We may not have the course you’re looking for. If you enquire or give us a call on +352 8002-6867 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

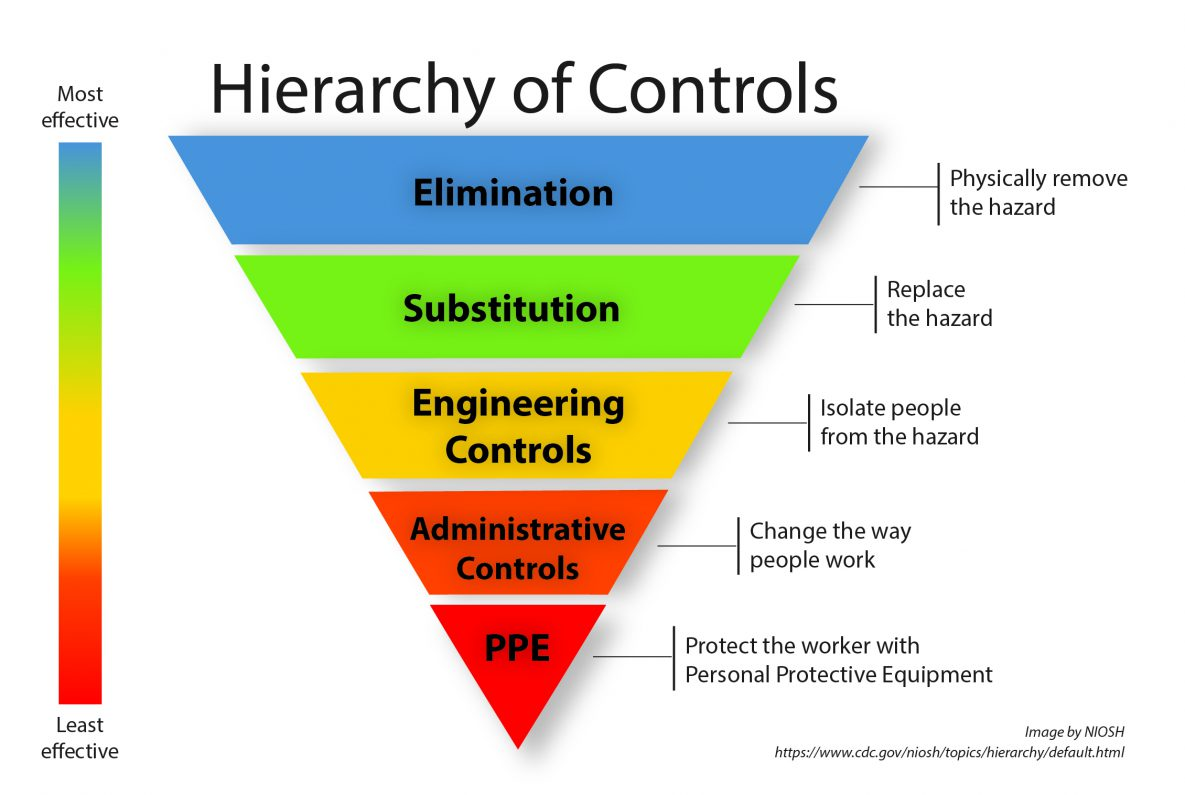

To create a safe working environment, the Hierarchy of Control plays a crucial role in health and safety management. As part of the NEBOSH (National Examination Board in Occupational Safety and Health) syllabus, the Hierarchy of Control provides a structured approach to identify and implement effective measures to eliminate or reduce workplace hazards.

According to a report by HSE, in the year 2021/22, 123 workers were killed in work-related accidents in the UK alone, and 565,000 workers sustained a non-fatal injury. Many organisations fail to implement a robust safety system in their workplace, and many workplaces need the technical know-how of work safety. This blog will explore the importance of the Hierarchy of Control, examine its five levels, and discuss how to implement these controls effectively.

Table of Contents

1) What is Hierarchy of Control in NEBOSH?

2) The levels in Hierarchy of Control

a) Elimination

b) Substitution

c) Engineering controls

d) Administrative controls

e) PPE

3) Conclusion

What is Hierarchy of Control in NEBOSH?

The Hierarchy of Control is a fundamental concept in occupational health and safety that focuses on eliminating or minimising workplace hazards. It provides a systematic framework that guides organisations in selecting the most effective control measures to ensure a safe and healthy work environment. NEBOSH, an internationally recognised organisation, incorporates the Hierarchy of Control as a cornerstone of its health and safety courses.

The primary objective of the Hierarchy of Control is to prevent incidents, injuries, and illnesses by addressing hazards at their source. It emphasises the importance of taking proactive measures to eliminate hazards rather than relying solely on personal protective equipment (PPE) or reactive solutions. By following this approach, organisations can create a safer workplace and promote a culture of prevention.

Gain the necessary skills to manage safety and health in an environment or workplace and get certified with our NEBOSH National General Certificate In Occupational Health And Safety Training course.

The levels in Hierarchy of Control

The Hierarchy of Control consists of five levels, each representing a different approach to risk control. These levels are presented in descending order of effectiveness, with the most effective measures at the top.

Elimination

At the top level is the elimination control, which involves completely removing the hazard from the workplace. This is the most effective control measure since it eradicates the risk entirely. Elimination can be achieved through various means, such as.

1) Redesigning processes by modifying workflows or procedures to eliminate the need for hazardous tasks or materials. For example, replacing the manual lifting process with a mechanised system.

2) Substituting hazardous materials with less dangerous alternatives. For instance, using non-toxic cleaning agents instead of chemical-based cleaners.

