We may not have the course you’re looking for. If you enquire or give us a call on +65 6929 8747 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

The modern-day organisations are constantly seeking ways to optimise their processes, reduce waste, and enhance efficiency. Lean Six Sigma, a powerful methodology, offers comprehensive Lean Six Sigma toolkit for achieving these goals. In this blog, we will explore the Lean Six Sigma Tools that make it a driving force behind process improvement and organisational success.

Table of Contents

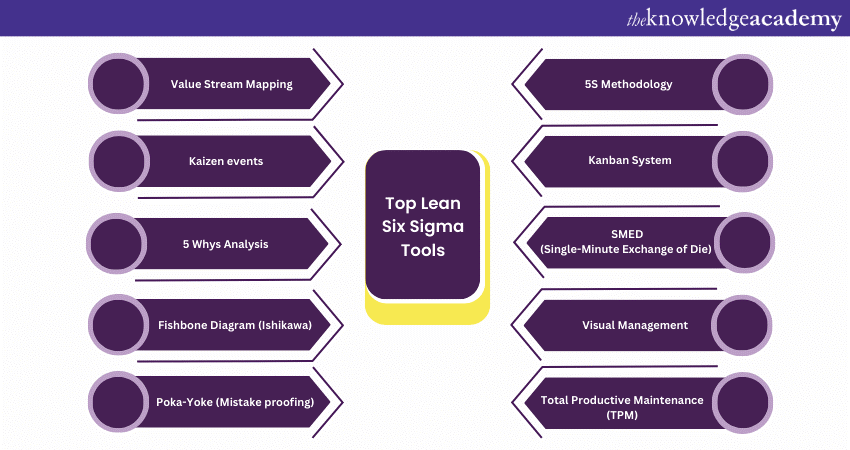

1) Top Lean Six Sigma Tools

a) Value Stream Mapping

b) Kaizen Events

c) 5 Whys Analysis

d) Fishbone Diagram (Ishikawa)

e) Poka-Yoke (Mistake proofing)

f) 5S Methodology

g) Kanban System

h) SMED (Single-Minute Exchange of Die)

i) Visual Management

j) Total Productive Maintenance (TPM)

2) Conclusion

Top Lean Six Sigma Tools

This section of the blog will expand on some of the most popular Lean Six Sigma Tools and techniques:

Value Stream Mapping

Value Stream Mapping (VSM) is a visual representation tool that captures and analyses the end-to-end process flow of a product or service. It aims to identify value-added and non-value-added activities, enabling organisations to streamline processes and eliminate waste.

VSM provides a clear visualisation of the current state, helping teams pinpoint bottlenecks and inefficiencies. By analysing the ideal future state, VSM guides process improvement initiatives by highlighting areas for enhancement. Overall, this tool facilitates cross-functional collaboration, aligns activities with customer needs, and promotes data-driven decision-making for sustained operational excellence.

Kaizen Events

Kaizen Events are intensive, focused improvement workshops designed to achieve rapid, tangible results. These events gather a diverse group of employees to brainstorm, analyse, and implement solutions to specific problems.

Kaizen Events foster a culture of continuous improvement and collaboration, resulting in quick wins that can drive positive change throughout the organisation. This tool's short duration and immediate impact make it an effective means of fostering employee engagement. As a result, it enhances processes and cultivates a mindset of constant enhancement.

5 Whys Analysis

One of the most popular Lean Six Sigma Tools is the 5 Whys Analysis. It is a problem-solving technique that delves deep into the root causes of an issue. By repeatedly asking "why" at least five times, teams can uncover underlying factors rather than merely addressing symptoms. This tool encourages critical thinking and thorough investigation, leading to more effective problem resolution.

Further, the 5 Whys Analysis enables organisations to identify hidden causes of inefficiencies and implement targeted solutions. By eliminating the source of problems rather than addressing their surface-level effects, this tool supports sustainable process improvement and fosters a culture of continuous learning.

Elevate your skills in Lean Six Sigma with our Lean Six Sigma Certification Training – join today for enhanced process excellence!

Fishbone Diagram (Ishikawa)

The Fishbone Diagram, also known as the Ishikawa or Cause-and-Effect Diagram, provides a structured framework for identifying potential causes of a problem. It visually categorises factors that contribute to an issue into various dimensions, such as people, process, equipment, materials, and environment.

