We may not have the course you’re looking for. If you enquire or give us a call on +31 208081674 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Quality is a fundamental to any good product or service. But how can an organisation cater do these standards and regulations? By adhering to Quality Management Protocols. ISO 9001 provided by the International Organisation for Standardisation (ISO) provides the perfect framework for you to provide the best quality of services. But do you know What is ISO 9001?

Globally, ISO 9001 is identified as one of the most widely used QMS standards equipped to address the various aspects of quality. It has more than 1.1 million certified organisations in about 170 countries, according to ISO Survey 2022. Thus, you see, it is crucial to learn about this standard, in order to comply with Quality Management protocols.

So, wait no more and read this blog on What is ISO 9001. Inthis blog you will learn everything about this standard, its Benefits of ISO 9001, requirements and much more!

Table of Contents

1) Understanding ISO 9001

2) Benefits of ISO 9001

3) Who Should use the ISO 9001 Standard?

4) What are the ISO 9001 Requirements?

5) What Topics Does ISO 9001:2015 Cover?

6) How is ISO 9001 Implemented?

7) Conclusion

Understanding ISO 9001

ISO 9001 is a globally recognised standard for Quality Management Systems (QMS), providing a framework to help organisations meet customer and regulatory requirements while enhancing customer satisfaction through effective quality management. The initial edition, based on British Standard BS 5750, placed heavy emphasis on documented procedures and quality assurance models for design, development, production, installation, and servicing. It was criticised for being overly bureaucratic and more focused on documentation than on process effectiveness.

The 2000 revision marked a significant shift towards a process-oriented approach, highlighting the importance of understanding and managing interrelated processes. It introduced a strong customer focus and emphasised continual improvement, while also promoting compatibility with other standards such as ISO 14001, thereby fostering streamlined operations and a culture of continuous improvement.

The latest revision introduced risk-based thinking, encouraging organisations to identify and address risks and opportunities. It placed greater emphasis on leadership, the context of the organisation, and adopted the High-Level Structure (HLS) to facilitate easier integration with other standards. ISO 9001 Documentation requirements were simplified, making the Quality Management System more adaptable to modern business practices.

ISO 9001 has thus evolved from a procedural focus to emphasising process orientation and risk-based thinking, making it a versatile and effective tool for improving Quality Management Systems and enhancing customer satisfaction in contemporary businesses maintaining a Business Continuity Plan.

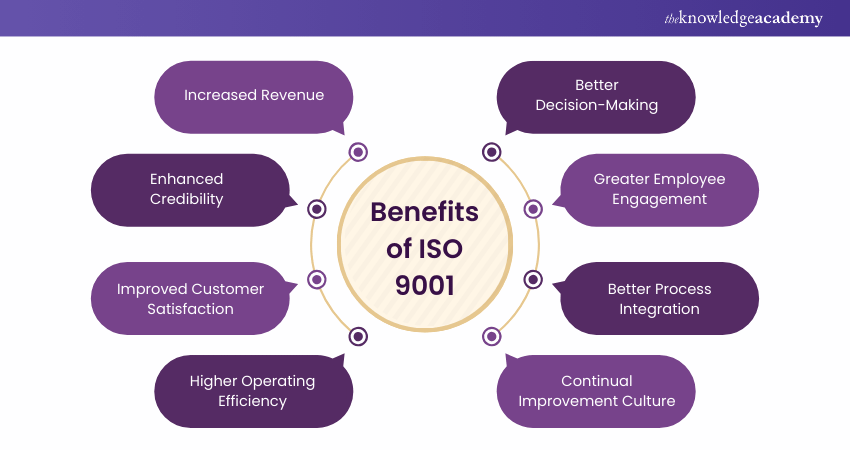

Benefits of ISO 9001

a) Increased Revenue: Leveraging the reputation of ISO 9001 can help you win more tenders and contracts. Enhanced efficiency leads to higher customer satisfaction and retention.

b) Enhanced Credibility: Many organisations, particularly in the public sector, require suppliers to have a Quality Management System based on ISO 9001, improving your credibility and appeal as a supplier.

