We may not have the course you’re looking for. If you enquire or give us a call on +0800 780004 and speak to our training experts, we may still be able to help with your training requirements.

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

ISO 9001 is a worldwide known standard Quality Management System (QMS). It gives the foundation for the organisations to set up and manage the required quality management methodologies that promote added client's satisfaction and ultimately, business development. ISO 9001 adherence involves detailed documenting of the work processes, procedures and records.

The implemented documentation requirements of ISO 9001 Audit are the keys to consistency, traceability and the never-ending improvement within the QMS of an organisation. This ranges from the archive of documents and records that help us to describe exhaustively, rule, and measure the processes which have influence on product and service quality. In this blog, you will go through a comprehensive overview of QMS through understanding ISO documentation requirements, which deals with relevant guidelines and principles.

Table of Contents

1) Documentation in ISO 9001

2) Types of ISO 9001 Documents

3) ISO 9001 Documentation Requirements

4) Examples Of Non-Mandatory Documented Information To Be Maintained:

5) Conclusion

Documentation in ISO 9001

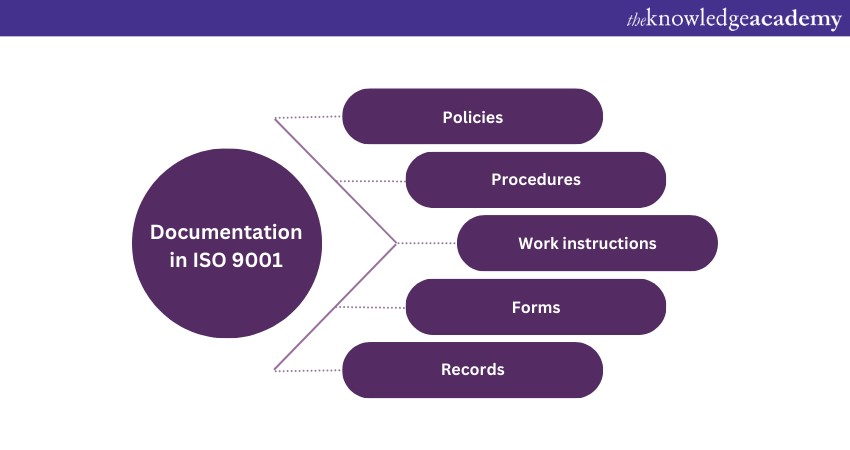

The documentation of ISO 9001 denotes the obligatory master records, documents that organisations must create, maintain, and incorporate so as to ensure and sustain a QMS that is ISO 9001 compliant and effective. These records take one of the main places in the document formation concerned with products' and services' quality determination, organisation and improvement. ISO 9001 documentation consists of a wide array of materials, including:

a) Policies: These top-level ISO 9001 Principles declare the organisation's dedication to quality and serve as a roadmap for QMS implementation.

b) Procedures: Intricate, sequential instructions give the flow of how different organisational tasks will be carried out.

c) Work instructions: Work instructions, unlike procedures, are much more task-specific and cover a wide range of tasks, providing step-by-step guidance with, as applicable, graphics, illustrations, and checklists.

d) Forms: Documents used to accumulate data, including daily reports, customer satisfaction forms or maintenance logs.

e) Records: Primary documents that verify requirements or outcomes of monitoring activities, such as Audit Reports, ISO 9001 Audit Checklist, corrective action assessments, or main meeting minutes.

f) Risk assessment and management documentation: Risk-based thinking, which the ISO 9001:2015 Clause 6.1 exhaustively talks about, should be documented. This should be about identifying, assessing and managing risks.