By organising information in this manner, teams can systematically analyse and understand the complex relationships between causes and effects. Thus, the Fishbone Diagram encourages comprehensive brainstorming and cross-functional collaboration. This, in turn, leads to a deeper understanding of problems and more targeted improvement strategies.

Poka-Yoke (Mistake proofing)

Poka-Yoke, meaning "mistake-proofing" in Japanese, is a preventive approach to quality control. This tool focuses on designing processes and systems to prevent errors from occurring in the first place. By incorporating mechanisms such as physical barriers, sensors, and visual cues, organisations can reduce the likelihood of mistakes and defects.

Poka-Yoke enhances efficiency by reducing the need for rework, improving product quality, and boosting customer satisfaction. This tool reinforces a proactive mindset. It helps shift the focus from detecting and correcting errors to preventing them altogether.

5S Methodology

The 5S Methodology offers a systematic approach to workplace organisation, promoting cleanliness, efficiency, and productivity. The five steps are as follows:

a) Sort

b) Set in order

c) Shine

d) Standardise

e) Sustain

These steps guide employees in organising their workspaces optimally. By eliminating clutter, arranging tools logically, maintaining cleanliness, standardising processes, and sustaining improvements, organisations create an environment conducive to efficiency and continuous improvement. Moreover, the 5S Methodology enhances employee morale, reduces waste, and supports visual management practices. This ultimately contributes to streamlined processes and improved overall performance.

Kanban System

Originating from Toyota's production system, the Kanban System is a visual scheduling tool that facilitates the efficient management of workflow. It employs visual signals, typically represented by cards, to signal the need for replenishing inventory or starting a new task.

By limiting work in progress, the Kanban System prevents overproduction, minimises lead times, and optimises resource allocation. This tool fosters a just-in-time production approach, promoting flexibility and responsiveness to customer demand.

SMED (Single-Minute Exchange of Die)

Single-Minute Exchange of Die or SMED focuses on reducing the time an organisation takes to change equipment setups. It is a crucial aspect in industries with frequent product or process changes. By analysing and streamlining changeover procedures, organisations can minimise downtime, increase equipment availability, and enhance operational flexibility. SMED techniques include the following

a) Converting internal activities to external

b) Standardising setup tasks

c) Performing setup activities in parallel

This tool enables organisations to achieve quicker changeovers, respond to changing customer needs, and maximise equipment utilisation. This ultimately leads to improved overall efficiency.

Unlock the path to process excellence with our Lean Six Sigma Yellow Belt Training – join now!

Visual Management

Visual Management involves using visual cues, displays, and indicators to communicate information effectively. By using visual aids like charts, graphs, and colour-coded labels, organisations provide employees with quick access to important data and insights. Visual Management promotes transparency, allowing teams to monitor progress, identify issues, and make informed decisions at a glance.

Moreover, this tool enhances communication, encourages accountability, and supports a culture of continuous improvement. By visualising Key Performance Indicators (KPIs) and relevant information, organisations empower their workforce to drive operational excellence. They can also make timely adjustments to processes and strategies.

Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) is a proactive approach to equipment maintenance that aims to prevent breakdowns and defects. This tool involves operators in routine maintenance activities and emphasises continuous care for equipment. By conducting regular inspections, addressing small issues promptly, and implementing preventive measures, organisations can minimise downtime. They can also extend equipment lifespan and improve overall process reliability.

Thus, TPM fosters a sense of ownership among employees, instilling pride in maintaining equipment and contributing to a culture of excellence. By integrating preventive maintenance practices into daily operations, TPM supports uninterrupted production, enhances product quality, and boosts overall operational efficiency.

Conclusion

Incorporating an array of Lean Six Sigma Tools empowers organisations to navigate the complexities of process improvement. From Value Stream Mapping to Total Productive Maintenance, these tools offer a comprehensive toolkit for streamlining processes, reducing waste, enhancing quality, and fostering a culture of continuous improvement.

Unlock the power of Lean Six Sigma with our comprehensive Lean Six Sigma Black Belt Training – register now for enhanced results!

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please