3) Identifying alternative methods or technologies so that the need for carrying out the hazardous task is eliminated. For instance, using remote-controlled machinery for tasks in hazardous environments.

Interested to know the validityof your nebosh certification refer to our blog on "Nebosh Certificate validity"

Implementing elimination control measures requires a systematic approach. Employers should conduct thorough Nebosh risk assessments, identify hazardous activities or substances, and explore viable alternatives. Collaboration with employees, experts, and relevant stakeholders is crucial to identify and implement effective elimination strategies.

Understand the fundamentals of safety at work and reasons for practising good standards of safety with our NEBOSH Award In Health And Safety At Work training and qualification.

Substitution

If elimination is not feasible, substitution is the next level in the Hierarchy of Control in NEBOSH. Substitution involves replacing hazardous substances, equipment, or processes with less hazardous alternatives, and this level minimises the risk by introducing safer elements into the workplace. Some examples of substitution include:

1) Using non-toxic or less toxic substances by replacing harmful chemicals with safer alternatives that serve the same purpose.

2) Employing safer equipment or machinery and replacing outdated or malfunctioning equipment with newer models that incorporate advanced safety features.

3) Adopting alternative processes and implementing methods that reduce exposure to hazards. For instance, using mechanical methods instead of manual cutting or grinding.

Organisations must conduct thorough research to implement substitution effectively to identify suitable alternatives. They should assess the performance, availability, and compatibility of the alternatives and ensure proper training and education on their use. Regular maintenance, inspection, and testing are essential to ensure the ongoing effectiveness of these controls.

Learn more and crack your NEBOSH interview with our blog on Nebosh question paper.

Engineering Controls

The third level in the Hierarchy of Control in NEBOSH is engineering controls, which focuses on isolating workers from hazards through engineering solutions. This level emphasises the physical modification of the workplace or processes to minimise exposure to risks. Engineering controls include:

1) Installing physical barriers like guards or barriers to separate workers from machinery or hazardous areas.

2) Improving airflow and ventilation to reduce exposure to airborne contaminants.

3) Introducing automated machinery or robotics to replace hazardous manual tasks.

Implementing engineering controls requires carefully assessing the workplace and the hazards involved. Engineering control is not about eliminating the root cause of a hazard. Instead, it works to limit the exposure to the hazard. Therefore, these controls may not be as effective. Although, they serve well as an immediate solution that reduces the risk of getting in contact with the hazard. Employers should consult engineers and safety professionals to identify appropriate engineering control measures.

Administration

When engineering controls are not sufficient or feasible, administrative controls are implemented. This level involves changing work practices, procedures, or policies to reduce the risk. Administrative controls focus on modifying human behaviour and work conditions. Examples of administrative controls include:

1) Providing comprehensive training to employees on hazard awareness, safe work practices, and emergency procedures.

2) Rotating employees through different tasks or providing regular breaks to minimise exposure to hazards.

3) Limiting access to hazardous areas or establishing designated safety zones.

Keen on starting a career in Nebosh, refer to our blog on "Nebosh National Diploma vs International Diploma"

When engineering controls are used with administrative controls, it can effectively reduce the risks or chances of mishaps in the workplace. Administrative controls require effective communication, clear policies, and robust training programs. Employers should ensure that employees receive appropriate training and supervision to adhere to the established procedures.

Interested in clearing and knowing the exam pattern, refer to our blog on "Nebosh Open Book Examination"

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is the last line of defence in the Hierarchy of Control. It includes equipment such as helmets, gloves, goggles, masks, and safety shoes. While PPE protects workers from hazards, it should only be used when other control measures cannot adequately mitigate the risks. PPE should be selected, provided, and used correctly. Employers must:

1) Conduct assessments to determine the specific PPE required for each task and hazard.

2) Provide appropriate training on PPE use, maintenance, and limitations.

3) Regularly inspect and replace worn-out or damaged PPE.

4) Encourage compliance and enforce the use of PPE through policies and procedures.

5) PPE should always be considered a temporary measure while efforts are made to implement higher levels of control.

Strengthen your understanding on nebosh, refer our blog on "Difference between IOSH, Nebosh and Osha"

Conclusion

Implementing the NEBOSH Hierarchy of Control requires a systematic approach, starting with identifying hazards, evaluating risks, and selecting the most effective control measures at each level. It is crucial to remember that control measures may need to be combined and implemented in conjunction with each other to provide effective risk management. By applying the hierarchy of Control, organisations can significantly enhance workplace safety and protect the health and well-being of their employees.

Become a leader and acquire the skills to lead your workplace in occupational health and safety with our NEBOSH HSE Certificate In Health And Safety Leadership Excellence Training.

Frequently Asked Questions

The Hierarchy of Control provides a systematic approach to managing workplace hazards by prioritising the most effective control measures, from elimination to personal protective equipment (PPE), ensuring a safer work environment.

The Hierarchy of Control is a system for managing risks by prioritising actions like elimination and substitution, while Principles of Prevention focus on avoiding risks and promoting a safety culture.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various NEBOSH Courses, including the NEBOSH Award In Health and Safety at Work Course, NEBOSH Working with Wellbeing Training and NEBOSH HSE Award in Managing Risks and Risk Assessment at Work Training. These courses cater to different skill levels, providing comprehensive insights into Importance of Safety at Workplace.

Our Health & Safety Blogs cover a range of topics related to health and safety, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your mitigate risk skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Health & Safety Resources Batches & Dates

Date

NEBOSH Award in Health and Safety at Work

NEBOSH Award in Health and Safety at Work

Mon 3rd Feb 2025

Mon 7th Apr 2025

Tue 27th May 2025

Mon 21st Jul 2025

Mon 15th Sep 2025

Mon 10th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please