We may not have the course you’re looking for. If you enquire or give us a call on +48 221041849 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Manual Handling is a term many might hear frequently in workplaces, but its significance often goes unnoticed until someone gets hurt. At its core, Manual Handling encompasses any activity where force exerted by a person is used to lift, lower, push, pull, carry, or shift, hold, or restrain any object. Yet, how often do we stop to consider if we're employing the right Manual Handling Techniques?

These techniques aren't just a set of guidelines; they form the backbone of safe and efficient operations in diverse settings. When practised correctly, they drastically reduce the risk of injuries and ensure tasks are executed more efficiently. Want to know how? Read this blog to learn about essential Manual Handling Techniques. Also, cover how these handling techniques help implement safety implications.

Table of contents

1) Why proper Manual Handling is essential?

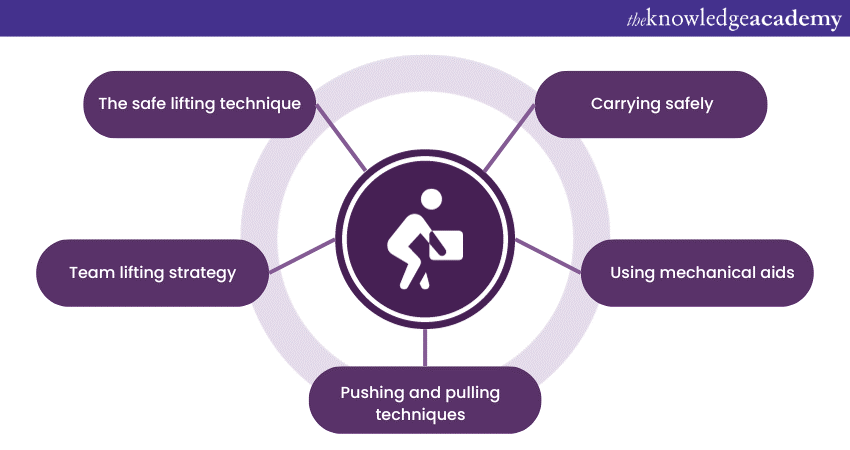

2) Five safe Manual Handling Techniques

a) The safe lifting technique

b) Team lifting strategy

c) Pushing and pulling techniques

d) Carrying safely

e) Using mechanical aids

3) Conclusion

Why Proper Manual Handling is essential?

Let us go over some features that will indicate why good Manual Handling is crucial:

a) Injury prevention: The foremost reason to employ correct Manual Handling Techniques is to prevent injuries. Improper methods can lead to strains, sprains, and more severe musculoskeletal disorders. The spine and back are especially vulnerable, with incorrect lifting being a common cause of back injuries.

b) Economic implications: Work-related injuries from improper Manual Handling lead to absenteeism and reduced productivity. There's also the potential for increased medical and insurance costs for businesses. This can result in effective training, a cost-saving measure in the long run.

c) Legal obligations: In many regions, employers are legally bound to ensure that employees are trained in and practice safe Manual Handling Techniques. Non-compliance can lead to legal repercussions, fines, and a damaged reputation.

d) Enhanced productivity: Proper techniques often mean tasks are completed more efficiently. When workers know the best way to lift, carry, or move items, they do it faster and with less hesitation.

e) Worker morale: A safe environment boosts worker morale. When employees feel their well-being is a priority, it improves job satisfaction, reduces turnover, and fosters a positive workplace culture.

f) Long-term health: Regular exposure to incorrect Manual Handling can lead to chronic ailments. Proper techniques ensure employees' long-term health and well-being, preventing conditions that might affect their quality of life beyond the workplace.

g) Adaptable skills: Proper Manual Handling Techniques, once learned, are skills that employees can take with them across different jobs and into daily life, promoting overall safety and well-being.

Master the art of safe Manual Handling; sign up for our Manual Handling At Work Training now!

