We may not have the course you’re looking for. If you enquire or give us a call on +31 208081674 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Organisations are always striving to improve their business processes, reduce waste, and enhance customer satisfaction. Thus, it is vital for them to understand the difference between Lean vs Six Sigma, two popular methodologies significantly recognised by companies in the pursuit of progress.

While these approaches share the common goal of streamlining operations and improving overall performance, they have distinct levels of principles, tools, and applications. While Lean focuses on minimising waste and enhancing process flow, Six Sigma focuses on reducing defects and process variation. However, there is more to understand about their differences.

This blog will help you to learn the difference between Lean vs Six Sigma, which describes a systematic approach to eliminating waste from organisational systems.

Table of Contents

1) What is Lean?

2) What is Six Sigma?

3) Key Difference Between Lean and Six Sigma

4) Lean vs. Six Sigma: Which methodology is a better option for you?

5) Conclusion

What is Lean?

Lean, also widely known as ‘Lean Manufacturing’ or ‘Lean Thinking’, is a management methodology that originated in the automotive industry. It was further popularised by Toyota as the Toyota Production System.

It focuses on maximising customer value while minimising waste, ultimately improving efficiency and reducing costs. Lean principles and techniques have since been adopted by various industries worldwide, revolutionising the ways in which organisations approach Process Improvement.

Now, the core principle of Lean is to identify and eliminate waste, which refers to any activity or process that is not valuable from the customer’s perspective. Organisations can streamline their operations and eliminate waste, thus significantly improving productivity, quality, and customer satisfaction.

Lean practitioners use value stream mapping, which is a visual representation of the entire stream of the value to identify areas of waste, bottlenecks, and inefficiencies. This identification allows them to pinpoint specific areas for improvement and prioritise their efforts.

Additionally, Lean emphasises the importance of flow, which refers to the uninterrupted movement of work through a process. Organisations can eliminate barriers and bottlenecks and thus improve cycle times, reduce lead times, and increase overall process efficiency. The last and ultimate goal is to create a seamless flow of work from start to finish, minimising delays and waiting times.

Moreover, Lean also promotes the concept of pull, a demand-driven system in which products or services are produced only when needed. Organisations can strive to avoid overproduction and excess inventory, thus reducing costs, minimising waste, and responding immediately to customer demand.

The lean methodology identifies seven waste categories common across most production systems. Here is a brief look at the list of the seven categories:

1) Overproduction: Overproduction occurs when unwanted products are made.

2) Waiting: Waiting refers to the duration of lag between each production stage.

3) Transport: Transport occurs due to the inefficient movement of materials or products.

4) Motion: Motion is caused by poor work standards and inefficient movement of employees during tasks.

5) Over-processing: Over-processing involves spending excess time producing products in an inefficient fashion.

6) Inventory: Inventory refers to inventory levels crossing their capacity, leading to work overload.

7) Defects: Defects are the number of times employees spend identifying and tackling production errors.

What is Six Sigma?

Six Sigma is a data-driven methodology and management philosophy that focuses on reducing defects and helps in process variation. The concept aims to improve quality, efficiency, and customer satisfaction. It was developed by Motorola in the 1980s and gained widespread recognition and adoption across industries by acting as a powerful tool to improve processes and solve problems.

Organisations need to understand How Six Sigma Works to achieve near-perfection by systematically identifying and eliminating sources of variation and defects.The term “Six Sigma” refers to a statistical measure that represents a level of quality where the probability of a defect occurring is extremely low, with approximately 3.4 defects per million opportunities.

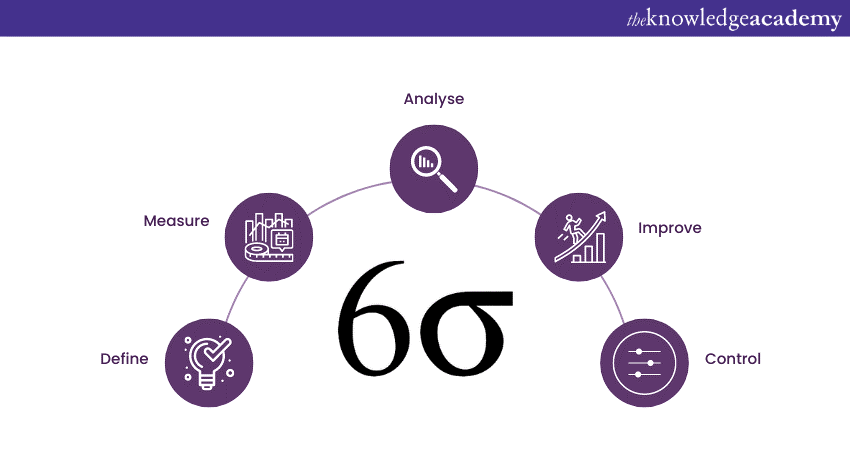

Six Sigma follows a structured problem-solving approach known as ‘DMAIC’, which stands for Define, Measure, Analyse, Improve, and Control. This methodology provides a systematic framework for tackling Process Improvement projects, including the following:

1) Define: This stage clearly defines the problem or opportunity for improvement and establishes project goals. It involves understanding customer requirements and expectations.

2) Measure: It collects and analyse data to measure the ongoing performance of the process and identify areas for improvement. This step involves identifying key process metrics and establishing a baseline.

3) Analyse: It conducts in-depth data analysis to identify the root causes of defects and variation. Statistical tools and techniques are employed to understand the relationship between process inputs and outputs.