Types of ISO 9001 Documents

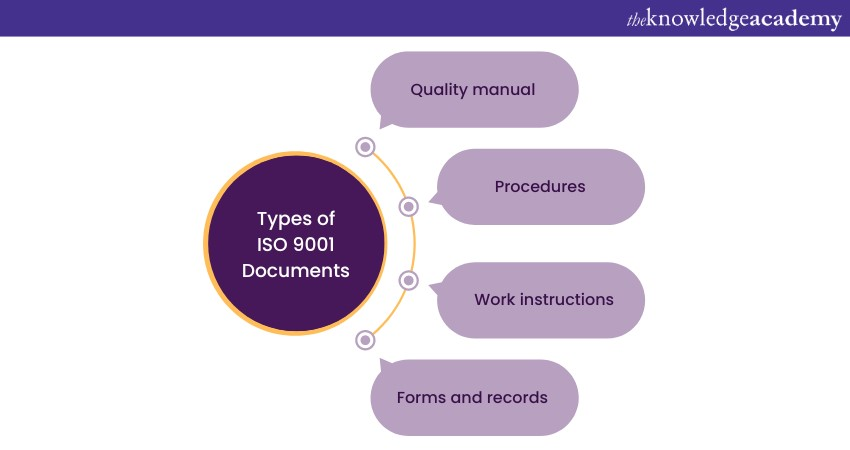

ISO 9001 Documentation encompasses a variety of document types, each serving a distinct role within the Quality Management Systems (QMS). Understanding these types is crucial for effectively implementing the Benefits of ISO 9001 and maintaining ISO 9001 compliance. Here's an in-depth look at each:

a) Quality manual: The Quality manual is a principal part of ISO 9001 Documentation process. It is an umbrella over the organisation QMS particularly. In this document, we define QMS through the scope and interaction of its processes and show the organisation's readiness to meet the ISO 9001 Requirements. However, ISO 9001 does not require QA and Quality Manual anymore as many companies are still using the latter as a generalised overview.

b) Procedures: In this case, processes mean the detailed, step-by-step instructions that define the way different processes within the organisation must be implemented. They have a systematic approach toward carrying things out to standard and make sure that they are done consistently to ISO 9001 Requirement. Routines may involve requirements for input, processes, responsibilities, and output measurements.

c) Work instructions: Work instructions focus even more than procedures on specialised job activities, with precise guidelines for a particular task or operation. These could range from visual aids, checklists, as well as procedures detailing task implementation, for instance precision or specialist tasks.

d) Forms and records: These documents serve as channels through which data is collected, including inspection records, customer feedback forms, or maintenance logs. On the contrary, documentation will show compliance to control processes or information from the monitoring and surveillance. Documents include the audit, corrective action, and management review records such as meeting minutes.

Learn the layout standards that follow the PDCA cycle. Sign up for our ISO 9001 Lead Auditor Training now!

ISO 9001 mandatory documents and records

ISO 9001, the international standard that places a mandatory documentation requirement that must be followed by organisations to properly implement and maintain their Quality Management Systems (QMS). These documentation requirements are quite important for guaranteeing internal uniformity, accountability and further compliance with ISO 9001 norms. Here is an overview of the primary ISO 9001 Documentation requirements as mentioned below:

Quality Policy (Clause 5.2.1a)

One of the essential documents professional organisations are required to have and abide by is their quality policy. The policy, in turn, should express this quality objective and the organisation's readiness to achieve the set ISO Quality Standards. It outlines the framework and represents the basic philosophy of the QMS.

Quality Objectives (Clause 6.2.1):

ISO 9001 requires organisations to implement quality objectives after setting and documenting them in a manner that is related to the organisation's mission and the strategic direction. Such goals should be quantifiable, coincide with the quality policy, and supply a way for the performance improvement.

Scope of the QMS (Clause 4.3)

Organisations are required to include, in the QMS chart, the scope that covers their system. This paper sets limits and coverage of the QMS within an organisation that is to be included in product, service and location specified.

Documented Information (Clause 7.5.3)

ISO 9001 ISO requires organisations to ensure that documented information necessary to support processes is being effectively planned, operated as well as controlled. In addition to these, documented procedures, work instructions, forms, records and other important documents that must be there, will be there.

Control of Documents (Clause 7.5.3)

The Companies involved would have a well-organised procedure of controlling the development, approval, review, release, and access of such documents necessary for the QMS. These are the processes which make sure everything is up-to-date, and available for those authorised to see them.

Control of Records (Clause 7.5.3)

ISO 9001 calls upon businesses for the establishment of and maintenance of procedures linked to the identification, storage, protection, retrieval, retention, and elimination of records. Evidence, for example, financial reports, noncompliance records and management review records reflect the status of the QMS.

Operational Control (Clause 8.1)

Organisations should file data that enables them to carefully plan their processes, manage and control them in a systematic manner. In addition, it may require different types of work instructions, process flowcharts and records of process parameters.

