We may not have the course you’re looking for. If you enquire or give us a call on +91-181-5047001 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

In an era where efficiency and innovation dictate success, Lean Methodology emerges as a game-changing approach for businesses striving to optimise their processes and eliminate waste. But What is Lean Methodology? In this complete guide, we will analyse the meaning and concepts of Lean Methodology and how to implement its strategies effectively.

Whether you're a seasoned professional or an inquisitive learner, this blog will provide you with the insights needed to harness the full potential of Lean Methodology. Get ready to take your operations to a higher level of success.

Table of Contents

1) What is Lean Methodology?

2) Core Principles of Lean Methodology

3) Advantages of Lean Methodology

4) Challenges of Lean Methodology

5) Conclusion

What is Lean Methodology?

Lean Methodology is a systematic approach to improving efficiency. It aims to eliminate waste in processes. Waste refers to any activity that doesn't contribute value to the final product. Lean focuses on maximising customer value while minimising resources.

By cutting waste, Lean Methodology enhances processes, enabling teams to deliver greater value to customers. Embracing Lean can significantly transform an organisation’s efficiency.

History of Lean Methodology

The roots of Lean Methodology trace back to Toyota in the 1940s. The company aimed to innovate production processes. This focus led to the Toyota Production System (TPS), which emphasised efficiency. Over time, these principles formed the foundation of Lean Methodology.

In the 1980s, lean concepts gained popularity outside Japan. Businesses worldwide recognised its power in enhancing productivity. Today, Lean Methodology is integral to manufacturing, healthcare, and service industries.

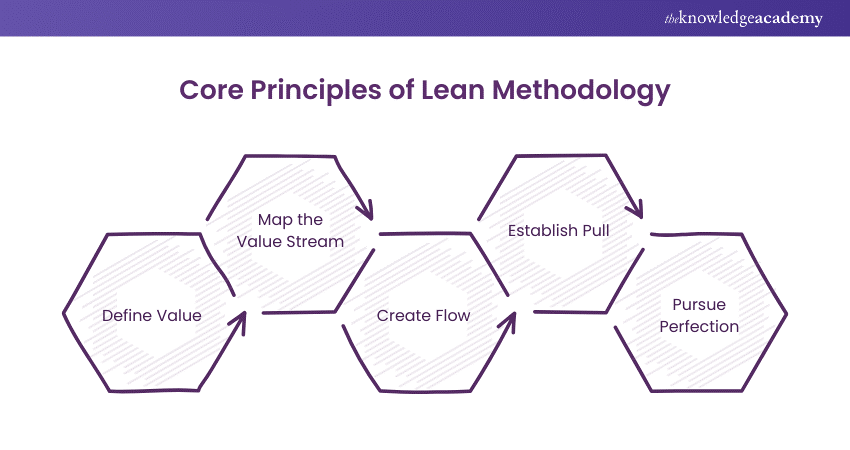

Core Principles of Lean Methodology

Lean Methodology focuses on maximising value while minimising waste. Let’s explore its core principles.

1) Define Value

The first step in Lean Methodology is to clearly define value. Value is what the customer perceives as beneficial. It is critical to understand what customers truly want. This understanding helps in identifying valuable features or services.

Focusing on customer value guides the entire process design. All efforts should align with enhancing this value.

2) Map the Value Stream

Once value is defined, the next step is mapping the value stream. A value stream encompasses all the actions needed to deliver a product or service. This includes both value-adding and non-value-adding activities.

By visualising the entire process, you can identify inefficiencies. Mapping helps to highlight where waste occurs. The goal is to streamline these processes for better efficiency.

3) Create Flow

Creating flow is about ensuring that the value-adding steps operate smoothly. In a lean context, flow means that products or services move efficiently through the process. This can be achieved by reducing delays and eliminating bottlenecks.

A smooth flow leads to quicker service delivery. It improves productivity and customer satisfaction significantly. Maintaining flow requires continuous monitoring and adjustments.

4) Establish Pull

The principle of establishing pull means producing only what is needed. Instead of pushing products into the market, organisations should respond to customer demand. This reduces excess inventory and waste.

Pull systems prioritise efficiency and ensure resources are used effectively. By aligning production with actual demand, companies can maximise their resources. It creates a more responsive and adaptable environment.

