We may not have the course you’re looking for. If you enquire or give us a call on +352 8002-6867 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Are you looking for ways to make your business more efficient and productive? Lean methodology might be just what you need! By focusing on reducing waste and optimising processes, Lean can transform how your organisation operates. This blog covers essential Lean Tools like 5S, Kaizen, and Value Stream Mapping, offering practical strategies to streamline your operations and enhance performance.

Whether you're new to Lean or eager to expand your knowledge, these tools provide the keys to continuous improvement. Ready to take your business to the next level? Let’s explore these Lean Tools together!

Table of Contents

1) What is Lean?

2) Lean Tools and Techniques for Process Improvement

a) 5S

b) Kaizen

c) Standardised Work

d) Just-in-Time (JIT)

e) Bottleneck Analysis

f) Six Sigma

j) Single-Minute Exchange or Die (SMED)

k) Root Cause Analysis

l) Plan-Do-Check-Act (PDCA)

m) Error Proofing

3) Conclusion

What is Lean?

Lean is a methodology focused on creating more value for customers by optimising processes, eliminating waste, and improving overall efficiency. Originating from the Toyota Production System, Lean emphasises continuous improvement and respect for people, helping organisations deliver better products or services.

Lean aims to do more with less by identifying activities that do not add value. This saves cost, improves quality and engages the workforce. By focusing on what truly matters, businesses can create a culture of continuous improvement.

Lean Tools and Techniques for Process Improvement

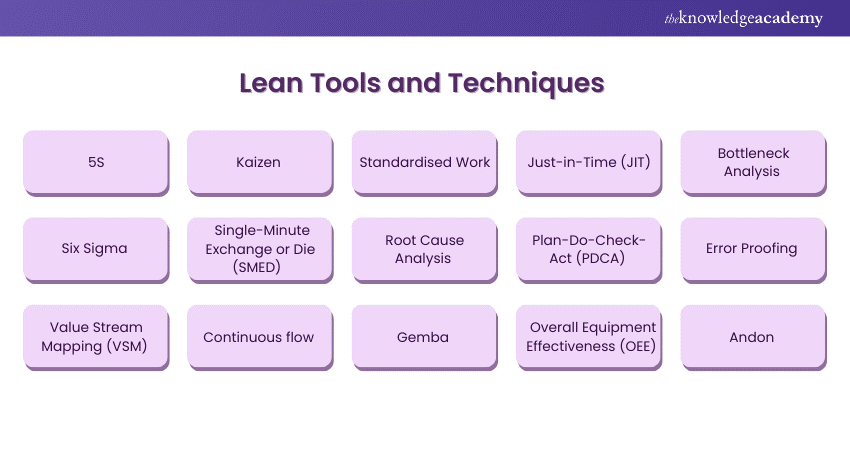

Lean Tools are specific techniques and strategies that help implement Lean principles in an organisation. These tools provide practical ways to identify inefficiencies, solve problems, and drive continuous improvement. Here are the top 15 Lean Tools that can significantly enhance business efficiency:

1) 5S

5S is a workplace organisation method that stands for Sort, Set in Order, Shine, Standardise, and Sustain. This tool helps create a clean and organised work environment by removing clutter, arranging items logically, maintaining cleanliness and standardising procedures.

a) Sort: Remove unnecessary items from the workspace

b) Set in Order: Organise tools and materials for easy access

c) Shine: Clean the workspace regularly to maintain tidiness

d) Standardise: Establish standards for organising and cleaning

e) Sustain: Maintain the improvements through regular audits

2) Kaizen

It is a Japanese term meaning "continuous improvement." It encourages employees at all levels to implement small, incremental changes that can lead to improvements over time. Kaizen fosters a culture of collaboration and innovation, empowering employees to take ownership of their work.

The Kaizen process typically involves identifying a problem, analysing it, brainstorming solutions, implementing changes, and reviewing the results. By continually seeking ways to improve, businesses can enhance efficiency, quality, and employee satisfaction.

3) Standardised Work

Standardised Work involves documenting the best practices for performing a task or process. By establishing a consistent way of doing things, organisations can ensure that work is done efficiently and effectively, reducing variations and errors.

Standardised Work includes detailed instructions, time requirements, and quality standards. It acts as a baseline for continuous improvement, allowing employees to identify areas for enhancement and share best practices across the organisation.

4) Just-in-Time (JIT)

It is a production strategy that aims to produce and deliver products precisely when they are needed, reducing inventory and minimising waste. JIT focuses on having the right amount of materials at the right time, eliminating excess stock and reducing carrying costs.

Implementing JIT requires close collaboration with suppliers, efficient production scheduling, and a responsive supply chain. By aligning production with customer demand, businesses can reduce waste and improve customer satisfaction.

5) Bottleneck Analysis

Bottleneck Analysis identifies constraints or bottlenecks in a process that limits its overall efficiency. By pinpointing these bottlenecks, organisations can take corrective actions to improve the flow of work and increase productivity.

The analysis involves mapping out the process, identifying the slowest or most congested points, and implementing changes to alleviate the bottleneck. By addressing these constraints, businesses can achieve smoother operations and better utilise resources.

Build a strong foundation in Lean Principles with our Certified Lean Foundation Course- Join today!

6) Six Sigma

Six Sigma is a data-driven methodology aimed at reducing defects and improving quality by identifying and eliminating variations in processes. It uses statistical tools and techniques to analyse and improve processes, ensuring that products or services meet customer expectations.