Monitoring and Measurement (Clause 9.1)

Organisations need to implement control and measuring procedures for features and quality. This documentation ensures that measurements are carried out in a consistent manner and results are reported faithfully.

Internal Audits (Clause 9.2)

With respect to the requirements of the ISO 9001 in organisations, they are supposed to apply documentation to their ISO 9001 internal audit program and procedures. Moreover, it involves audit schedules, checklist, and audit documents.

Control of Nonconforming Product (Clause 8.7)

The documentation of methods for dealing with the unnecessary products is advised. This mandates that all nonconformities are adequately captured, recorded, and rectified.

Management Review (Clause 9.3)

Organisations are advised to deposit details such as the agenda, minutes, and action items of the management review. They prove that the organisation is on the focus of the continuous improvement.

Competence and Training (Clause 7.2)

Although not expressly mentioned in ISO 9001, many organisations do write their procedures on staff training and competence. Such data will be accumulated, for example, personnel qualifications records, training plans, and training records. Ensuring that staff undergo ISO 9001 Training can be an integral part of maintaining and improving these records.

Achieve Operational Excellence! Get your free copy of the ISO 9001:2015 Standard PDF and discover best practices for streamlined processes and improved product quality.

Examples of non-mandatory documented information to be maintained:

1) Procedure for determining context of the organisation and interested parties (Clauses 4.1 and 4.2)

2) Procedure for addressing risks and opportunities (Clause 6.1)

3) Procedure for competence, training and awareness (Clauses 7.1.2, 7.2 and 7.3)

4) Procedure for equipment maintenance and measuring equipment (Clause 7.1.5)

5) Procedure for document and record control (Clause 7.5)

6) Procedure for sales (Clause 8.2)

7) Procedure for design and development (Clause 8.3)

8) Procedure for production and service provision (Clause 8.5)

9) Procedure for management of nonconformities and corrective actions (Clauses 8.7 and 10.2)

10) Procedure for monitoring customer satisfaction (Clause 9.1.2)

11) Procedure for internal audit (Clause 9.2)

12) Procedure for management review (Clause 9.3)

Need a guide for implementing ISO 9001? Download the ISO 9001 Procedures PDF today and start enhancing your business operations with best practices.

Conclusion

ISO 9001 Documentation is not just paperwork; it's the lifeline of a robust Quality Management Systems (QMS). It ensures consistency, fosters compliance, and fuels continuous improvement. These are the core ISO 9001 documentation requirements. However, organisations should customize their documentation to suit their specific needs, industry standards, and the complexity of their processes while ensuring alignment with ISO 9001 Standards.

Gain skills in implementing quality management to achieve organisational goals. Sign up for our ISO 9001 Lead Implementer Training now!

Frequently Asked Questions

How do I write a QMS document?

Define scope, objectives, structure. Gather data, write clear content. Ensure compliance, consistency. Include visual aids, examples. Review, revise, approve. Control documents, distribute, train, implement. Monitor, improve continuously.

What are ISO controlled documents?

ISO controlled documents are managed according to ISO standards (e.g., ISO 9001). They include policies, procedures, and records essential for quality management. These documents undergo strict version control, distribution, and access management to ensure integrity and compliance.

What are the other resources and offers provided by The Knowledge Academy?

The Knowledge Academy takes global learning to new heights, offering over 3,000 online courses across 490+ locations in 190+ countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

What is the Knowledge Pass, and how does it work?

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

What are related courses and blogs provided by The Knowledge Academy?

The Knowledge Academy offers various ISO 9001 Certification Courses, including ISO 9001 Foundation Course, ISO 9001 Lead Auditor Course and ISO 9001 Internal Auditor Course. These courses cater to different skill levels, providing comprehensive insights into ISO 9001 Documentation Requirement.

Our Business Improvement Blogs covers a range of topics offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Business Improvement skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

ISO 9001 Foundation course

ISO 9001 Foundation course

Mon 7th Apr 2025

Mon 12th May 2025

Mon 2nd Jun 2025

Mon 7th Jul 2025

Mon 4th Aug 2025

Mon 1st Sep 2025

Mon 20th Oct 2025

Mon 10th Nov 2025

Mon 1st Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please