5) Pursue Perfection

The final principle of Lean Methodology is the pursuit of perfection. Lean is an ongoing journey, not a one-time event. Continuous improvement, or "Kaizen", is essential. Organisations must consistently evaluate and refine their processes.

This means encouraging feedback and fostering a culture of innovation. Striving for perfection leads to higher quality and enhanced customer satisfaction. The objective is to eliminate waste and improve every aspect of the business continually.

Enhance your team's efficiency and reduce waste with our Lean Courses. Start transforming your processes today!

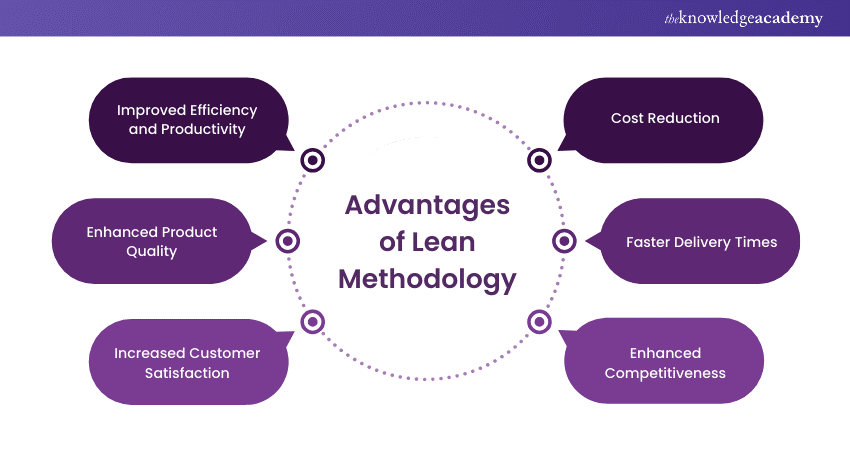

Advantages of Lean Methodology

Lean Methodology provides a framework for organisations to enhance their processes continually. Below, we delve into the numerous advantages of implementing Lean Methodology.

1) Improved Efficiency and Productivity

Lean Methodology focuses on streamlining processes. It helps organisations identify non-value-added activities. By minimising these activities, teams can concentrate on essential tasks.

This results in improved workflow and higher productivity levels. Increased efficiency also translates to quicker project completion. Ultimately, this boosts overall operational performance.

2) Enhanced Product Quality

Quality is a fundamental aspect of Lean Methodology. Lean encourages continuous improvement through regular feedback. This iterative approach helps identify quality issues early.

Teams can then address these concerns promptly. As a result, product defects decrease significantly. Customers receive higher-quality products that meet their expectations consistently.

3) Increased Customer Satisfaction

Customer satisfaction is central to Lean principles. When companies focus on value, they meet customer needs more effectively. This leads to a better overall customer experience.

By continuously improving processes, organisations can respond to customer feedback efficiently. Happier customers are likely to become loyal repeat buyers. Therefore, investing in Lean practices can significantly enhance customer loyalty.

4) Cost Reduction

Lean Methodology helps identify wasteful spending in processes. By eliminating inefficiencies, organisations can reduce operational costs. This includes minimising excess inventory, overproduction, and rework.

Money saved can be redirected into other important parts of the company. Those savings enhance the overall financial health of the organisation. This creates a more sustainable business model over time.

5) Faster Delivery Times

Speed is a key advantage of Lean Methodology. By streamlining processes, organisations can deliver products faster. This meets market demands and keeps customers satisfied.

Shortened delivery times can give companies an edge over competitors. Speed also allows for quicker adaptations to changes in demand. Overall, faster execution enhances the agility of a business.

6) Enhanced Competitiveness

In today’s fast-paced market, competitiveness is crucial. Lean Methodology equips organisations with tools to stay ahead. By constantly improving and innovating, companies can differentiate themselves.

Lean practices help organisations respond better to consumer demands. A focus on quality and efficiency enhances brand reputation. This, in turn, solidifies a company’s position in the market.

Invest in a leaner and more sustainable tomorrow with our Certified Lean Foundation Course today!

