We may not have the course you’re looking for. If you enquire or give us a call on +0800 780004 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Kaizen Methodology, derived from the Japanese word for "continuous improvement," is a powerful approach that has revolutionised numerous industries. Originating from post-World War II Japan, Kaizen has become a globally recognised practice for driving incremental and sustainable improvements in processes and systems.

If you wish to learn about the Kaizen Methodology, its core ideas, advantages, and how to implement them, read this blog to get a comprehensive understanding. This blog will help you learn its core principles, key elements, and practical implementation strategies. Join us as we iterate how Kaizen can enhance efficiency and foster a culture of continuous improvement within your organisation. Explore the core principles of the Kaizen Methodology, understand its key elements, and learn how to implement this proven approach for continuous improvement.

Table of Contents

1) What is Kaizen Methodology?

2) Key elements of Kaizen Methodology

3) Implementing Kaizen in practice

4) Why implement the Kaizen Method?

5) Conclusion

What is Kaizen Methodology?

Kaizen, derived from the Japanese language, means "change for the better" or "continuous improvement." It embodies core principles such as gradual improvement and employee involvement. Kaizen emphasises the power of small, incremental changes to drive significant progress. Rather than seeking large transformations, it focuses on constant, continuous steps forward.

Employee involvement is integral to Kaizen. Recognising their expertise and insights, Kaizen encourages active engagement from employees in identifying and contributing to improvement opportunities. This involvement fosters a culture of ownership, collaboration, and ongoing learning. By embracing Kaizen's meaning and principles, organisations can cultivate a culture of continuous improvement, tapping into their workforce's collective intelligence and dedication.

Key elements of Kaizen Methodology

Kaizen Methodology has gained recognition as a powerful approach for continuous improvement. In this section, we explore the key elements that form the foundation of Kaizen. From the role of standardisation to the essential tools used and the importance of employee empowerment and involvement, these elements contribute to the success of Kaizen initiatives.

Standardisation

Standardisation plays a critical role in Kaizen, driving process improvement and efficiency. Organisations can eliminate variations that hinder productivity and quality by establishing standardised procedures and practices. Standardisation ensures consistent execution, simplifies training processes, and facilitates the identification of areas for improvement.

It also enables organisations to gather reliable data, compare performance, and pinpoint bottlenecks or inefficiencies. Organisations can implement targeted improvements with a data-driven approach, enhancing overall process effectiveness.

Implement the Kaizen 5S system to enhance organization, eliminate waste, and create a productive, efficient work environment!

Continuous improvement tools

Kaizen employs various tools that facilitate continuous improvement. One such tool is the Plan-Do-Check-Act (PDCA) cycle, which involves planning the improvement, implementing it, checking the results, and acting to make necessary adjustments. The 5 Whys technique is another valuable tool used in Kaizen, helping to identify the underlying causes of a problem by repeatedly asking "why" until the root cause is revealed.

The Gemba walks involve observing processes firsthand, gathering insights, and identifying improvement opportunities. These tools empower organisations to systematically analyse issues, make data-driven decisions, and implement effective solutions.

Employee empowerment and involvement

One of the fundamental aspects of Kaizen is the involvement of employees at all levels. Empowering employees and involving them in the Kaizen process fosters a sense of ownership, innovation, and continuous improvement.

Actively engaging employees allows organisations to tap into their expertise, experience, and creativity. Employees become motivated to identify and address problems, suggest improvements, and implement changes. This involvement nurtures a culture of innovation, encouraging employees to think critically, propose new ideas, and experiment with process enhancements. It also develops a proactive mindset, where opportunities for improvement are continually sought, and positive change is driven throughout the organisation.

Try our Certified Kaizen Foundation & Practitioner Course today to reach unseen efficiency!

Implementing Kaizen in practice

To implement rapid and continuous improvement processes, it is crucial for organisations to cultivate a culture where employees are empowered to identify and resolve problems. Most organisations that implement Kaizen-type improvement processes have established methods and ground rules that are effectively communicated throughout the organisation and reinforced through training. Below are the basic steps for implementing a Kaizen "event," but organisations typically customise and sequence these activities to work efficiently within their unique circumstances.

Creating a Kaizen culture

Organisations must create a culture that embraces continuous improvement to implement Kaizen effectively. Several crucial steps facilitate the establishment of a Kaizen culture.

a) Leadership commitment: Demonstrating leadership commitment to Kaizen through active participation in improvement initiatives and emphasising its importance to all employees sets the tone for a culture of continuous improvement.

b) Fostering open communication: Cultivating an environment where employees feel safe to share ideas, concerns, and suggestions is vital. Regular communication sessions encourage employee engagement and involvement.

c) Training and education: Providing comprehensive training on Kaisen principles and tools equips employees with the knowledge and skills to identify improvement opportunities and effectively implement changes.

d) Recognition and celebration: Acknowledging and celebrating achievements reinforces the value of continuous improvement, fostering a culture that encourages ongoing engagement.

Discover essential Kaizen Tools to drive continuous improvement, streamline processes, and achieve operational excellence. Start optimizing today!