Five safe Manual Handling Techniques

Let us look at five safe Manual Handling Techniques to ensure safety at the workplace when engaging in Manual Handling activities:

The safe lifting technique

Some of the key components and practices of safe lifting technique involves the following:

a) Preparation is key: Before you lift, clear your path and ensure the destination area is ready to receive the item. This reduces the need for unnecessary adjustments or movements with the load.

b) Assess the load: Always gauge the weight by trying to gently move or lift a corner before fully committing. If it feels too heavy, get help or use an assisting tool.

c) Proper foot position: Stand with your feet shoulder-width apart, giving a stable base of support. One foot can be slightly in front of the other to improve balance.

d) Get close: Stand as close as possible to the load. This reduces the strain on the back and arms and helps maintain your centre of gravity.

e) Bend at the knees, not the waist: When getting ready to lift, bend your knees and keep your back straight. This technique utilises the strong leg muscles and reduces pressure on the back.

f) Tighten your core: Engaging your core muscles provides added support to the back during the lift.

g) Firm grip: Ensure both hands have a secure and comfortable grip on the item. This minimises the risk of the object slipping and causing an injury.

h) Lift smoothly: Use your leg muscles, the strongest muscles in your body, to push upwards. Keep the movement steady and avoid any jerking motions.

i) Keep load close: Hold the item close to your body, preferably near waist level. This decreases the strain on the back and makes the load feel lighter.

j) Look ahead: Keep your neck and head in a neutral position. Look straight ahead, not up or down, to prevent neck strain.

k) Avoid twisting: If you need to turn, move your feet so your entire body turns instead of twisting your back.

Team lifting strategy

Some of the key components and practices of team lifting strategy involves the following:

a) Communication is crucial: Before lifting, establish a clear line of communication between team members. Deciding who will lead and who will follow ensures both are on the same page throughout the process.

b) Equal weight distribution: Ensure the object's weight is equally distributed between the lifters. This might mean adjusting hand or grip positions to maintain balance.

c) Unified timing: The lift should be synchronised. Use a simple countdown ("3, 2, 1, lift") to make sure both individuals lift and lower simultaneously. This can prevent uneven force application.

d) Foot positioning: Team members should maintain similar foot stances, providing stability and reducing the chances of stumbling or imbalance.

e) Maintain close proximity: Just as in individual lifting, the object should be kept close to the body, ensuring minimal strain on the back and arms.

f) Assign roles: One person can act as the guide, navigating the route and watching for obstacles, while the other ensures the load remains stable.

g) Regular rest breaks: For extended carries, plan for short breaks to adjust grip, change leading roles, or simply rest to prevent fatigue.

h) Use support tools: Employing lifting belts or straps can provide additional support and further distribute the weight.

i) Training together: It's beneficial for team members to train together, understanding each other's strengths and limitations. This can ensure a more cohesive lifting strategy.

Create a work culture that prioritises health and safety; sign up for our Health & Safety in the Workplace Training now!

Pushing and pulling techniques

Some of the key components and practices of pushing and pulling techniques involves= the following:

a) Evaluate the task: Before pushing or pulling, assess the weight and dimensions of the object, as well as the distance and path you'll be moving it over. Check for obstacles and potential hazards.

b) Footwear matters: Wear shoes with good grip and support. Proper footwear provides stability and reduces the risk of slipping, especially when exerting force.

c) Positioning: Whenever possible, push rather than pull. Pushing allows better weight distribution, visibility, and control over the object.

d) Stable stance: Keep feet at least shoulder-width apart, providing a firm base of support when applying force.

e) Engage the core: Tightening your core muscles offers added support, reducing the strain on the back.

f) Use body weight: Lean into the object when pushing, utilising your body weight for momentum. When pulling, use a controlled step backwards, aligning the movement with the pull.

g) Maintain a straight back: Whether pushing or pulling, keep the back straight and the head up. This posture helps distribute force more evenly and reduces the risk of injury.

h) Adjustable grip: Use both hands and adjust your grip as necessary for maximum control and force distribution.

i) Smooth movements: Avoid jerky motions. Instead, aim for a consistent, smooth application of force, making the task more manageable and reducing the risk of muscle strain.

j) Regularly check equipment: If using carts, trolleys, or other equipment, ensure they are in good working order, with functioning wheels and no obstructions.

