodily force. While it may seem simple, improper handling can lead to injuries, both acute and chronic. Employers and employees alike have a crucial role in ensuring safe handling practices. Read this blog to learn about the Manual Handling Responsibilities of employers and employees and gain valuable insights to preventing workplace injuries.

Table of Contents

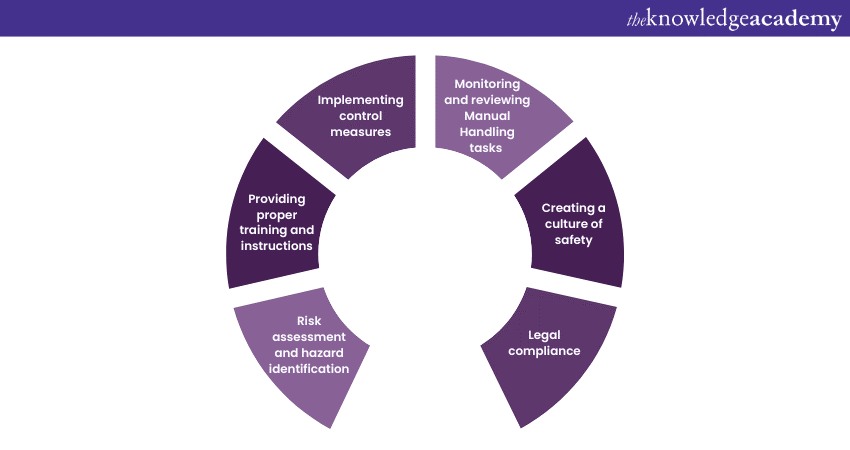

1) Employer’s Manual Handling Responsibilities

a) Risk assessment and hazard identification

b) Providing proper training and instructions

c) Implementing control measures

d) Monitoring and reviewing Manual Handling tasks

e) Creating a culture of safety

f) Legal compliance

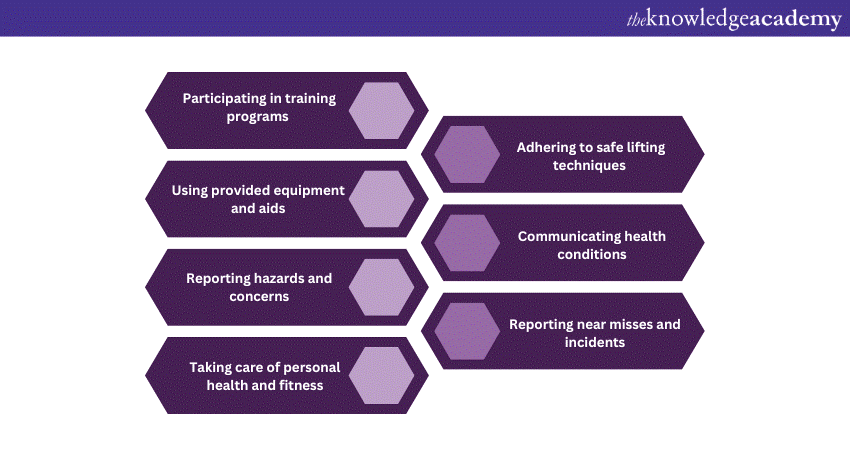

2) Employee’s Manual Handling Responsibilities

a) Participating in training programs

b) Using provided equipment and aids

c) Reporting hazards and concerns

d) Taking care of personal health and fitness

e) Adhering to safe lifting techniques

f) Communicating health conditions

g) Reporting near misses and incidents

3) Conclusion

Employer’s Manual Handling Responsibilities

Employers play a pivotal role in creating a safe and healthy work environment for their employees. Recognising the potential risks associated with Manual Handling tasks, they are obligated to take specific measures to ensure the well-being of their workforce. Here's an in-depth look at the responsibilities that employers need to fulfil:

Risk assessment and hazard identification

Before any Manual Handling tasks are undertaken, it is the duty of the employer to conduct a thorough Manual Handling Risk Assessment. This involves identifying potential hazards and evaluating the associated risks. By understanding the specific challenges of each task, employers can develop targeted strategies to mitigate risks. Risk assessment is an ongoing process that must be revisited whenever there are changes in the workplace, tasks, or equipment.

For example, a retail store that receives frequent shipments of merchandise. The store manager, as part of their employer responsibilities, conducts a risk assessment to identify potential Manual Handling Hazard. They recognise that lifting and moving heavy boxes during restocking activities can pose risks to employees.

Learn more about Health & Safety in the Workplace today!

Providing proper training and instructions

Employers are responsible for ensuring that their employees receive adequate training and instruction on safe Manual Handling Techniques. This training should encompass the principles of ergonomic lifting, correct posture, and the proper use of equipment and aids. Clear and comprehensible instructions should be given to employees, enabling them to perform their tasks safely and effectively.

For example, the store manager arranges a training session for all employees involved in restocking tasks. During this session, employees are taught proper lifting techniques, the importance of maintaining good posture, and how to recognise their limits when handling heavy items. Clear instructions are given on how to use available equipment, such as trolleys or dollies, to minimise the strain on their bodies.

Implementing control measures

To reduce the risks associated with Manual Handling, employers must implement control measures. This can involve engineering controls, such as providing mechanical aids and ergonomic equipment, as well as administrative controls, like altering work schedules to minimise strenuous tasks. The aim is to lessen the physical demands on employees and create an environment that promotes safe practices.

For instance, to reduce the risk of injuries, the store manager invests in wheeled trolleys and stackable crates to assist with the movement of merchandise. This equipment enables employees to transport items more easily, minimising the need for manual lifting.