c) Improved Customer Satisfaction: Understanding customer needs and reducing errors increases customer confidence in your ability to deliver quality products and services.

d) Higher Operating Efficiency: Following industry best practices and focusing on quality can reduce costs and streamline operations.

e) Better Decision-Making: Early detection and identification of problems allow you to take timely actions to prevent future mistakes.

f) Greater Employee Engagement: Improving internal communications ensures everyone works towards the same goals. Involving employees in process improvements boosts their happiness and productivity.

g) Better Process Integration: Examining process interactions helps identify efficiency improvements, reduce errors, and achieve cost savings.

h) Continual Improvement Culture: ISO 9001 embeds a systematic approach to identifying and exploiting opportunities for improvement, fostering a culture of continuous enhancement.

i) Better Supplier Relationships: Implementing best-practice processes contributes to more efficient supply chains, and certification signals reliability to your suppliers.

Who Should use the ISO 9001 Standard?

The ISO 9001 may be implemented by any organisation that aims to advance its Quality Management System, meet the criteria of the customers and the applicable statutory and regulatory requirements as well as increase customer satisfaction.

It is appropriate for all types of organisations, irrespective of their size and it also applies to all the sectors including manufacturing, services, healthcare, education, government, and non-governmental organisations. On top of that, ISO 9001 can be used by certification bodies or other external entities for evaluation of how an organisation complies with this International Standard.

Dissect Quality Management and its intricacies with our ISO 9001 Training. Join now!

What are the ISO 9001 Requirements?

Understanding the of ISO 9001 Requirements is crucial. The ISO 9001:2015 Standard is structured into ten sections, with the first three providing introductory information and the remaining seven outlining the requirements for a Quality Management System (QMS). The following explains the content of these seven key clauses:

1) Clause 4: Context of the Organisation

This section outlines the prerequisites for understanding your organisation to establish a QMS. It mandates identifying internal and external factors, recognising stakeholders and their expectations, delineating the QMS's scope, and pinpointing your processes and their interactions.

2) Clause 5: Leadership

The ISO 9001 Leadership Requirements emphasise the pivotal role of top management in QMS implementation. Top management is tasked with demonstrating commitment to the QMS by fostering customer focus and articulating and disseminating the quality policy.

3) Clause 6: Planning

Top management must strategies for the sustained operation of the QMS. This entails assessing risks and opportunities within the organisation’s QMS, establishing quality objectives for enhancement, and developing plans to achieve these objectives.

4) Clause 7: Support

This section addresses the management of all resources critical to the QMS. It includes governing various resources, such as human resources, infrastructure, the work environment, monitoring and measurement tools, and organisational knowledge. It also covers requirements related to competence, awareness, communication, and control of documented information.

5) Clause 8: Operation

The operational requirements encompass all phases of product or service planning and creation. This section covers planning, reviewing product requirements, design, supervision of external suppliers, development and release of products or services, and managing nonconforming process outputs.

6) Clause 9: Performance Evaluation

This section outlines the prerequisites for ensuring the effective functioning of your QMS. It involves monitoring and measuring processes, evaluating customer satisfaction, conducting internal audits, and performing ISO 9001 Audits.

7) Clause 10: Improvement

The final section encompasses the prerequisites for enhancing your QMS over time. This includes evaluating process nonconformities and taking corrective actions. These sections adhere to the Plan-Do-Check-Act cycle, leveraging these elements to facilitate change within the organisation’s processes, driving and sustaining improvements.

Enhance your auditing skills and ensure quality compliance with our ISO 9001 Internal Auditor Training – sign up now!

What Topics Does ISO 9001:2015 Cover?

ISO 9001:2015 provides a framework for establishing, implementing, maintaining, and improving a Quality Management System (QMS) based on ISO 9001 Principles. It covers the following key topics:

1) Context of the Organisation: Identifying internal and external factors, stakeholder needs, the QMS scope, and process interactions.