4) Improve: It Implements solutions to address the identified root causes and improve process performance. This stage focuses on testing and implementing process changes that lead to significant improvement.

5) Control: It establishes control and monitoring systems to sustain the improvements over time. Control plans are developed to ensure that the improved process remains stable and continues to deliver the desired results.

Implement Lean Six Sigma principles by signing up for the DMAIC Training now!

Key Differences Between Lean and Six Sigma

To better understand how these methodologies compare, it's important to explore their unique approaches and applications. The table below highlights the Key Differences Between Lean and Six Sigma:

1) Objectives

a) Lean: Aims to improve efficiency, speed, and customer value by eliminating waste.

b) Six Sigma: Focuses on enhancing quality, reducing defects, and increasing customer satisfaction.

2) Methodologies

a) Lean: It employs tools like value stream mapping, Kanban, 5S, and Kaizen events to streamline processes.

b) Six Sigma: It utilises a structured approach (DMAIC) and statistical analysis to identify and easily eliminate root causes of defects.

3) Scope

a) Lean: It is applicable to entire value streams or processes.

b) Six Sigma: It is often used for specific projects or problem-solving initiatives.

4) Mindset

a) Lean: It emphasises continuous improvement and teamwork to achieve efficiency gains.

b) Six Sigma: It promotes a data-driven approach and structured problem-solving to minimise variation.

5) Culture

a) Lean: It encourages employee involvement and empowerment to drive process improvements.

b) Six Sigma: It focuses on data and statistical analysis to make informed decisions.

Elevate your skills with Six Sigma qualification- Join our Six Sigma Yellow Belt Course today!

Lean vs Six Sigma: Which Methodology is Better

Lean and Six Sigma are distinct methodologies, each serving unique purposes. Below are key points highlighting their differences and the benefits of combining them:

1) Lean Methodology: It is ideal for companies who are looking for a simple and iterative framework to drive growth and improvement.

2) Six Sigma Methodology: It is best suited for organisations that aim to minimise unpredictability and enhance efficiency in complex corporate environments.

3) Lean Six Sigma: It is a hybrid method that combines Lean and Six Sigma to leverage the strengths of both frameworks.

4) Cost and Waste Reduction: It helps implementing Lean Six Sigma effectively reduce costs and waste within an organisation.

5) Operational and Quality Improvement: This hybrid framework helps improve operational processes and the quality of outputs.

6) Customisable Approach: Companies can seamlessly tailor their framework by combining both methodologies to achieve long-term benefits.

Lead the transformative change as a certified Six Sigma professional with our Six Sigma Black Belt Course – Sign up now!

Conclusion

This blog has discussed the difference between Lean Vs Six Sigma. These are two powerful methodologies that improve processes through their distinct approaches to improvement.By employing a methodology that is suitable for their needs, organisations can achieve comprehensive and sustainable improvements in their operations. Consequently, they can drive a competitive advantage in today’s dynamic business environment.

Drive enterprise-wide improvements with our advanced Six Sigma Black Belt Upgrade Course - join today!

Frequently Asked Questions

Yes, Six Sigma is still in high demand. It remains a valuable methodology for process improvement, quality control, and operational efficiency. Many industries today, including manufacturing, healthcare, and finance, are employing Six Sigma-certified professionals to optimise their business performance and drive long-term success.

Yes, you can use Lean and Six Sigma together. It is a profitable prospect for businesses often called Lean Six Sigma. The approach merges Lean's focus on eliminating waste with Six Sigma's emphasis on reducing variability. Together, they work to drive process efficiency, improve quality, and deliver greater value to organisations.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Six Sigma Certification Training, including Six Sigma Green Belt, Six Sigma Yellow Belt, and DMAIC Training. These courses cater to different skill levels, providing comprehensive insights into the Six Sigma Career Path.

Our Business Improvement Blogs cover a range of topics related to Process Management, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Lean Six Sigma skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Lean Six Sigma Green Belt

Lean Six Sigma Green Belt

Mon 6th Jan 2025

Mon 13th Jan 2025

Mon 20th Jan 2025

Mon 27th Jan 2025

Mon 3rd Feb 2025

Mon 10th Feb 2025

Mon 17th Feb 2025

Mon 24th Feb 2025

Mon 3rd Mar 2025

Mon 10th Mar 2025

Mon 17th Mar 2025

Mon 24th Mar 2025

Mon 31st Mar 2025

Mon 7th Apr 2025

Mon 14th Apr 2025

Tue 22nd Apr 2025

Mon 28th Apr 2025

Tue 6th May 2025

Mon 12th May 2025

Mon 19th May 2025

Tue 27th May 2025

Mon 2nd Jun 2025

Mon 9th Jun 2025

Mon 16th Jun 2025

Mon 23rd Jun 2025

Mon 30th Jun 2025

Mon 7th Jul 2025

Mon 14th Jul 2025

Mon 21st Jul 2025

Mon 28th Jul 2025

Mon 4th Aug 2025

Mon 11th Aug 2025

Mon 18th Aug 2025

Tue 26th Aug 2025

Mon 1st Sep 2025

Mon 8th Sep 2025

Mon 15th Sep 2025

Mon 22nd Sep 2025

Mon 29th Sep 2025

Mon 6th Oct 2025

Mon 13th Oct 2025

Mon 20th Oct 2025

Mon 27th Oct 2025

Mon 3rd Nov 2025

Mon 10th Nov 2025

Mon 17th Nov 2025

Mon 24th Nov 2025

Mon 1st Dec 2025

Mon 8th Dec 2025

Mon 15th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please