Monitoring and reviewing Manual Handling tasks

Constant vigilance is necessary to maintain a safe working environment. Employers should regularly monitor and review Manual Handling tasks to ensure that safe practices are being followed. This might involve observing employees during their tasks, analysing incident reports, and seeking feedback from workers. The insights gained from these observations can help identify areas for improvement and drive continuous enhancement of safety measures.

For example, the store manager observes employees while they engage in restocking activities. This monitoring helps identify any deviations from proper lifting techniques and provides an opportunity for immediate correction. The manager also encourages employees to provide feedback and share their experiences, which contributes to ongoing improvement.

Creating a culture of safety

Fostering a culture of safety is paramount to the success of any workplace. Employers need to lead by example and promote a mindset where safety is prioritised above all else. Open communication channels should be established, encouraging employees to voice their concerns and suggestions without fear of repercussions. Regular safety meetings and discussions can help maintain awareness and keep safety at the forefront of everyone's minds.

Legal compliance

Employers must be aware of and adhere to relevant health and safety regulations. These regulations are in place to protect the well-being of employees and ensure a safe working environment. By complying with these regulations, employers not only prevent potential legal repercussions but also demonstrate their commitment to the safety and welfare of their workforce.

Employee’s Manual Handling Responsibilities

While employers bear the primary responsibility for creating a safe Manual Handling environment, employees also play a vital role in ensuring their own well-being and that of their colleagues. By actively participating in training programs, adhering to safe practices, and communicating effectively, employees contribute significantly to maintaining a hazard-free workplace. Let's get into the responsibilities that employees should uphold:

Participating in training programs

Employees must actively engage in the training and education programs provided by their employers. These programs are designed to equip them with the knowledge and skills needed to perform Manual Handling tasks safely. By attending these sessions, employees gain insights into ergonomic techniques, proper lifting postures, and the correct use of equipment and aids.

Example, employees eagerly participate in the training sessions arranged by the store manager. They actively listen and practice the techniques demonstrated to them, such as bending their knees and using their leg muscles to lift.

Using provided equipment and aids

Utilising the equipment and aids provided by the employer is crucial to safe Manual Handling. Employees should make full use of mechanical tools, lifting devices, and ergonomic furniture to reduce the physical strain associated with manual tasks. Failing to use these resources can increase the risk of injury, not only to oneself but also to colleagues who may need to assist or work alongside.

For example, during restocking, employees use the trolleys and crates provided by the employer to move heavy merchandise. They recognise the importance of utilising these aids to minimise the physical strain on their bodies. This proactive approach demonstrates their commitment to safe Manual Handling practices.

Reporting hazards and concerns

Employees are the frontline observers of potential hazards and Manual Handling risks. It is their responsibility to promptly report any hazards or concerns related to Manual Handling tasks. This includes identifying unsafe work conditions, faulty equipment, or practices that deviate from established safety protocols. By reporting such issues, employees contribute to the overall improvement of workplace safety.

For instance, if an employee notices that a trolley's wheels are faulty or a pathway is obstructed, they promptly report these hazards to their supervisor. By communicating such concerns, they actively contribute to the maintenance of a hazard-free work environment for themselves and their colleagues.

Taking care of personal health and fitness

Maintaining good personal health and physical fitness is vital for safe Manual Handling. Employees should strive to stay in good physical condition, as this enhances their ability to carry out tasks safely and with reduced risk of injury. Engaging in regular exercise, maintaining a balanced diet, and seeking medical advice for pre-existing health conditions can all contribute to individual well-being.

Adhering to safe lifting techniques

Employees should always employ proper lifting techniques when handling objects manually. This involves bending the knees, keeping the back straight, and using the leg muscles to lift rather than the back. Avoiding sudden jerky movements and lifting within one's capacity can significantly decrease the risk of strains and injuries.

For example, Employees consistently apply the lifting techniques taught during the training sessions. They avoid bending from the waist, opting instead to bend their knees and keep their backs straight while lifting. By practising these techniques, they significantly reduce the risk of straining their muscles or injuring their backs.

Communicating health conditions

Employees should communicate any pre-existing health conditions that might affect their ability to engage in Manual Handling tasks safely. These conditions could include back problems, heart conditions, or pregnancy. By informing their supervisors about these concerns, employees allow for appropriate adjustments to be made to their tasks or work environment to ensure their well-being.

For example, an employee who has recently recovered from a back injury informs their supervisor about their health condition before participating in Manual Handling tasks. This communication allows the supervisor to assign tasks that are within the employee's capabilities and make any necessary accommodations.

Reporting near misses and incidents

Near misses and incidents provide valuable opportunities for learning and improvement. Employees should report any near misses (situations where an accident almost occurred) or actual incidents related to Manual Handling tasks. These reports help identify trends, root causes, and areas that require additional attention, ultimately contributing to a safer workplace.

For example, during a restocking session, an employee experiences a near miss where a heavy box almost slips from their grip. They immediately report this incident to their supervisor. This report helps the management identify potential areas for improvement in the handling of merchandise.

Conclusion

We hope you enjoyed reading this blog on Manual Handling Responsibilities. It is an essential aspect of various industries, but it comes with inherent risks. Employers and employees must collaborate to ensure safe practices are followed to prevent injuries and create a productive work environment. Understanding the responsibilities on both sides, implementing proper training, utilising equipment, and adhering to ergonomic principles, we can significantly reduce the risk of injuries. Remember, safety is a collective effort that requires continuous communication, education, and commitment.

Try out our Manual Handling At Work Course today!

Frequently Asked Questions

Upcoming Health & Safety Resources Batches & Dates

Date

Manual Handling at Work

Manual Handling at Work

Fri 17th Jan 2025

Fri 7th Mar 2025

Fri 23rd May 2025

Fri 18th Jul 2025

Fri 12th Sep 2025

Fri 14th Nov 2025

Fri 12th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please