2) Leadership: Top management’s commitment, establishing and communicating the quality policy, and defining roles and responsibilities.

3) Planning: Addressing risks and opportunities, setting quality objectives, and planning for changes.

4) Support: Managing resources, ensuring personnel competence, raising awareness, establishing effective communication, and controlling documented information.

5) Operation: Planning and controlling processes, determining and reviewing customer requirements, managing design and development, controlling external providers, ensuring product and service quality, and handling nonconformities.

6) Performance Evaluation: Monitoring and measuring QMS performance, conducting internal audits, and reviewing the system’s effectiveness through management reviews.

7) Improvement: Continually enhancing the QMS, addressing nonconformities, taking corrective actions, and driving overall performance improvement.

How is ISO 9001 Implementated?

Implementing ISO 9001 involves several structured steps to ensure effective results. The first crucial step is identifying the purpose of getting accredited. This helps engage all members of the organisation and raises awareness of the commitment to quality.

Next, confirm the requirements with a copy of ISO Quality Standards to serve as a basis for specific legislation. Formally define the quality policy and objectives in a document as per ISO 9001 Standards. This standardisation helps measure and monitor progress effectively.

After completing your paperwork and establishing processes, you need to install ISO 9001 before certification. To ensure successful certification, your organisation must take the following actions:

Internal Audit

Conduct an ISO 9001 Internal Audit to examine your QMS procedures. The goal is to ensure records are in place to verify adherence to procedures and identify potential issues. For example, an internal audit might reveal inconsistencies in how quality checks are documented across different departments.

Management Review

Perform a formal assessment of the management system procedures by the management team. This involves analysing pertinent data, making informed decisions, and allocating resources. For instance, a management review might uncover the need for additional training resources to improve employee competence.

Corrective Actions

Address the underlying causes of any issues found during the internal audit and management review. Document your process for resolving these issues to ensure compliance with the ISO 9001 Audit Checklist. For example, if the audit reveals a gap in supplier Quality Management, corrective actions might include revising supplier evaluation criteria and processes.

Looking to enhance your expertise in Qquality Mmanagement? Register in our comprehensive ISO 9001 Course today!

Conclusion

We hope this blog helped you understand What is ISO 9001 and how you can implement it in your organisation. Additionally, this blog also presented and discussed its seven principles and benefits, including the difference between ISO 9001 and 13485. Deploying a Quality Management System is a necessity as it’ll streamline processes, cut excess costs, and enhance the quality of your products and services.

Do you wish to improve the quality of products and services of your organisation? Then, consider attending ISO 9001 Training right away!

Frequently Asked Questions

What is the Current ISO 9001 Standard?

The current ISO 9001 standard is ISO 9001:2015. It provides a framework For Quality Management Systems, emphasising risk-based thinking, process orientation, and continuous improvement to ensure consistent quality in products and services.

What is ISO 9001 Certification and Does my Organisation need to get certified?

ISO 9001 Certification demonstrates an organisation's adherence to the ISO 9001 standard. While not mandatory, certification can enhance credibility, improve efficiency, and increase customer satisfaction, making it beneficial for organisations seeking to enhance their Quality Management Systems.

What are the Other Resources and Offers Provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is The Knowledge Pass, and How Does it Work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are the Related Courses and Blogs Provided by The Knowledge Academy?

The Knowledge Academy offers various ISO Certification Courses, including Integrated Management System Training, Certified Internal Auditor Training and ISO 56002 Innovation Management System Training courses. These courses cater to different skill levels, providing comprehensive insights into ISO 9001 Principles.

Our ISO & Compliance Blogs covers a range of topics offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Business Improvement skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

ISO 9001 Foundation course

ISO 9001 Foundation course

Mon 17th Feb 2025

Mon 3rd Mar 2025

Mon 7th Apr 2025

Mon 12th May 2025

Mon 2nd Jun 2025

Mon 7th Jul 2025

Mon 4th Aug 2025

Mon 1st Sep 2025

Mon 20th Oct 2025

Mon 10th Nov 2025

Mon 1st Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please