We may not have the course you’re looking for. If you enquire or give us a call on +44 1344 203 999 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Are you interested in simplifying your business procedures and enhancing productivity? Then, PDCA Cycle can help you. But What is PDCA? The PDCA Cycle, consisting of Plan, Do, Check, Act, provides a successful approach for ongoing enhancement in different sectors. It is a flexible instrument utilised in quality management and business strategies to promote innovation and expansion.

This blog will help you understand What is PDCA and how it assists in pinpointing improvement areas, making and applying changes. Learn how this continuous improvement methodology helps optimise processes, enhance efficiency, and drive quality in your organisation.

Table of Contents

1) Understanding PDCA

2) The Four Phases of the PDCA Cycle

3) When to Implement the PDCA Cycle?

4) An Example of the PDCA Cycle

5) Conclusion

Understanding PDCA

Plan-Do-Check-Act (PDCA) is a continuous improvement cycle for people, products, services, and business processes. The concept was initially developed by Walter Shewhart.

He is an American statistician and physicist, who highlighted using statistical analysis for quality improvement. William Deming later expanded on Shewhart's ideas and turned them into a learning and improvement cycle.

The Four Phases of the PDCA Cycle

The PDCA Cycle is an iterative process aimed at continuously improving products, people, and services. It has become a key component of Lean management. The Plan-Do-Check-Act model involves testing solutions, analysing results, and enhancing processes.

For instance, if you receive numerous complaints about your support team's slow response rate, you'll need to improve their performance to keep customers happy. This is where PDCA comes into play.

Now, let's explore the four stages of the PDCA process in detail.

1) Plan

Begin by recognising and comprehending the issue or improvement opportunity in front of you. The finished product may lack quality, or a specific area of your marketing strategy needs enhancing. Carefully investigate all accessible data, generate ideas through brainstorming, and create a detailed plan for execution. Clearly articulate your success indicators and verify they are quantifiable, as they will be reviewed during the Check phase.

2) Do

Have a potential solution ready and carry out a small pilot project to evaluate its efficiency. This trial aims to see if the suggested alterations lead to the expected outcomes, reducing possible disruptions to the overall function in case of failure.

For example, you could conduct the test in a particular department, in a small geographical location, or focus on a specific group of people. Gather information during the pilot phase to assess the effectiveness of the modifications.

3) Check

Evaluate the outcomes of your pilot initiative based on the standards set in the planning stage to ascertain the effectiveness of the modifications. If the results fall short of expectations, return to the Planning stage.

If this is accomplished, proceed to the next stage. You can make extra modifications and iterate through the Do and Check steps to enhance your method even more.

4) Act

Execute the effective resolution on a grander level. Remember that the PDCA Cycle is an ongoing loop, not a single instance. Your upgraded process or product will set a new benchmark, prompting you to pursue more improvements to sustain a continuous enhancement culture consistently.

This cyclic method guarantees that your company always grows and adjusts, promoting a culture of ongoing enhancement and creativity.

Become a certified Lead Auditor with ISO 9001 Lead Auditor Course- Sign up now!

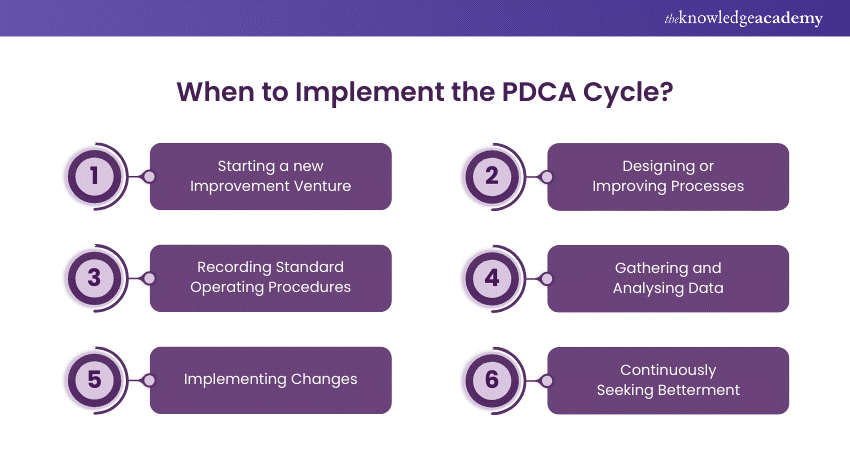

When to Implement the PDCA Cycle?