Six Sigma follows a structured approach known as DMAIC (Define, Measure, Analyse, Improve, Control) to drive improvements. By focusing on quality, businesses can reduce errors and enhance customer satisfaction.

7) Single-Minute Exchange or Die (SMED)

SMED is a Lean Tool that focuses on reducing setup times in manufacturing processes. By minimising the time required to change equipment or production lines, businesses can increase flexibility and responsiveness to customer demands.

SMED involves separating internal and external setup activities, streamlining procedures, and implementing quick-change techniques. By reducing setup times, organisations can achieve shorter lead times, lower costs, and higher productivity.

8) Root Cause Analysis

Root Cause Analysis (RCA) is a problem-solving method used to find the underlying cause of an issue. Rather than addressing symptoms, RCA seeks to uncover the root cause to prevent recurrence and achieve lasting solutions.

RCA typically involves tools like the "5 Whys" and fishbone diagrams to explore cause-and-effect relationships. By understanding the true cause of a problem, businesses can implement effective corrective actions and improve overall performance.

9) Plan-Do-Check-Act (PDCA)

PDCA is a cyclical process used for continuous improvement and problem-solving. It involves four stages: Plan, Do, Check, and Act.

a) Plan: Identify a problem and develop a plan to address it

b) Do: Implement the plan on a small scale

c) Check: Evaluate the results and analyse the data

d) Act: Make necessary adjustments and implement improvements

PDCA encourages organisations to test and refine solutions, promoting a culture of learning and adaptation

Master Lean principles to optimize efficiency, reduce waste, and streamline your processes with our comprehensive Lean Training today!

10) Error Proofing

Error Proofing, also known as poka-yoke, is a technique that prevents mistakes by designing processes or products to eliminate errors. It involves implementing mechanisms that detect and correct mistakes before they lead to defects.

These techniques can include checklists, alarms, sensors, and other controls that ensure tasks are performed correctly. By preventing errors at the source, businesses can reduce defects and improve quality.

11) Value Stream Mapping (VSM)

VSM is a visual tool used to analyse and improve the flow of materials and information through a process. It provides a detailed view of the current state and helps identify areas for improvement.

VSM involves mapping out each step of a process, highlighting value-added and non-value-added activities. By visualising the entire process, organisations can identify inefficiencies, reduce waste, and create a more streamlined operation.

12) Continuous flow

Continuous Flow is a Lean concept that aims to move products or services through a process without interruptions or delays. It emphasises a smooth and efficient workflow, reducing waiting times and improving productivity.

Implementing continuous flow requires optimising workstations, reducing batch sizes, and minimising handoffs between processes. By achieving a continuous flow, businesses can reduce lead times, increase flexibility, and enhance customer satisfaction.

13) Gemba

It is a Japanese term meaning "the real place," referring to the actual location where work is done. In Lean, Gemba involves going to the source to observe and understand processes firsthand.

Gemba encourages leaders and managers to engage with employees, identify problems, and collaborate on solutions. By being present at the worksite, organisations can gain valuable insights, build trust, and drive continuous improvement.

14) Overall Equipment Effectiveness (OEE)

OEE is a metric used to measure the performance of equipment in a manufacturing process. It considers three factors: availability, performance, and quality.

a) Availability: Measures the equipment's uptime

b) Performance: Assesses how well the equipment is operating compared to its maximum capacity

c) Quality: Evaluates the quality of products produced

By monitoring OEE, businesses can identify areas for improvement, optimise equipment utilisation, and enhance productivity.

15) Andon

It is a visual management tool that alerts workers and supervisors to issues or abnormalities in a process. It typically involves lights or signals that indicate the status of a machine or production line.

Andon systems empower employees to stop the production process when problems arise, ensuring that issues are addressed promptly. By promoting transparency and accountability, Andon helps organisations maintain quality and efficiency.

Conclusion

Lean Tools offer practical strategies for improving business efficiency, reducing waste, and enhancing productivity. By implementing Lean principles and utilising these tools, organisations can deliver greater value to their customers. Embrace Lean and experience the benefits of streamlined operations, improved quality, and engaged employees. With continuous improvement as a core focus, Lean empowers businesses to succeed in a constantly changing market.

Embark on a Lean transformation with our Introduction To Lean Course –Register now!

Frequently Asked Questions

The 7 Lean principles are value, value stream, flow, pull, perfection, respect for people, and continuous improvement. These principles guide businesses in creating efficient processes by focusing on delivering value to customers while minimising waste.

7S is an extension of the 5S methodology and includes Sort, Set in Order, Shine, Standardise, Sustain, Safety, and Spirit. It focuses on organising the workplace, improving safety, and fostering a work culture to enhance productivity and efficiency.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Lean Training, including Introduction to Lean, Certified Lean Foundation & Practitioner, 5S Training and Advanced Lean Techniques and Understanding Customers Training. These courses cater to different skill levels, providing comprehensive insights into Lean Six Sigma Green Belt Principles.

Our Business Improvement Blogs cover a range of topics related to Lean Principles, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Business skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Introduction to Lean

Introduction to Lean

Wed 11th Dec 2024

Fri 7th Feb 2025

Fri 16th May 2025

Fri 5th Sep 2025

Fri 5th Dec 2025

Halloween sale! Upto 40% off - Grab now

Halloween sale! Upto 40% off - Grab now

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please