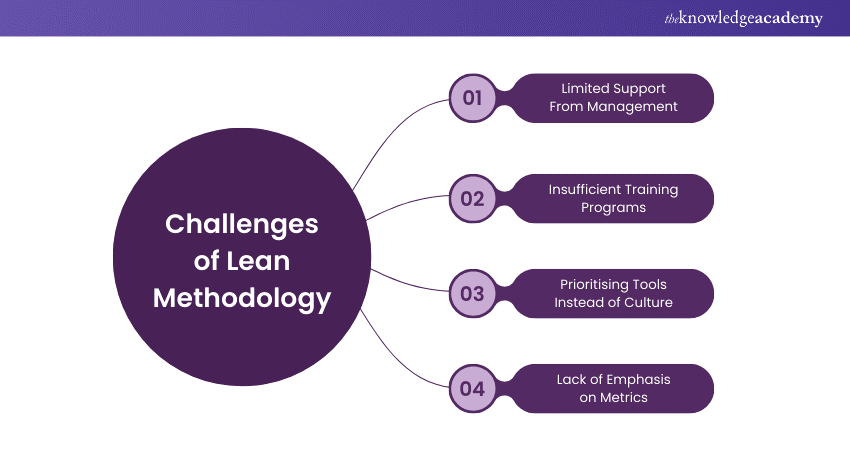

Challenges of Lean Methodology

Lean Methodology has gained popularity for its focus on efficiency and waste reduction. However, it is not without challenges. Here are some common obstacles that organisations often encounter when implementing Lean practices.

1) Limited Support From Management

A successful Lean initiative requires strong leadership. When management lacks commitment, the entire process suffers. Employees may feel unsupported and demotivated. Without backing from the top, resources may be misallocated or insufficient.

Management must lead by example, actively participating in Lean activities. Their visible commitment encourages others to follow suit. Leadership has a major impact on promoting a culture of ongoing improvement.

2) Insufficient Training Programs

Training is essential for a successful Lean implementation. Insufficient training can lead to misunderstandings of Lean principles. Employees may resort to old habits, negating potential benefits. Comprehensive training programs must cover Lean tools and concepts thoroughly.

Investing in training ensures everyone is on the same page. Without proper training, employees may become frustrated, hindering progress. Regular refreshers and advanced training sessions can enhance skills over time.

3) Prioritising Tools Instead of Culture

Many organisations mistakenly focus solely on Lean tools. However, Lean is more about culture than just techniques. Emphasising tools can lead to a superficial understanding of Lean. Organisations might adopt practices without internalising the underlying philosophy.

A strong Lean culture prioritises people, teamwork, and continuous improvement. Employees should understand why changes are necessary, not just how to execute them. Fostering a Lean mindset creates sustainable growth and development.

4) Lack of Emphasis on Metrics

Metrics play a vital role in Lean Methodology. Without proper measurement, it becomes difficult to gauge success. Many organisations skip this step, relying on subjective assessments instead. This can lead to complacency and missed opportunities for improvement.

Establishing clear, relevant metrics helps track progress effectively. Regularly reviewing metrics provides insights into operational effectiveness. Metrics should focus on customer satisfaction, process efficiency, and quality. This analytical approach drives continuous improvement and accountability.

Conclusion

Lean Methodology is more than just a set of tools; it’s a mindset. By prioritising value and minimising waste, businesses can enhance efficiency. This method promotes a culture focused on ongoing enhancements, where every team member contributes. So, take the first step by following this blog on Lean Methodology to unlock the lean principles and watch your organisation flourish.

Lean is not a destination but a journey. Allow us to be a part of your journey with our Certified Lean Practitioner Course - Join now!

Frequently Asked Questions

The 5S pillars of lean are Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardise (Seiketsu), and Sustain (Shitsuke). These pillars provide a methodology for organising, cleaning, developing, and sustaining a productive work environment.

The first rule of lean is centred on the concept of value. It encourages organisations to truly grasp the significance of value for their customers. Value is truly the cornerstone of the five lean thinking principles, and if it is lacking, the remaining four principles cannot be successfully implemented.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Lean Training , including the Introduction to Lean, Certified Lean Foundation, and Certified Lean Practitioner. These courses cater to different skill levels and provide comprehensive insights into 5 Lean Principles to Enhance Business Efficiency

Our Business Improvement Blogs cover a range of topics related to Business Improvement, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Lean Management skills. The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Introduction to Lean

Introduction to Lean

Wed 11th Dec 2024

Fri 7th Feb 2025

Fri 16th May 2025

Fri 5th Sep 2025

Fri 5th Dec 2025

Halloween sale! Upto 40% off - Grab now

Halloween sale! Upto 40% off - Grab now

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please