The PDCA Cycle addresses and solves Project Management and process improvement issues. It can be applied to various projects. Teams that use the PDCA Cycle effectively focus on continuous improvement.

Instead of using it as a one-time process, the PDCA Cycle ensures ongoing improvement through iteration. The PDCA Cycle is especially effective when you aim to:

1) Starting a new Improvement Venture: Employ PDCA to decrease defects, improve cycle times, or maximise resource usage.

2) Designing or Improving Processes: PDCA assists in guaranteeing quality and efficiency, whether it involves creating something innovative or improving existing offerings.

3) Recording Standard Operating Procedures: Great for establishing consistency and quality by standardising routine tasks.

4) Gathering and Analysing Data: Collecting and analysing data systematically with the help of PDCA helps identify problems or root causes.

5) Implementing Changes: Whether it's process, organisational, or technological changes, the PDCA Cycle aids in effectively planning and implementing changes.

6) Continuously Seeking Betterment: PDCA promotes a mindset of constant improvement, urging teams to adjust and enhance their efforts consistently.

Enhance your Auditing skills with ISO 9001 Internal Auditor Training- Register now!

An Example of the PDCA Cycle

Let’s take the example of Regional Blue Hospitals to see how the PDCA Cycle is implemented. Firstly, the hospital forms a team to identify the high frequency of healthcare-related infections (HAIs). In this case, the patients get secondary infections in the hospital. Now, the PDCA team follows this cycle:

a) Plan: The team sets its goals beforehand, such as reducing HAIs by 25%. It also investigates possible causes of the issue, such as a poor air filtration system.

b) Do: The team brief that poor employee training contributes to HAI issues. They plan to apply a complete training program for employees to protect against secondary infections.

c) Check: After a few months, the team creates new training protocols and rules to monitor whether the nurses adhere to them.

d) Act: This cycle will be considered adequate if the training serves perfectly and the PDCA team is satisfied with the outcomes. In contrast, if the training fails to reduce HAIs, the team will revisit and make proper adjustments in strategies.

Enhance operational efficiency across your organisation with our ISO 9001 Certification – Register now!

Conclusion

We trust that this blog has helped you grasp the idea of ‘What is PDCA’ for ongoing improvement. Through strategic and organised methods of preparing, executing, monitoring, and responding to adjustments, businesses can efficiently tackle problems. Additionally, understanding frameworks like OODA vs PDCA can offer deeper insights into decision-making and improvement processes. Also, they can improve operations and promote creativity. The PDCA Cycle facilitates continuous improvement and adaptability in quality management, project development, and daily operations.

Kickstart your journey to ISO 9001 with our ISO 9001 Lead Implementer Certification today!

Frequently Asked Questions

What is the Difference Between PDSA and PDCA?

Plan-Do-Study-Act (PDSA) focuses on testing and learning from changes, emphasising iterative improvement. Plan-Do-Check-Act (PDCA) is broader, targeting process control and consistency. PDSA is ideal for innovation, while PDCA suits routine operations and maintaining quality standards.

What are the Best Practices When Implementing a PDCA Cycle?

Define clear goals, involve stakeholders, and use data to guide decisions. Ensure thorough planning, document each phase, and focus on root cause analysis. Continuously monitor progress and adjust actions as needed to maintain alignment with objectives. Regularly review and refine the cycle for sustained improvements.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 3,000 online courses across 490+ locations in 190+ countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are the Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various ISO 9001 Certification, including ISO 9001 Foundation Course, ISO 9001 Lead Auditor Course and ISO 9001 Lead Implementer Certification. These courses cater to different skill levels, providing comprehensive insights into ISO 9001.

Our Health & Safety Blogs cover a range of topics offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Business Analysis skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

ISO 17020 Foundation Training

ISO 17020 Foundation Training

Mon 7th Jul 2025

Mon 8th Sep 2025

Mon 3rd Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please