Carrying safely

Some of the key components and practices of carrying safely technique involves the following:

a) Preliminary assessment: Before carrying any object, gauge its weight and shape. Ensure that you can maintain a firm grip throughout the transportation process.

b) Clear path: Prioritise a clear, obstacle-free route. Check the path for potential hazards, such as wet floors, cords, or clutter, that could cause trips or falls.

c) Two-handed grip: Use both hands to distribute the weight evenly whenever possible. This ensures a secure hold and better balance.

d) Close to the body: Keep the object as close to your body as possible, ideally around waist level. This reduces the strain on your back and arms.

e) Steady pace: Move at a consistent, unhurried pace. Rapid or erratic movements can cause instability or increase the risk of injury.

f) Regular breaks: For longer distances, take frequent breaks. This helps to alleviate muscle fatigue and gives a moment to readjust the grip if needed.

g) Maintain visibility: Ensure that the carried object does not obstruct your vision. If you can't see over or around the item, ask for assistance or use mirrors to navigate.

h) Even distribution: If carrying two or more items, try to balance the weight evenly between both hands.

i) Avoid twisting: Just like lifting, move your entire body instead of twisting at the waist when turning.

j) Safe setting down: Use the principles of safe lifting in reverse when setting the object down. Bend the knees, keep the back straight, and lower the item gently.

Using mechanical aids

Some of the key components and practices while using mechanical aids involves the following:

a) Assess the need: Before resorting to Manual Handling, evaluate if a mechanical aid could be employed. These devices are designed to handle specific weights, sizes, and types of objects.

b) Proper training: Ensure all users receive comprehensive training on the chosen mechanical aid. Understanding its functions, capabilities, and limitations is paramount.

c) Regular maintenance: Consistently check and maintain mechanical aids. Ensuring they are in good working condition reduces the risk of malfunctions that could lead to accidents or injuries.

d) Choose the right tool: From trolleys and wheelbarrows to forklifts and hoists, select the mechanical aid best suited for the specific task.

e) Safety features: It is important to ensure that all safety features, including brakes, guards, and alarms, are working properly. These features play a critical role in preventing accidents.

f) Clear pathways: Just as with manual carrying, ensure the route is clear of obstructions. This is especially important for larger aids like forklifts, which require more space to manoeuvre.

g) Load stability: When using the aid, ensure the load is stable. Items should be evenly distributed and, if necessary, secured to prevent shifting or falling.

h) Limit overloading: Never exceed the weight capacity of the mechanical aid. Overloading can lead to equipment failure or compromise control.

i) Stay alert: Even when using mechanical aids, remain aware of your surroundings. Monitor other nearby individuals, ensuring they are safe and informed of your actions.

j)Storage: After use, store mechanical aids in their designated areas. This prolongs their lifespan and ensures they are readily available and in good condition for subsequent use.

Conclusion

Proper Manual Handling Techniques are indispensable in ensuring safety and efficiency in various tasks, whether lifting, carrying, or using mechanical aids. By prioritising these methods and continuously updating our knowledge and skills, we protect our physical well-being and contribute to a more productive and accident-free environment.

Learn the proper use of protective equipment for working at height; sign up for our Working At Height Training now!

Frequently Asked Questions

Upcoming Health & Safety Resources Batches & Dates

Date

Manual Handling at Work

Manual Handling at Work

Fri 24th Jan 2025

Fri 28th Mar 2025

Fri 23rd May 2025

Fri 25th Jul 2025

Fri 26th Sep 2025

Fri 28th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please