Kaizen events and projects

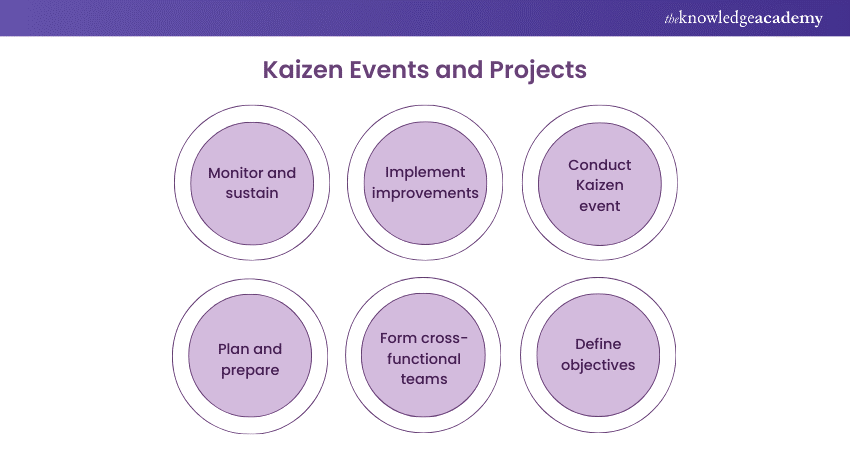

Implementing Kaizen events and projects can yield significant improvements within a focused timeframe. The following steps guide the successful execution of events and projects.

a) Define objectives: Clearly defining goals and objectives for the Kaizen event or project, including the specific problem or process to be addressed, helps focus efforts and establish desired outcomes.

b) Form cross-functional teams: Assembling teams comprising representatives from different departments promotes collaboration, diverse perspectives, and a holistic approach to problem-solving.

c) Plan and prepare: Developing a detailed plan outlining steps, timeline, and necessary resources ensures a structured approach. The availability of materials, data, and tools facilitates the improvement process.

d) Conduct Kaizen event: Utilising various improvement tools and techniques, such as process mapping and value stream analysis, during the event encourages active participation, engagement, and idea generation from team members.

e) Implement improvements: Based on the outcomes of the Kaizen event, identified improvements and changes can be implemented, with proper documentation ensuring consistency and future evaluations.

f) Monitor and sustain: Ongoing monitoring of implemented improvements, along with mechanisms for evaluation and feedback, helps sustain progress. Encouraging employee involvement in addressing emerging challenges further strengthens the culture of continuous improvement.

Discover the potential of continuous improvement with our Certified Kaizen Foundation Course!

Why implement the Kaizen Method?

Small incremental improvements can deliver significant results, creating a grassroots movement for Business Process Improvement(BPI). Kaizen promotes employee engagement by fulfilling three essential needs.

a) Connection: Feeling connected to a larger organisational purpose, their work, and co-workers.

b) Creation: There are opportunities to think creatively and come up with practical solutions for existing problems.

c) Control: Throughout the process, there should be a feeling of ownership and awareness.

Implementing the Kaizen Methodology can be an effortless manner to involve your employees and foster a culture of constant improvement. It might seem like a given, but employee engagement plays a vital role in the success of Business Processes. When you provide a framework that allows all employees to participate in the grand scheme of things by making small changes to their local environments, they are more likely to remain with the organisation, and their productivity will improve.

Unlock the power of Kaizen tools to enhance efficiency, drive continuous improvement, and achieve remarkable results in your organization. Learn more now!

Conclusion

In conclusion, Kaizen Methodology serves as a powerful approach to continuous improvement. Organisations can foster a culture of continuous improvement by creating a positive work culture, implementing events and projects, and measuring and sustaining the impact. This will help them drive significant enhancements and achieve long-term success. Embracing Kaizen as a practice enables organisations to innovate and thrive in an ever-evolving business landscape continuously.

Unleash the potential for continuous improvement with our Certified Kaizen Practitioner Course!

Frequently Asked Questions

Kaizen is a Japanese management philosophy that emphasises continuous improvement in all aspects of an organisation. The word "Kaizen" translates to "change for better." The theory encourages small, incremental changes and involves every level of the organisation, fostering a culture of continuous learning and improvement. Kaizen aims to enhance efficiency, productivity, and quality over time through the collective efforts of all employees.

Kaizen's core elements include teamwork for collective improvement, personal discipline in incremental changes, a positive environment that boosts morale, and the formation of quality circles to address specific challenges collaboratively. Employee involvement is crucial, with a focus on actively seeking and implementing suggestions for continuous enhancement in processes and systems.

The principles of Kaizen, a Japanese philosophy of continuous improvement, revolve around five key tenets. First, the identification and elimination of waste are paramount, targeting inefficiencies in processes to enhance overall productivity. Second, Kaizen advocates for incremental changes rather than large-scale transformations, promoting sustained and manageable improvements over time.

Third, the standardisation of processes is crucial for consistency and efficiency, providing a foundation for continuous enhancement. Additionally, the philosophy emphasises the importance of embracing a collaborative approach, involving all levels of the organisation in the improvement process. Finally, a commitment to continuous reflection and improvement ensures that the cycle of Kaizen persists, creating a culture of perpetual betterment within the organization.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Kaizen Courses, including Certified Kaizen Foundation & Practitioner, Six Sigma Green Belt, Certified Enterprise Architect Professional (CEAP) and many more. These courses cater to different skill levels, providing comprehensive insights into Kaizen Methodologies.

Our Business Improvement blogs cover a range of topics related to Kaizen, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your continuous improvement skills, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Business Improvement Resources Batches & Dates

Date

Certified Kaizen Foundation & Practitioner

Certified Kaizen Foundation & Practitioner

Wed 8th Jan 2025

Wed 2nd Apr 2025

Wed 6th Aug 2025

Wed 5th Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please