We may not have the course you’re looking for. If you enquire or give us a call on 44 1344 203 999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

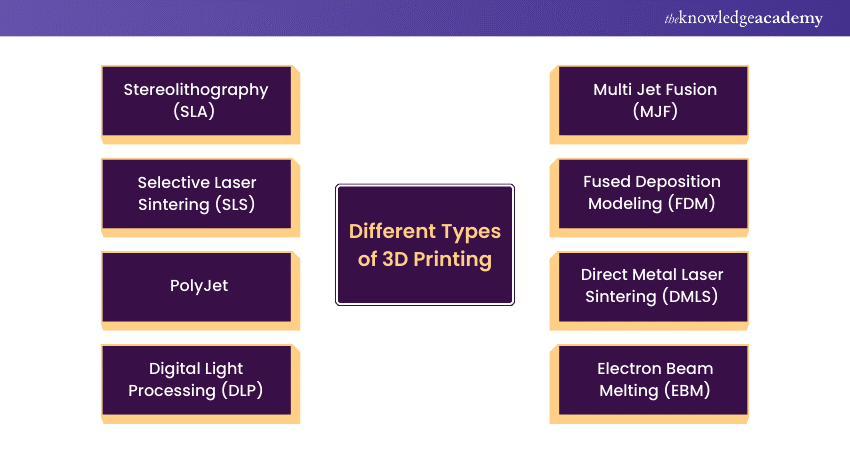

Welcome to our blog on the various Types of 3D Printing, an exciting realm of technology transforming the landscape of design and manufacturing. In this comprehensive blog, we will explore different Types of 3D Printing, including stereolithography (SLA), selective laser sintering (SLS), polyjet, digital light processing (DLP), and more. Let’s dive in.

Table of content

1) What is 3D Printing?

2) Different Types of 3D Printing

a) Stereolithography (SLA)

b) Selective Laser Sintering (SLS)

c) PolyJet

d) Digital Light Processing (DLP)

e) Multi Jet Fusion (MJF)

f) Fused Deposition Modeling (FDM)

g) Direct Metal Laser Sintering (DMLS)

h) Electron Beam Melting (EBM)

3) Conclusion

What is 3D Printing?

3D printing, often referred to as additive manufacturing, represents a transformative technological advancement. It fabricates three-dimensional items by sequentially adding material, layer upon layer, based on a digital blueprint. Unlike traditional subtractive manufacturing methods, which involve cutting or moulding material to create an object, 3D printing builds objects by adding material, allowing for intricate and complex designs that were previously challenging or impossible.

The origins of 3D printing trace back to the 1980s, marked by the invention of stereolithography (SLA) by Chuck Hull, which laid the foundation for the first 3D printing technology. Since then, various 3D printing methods have been developed, each offering unique advantages and applications.

Different Types of 3D Printing

Let's delve into the explanations for each of the Types of 3D Printing:

Stereolithography (SLA)

Stereolithography (SLA) is an additive manufacturing process that works by using a UV laser to solidify layers of liquid photopolymer resin. The 3D printer's build platform is submerged in a vat of liquid resin, and the UV laser traces the cross-section of the object layer by layer. After the completion of a layer, the build platform descends, allowing a fresh layer of liquid resin to be applied over the preceding one. This cycle continues, layer by layer, until the entire object is fully constructed. SLA is known for its high precision and ability to create intricate details, making it suitable for applications such as rapid prototyping and producing detailed models.

Explore our specialised 3D Printing Training and unlock the skills to master this transformative technology!

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) involves the use of a laser to selectively fuse powdered material, typically nylon or other thermoplastics, into a solid three-dimensional structure. The 3D printer spreads a thin layer of powdered material across the build platform, and the laser sinters the powder according to the cross-section of the object. This process is repeated layer by layer. One significant advantage of SLS is its ability to produce objects with complex geometries and without the need for support structures, as the unsintered powder acts as a natural support.

PolyJet

PolyJet technology operates by employing a print head that jets successive layers of liquid photopolymer onto a build tray. Each layer is instantly solidified and hardened upon exposure to UV light, immediately after it is deposited. PolyJet allows for the simultaneous deposition of multiple materials with different properties, enabling the creation of objects with varying colours, flexibility, and transparency within the same print. This makes it suitable for applications where detailed and multi-material prototypes are needed.

Ready to bring your drawings to life? Elevate your skills with our comprehensive 2D Animation Training.

Digital Light Processing (DLP)

DLP is similar to SLA but uses a digital light projector to cure entire layers of liquid resin simultaneously. The projector displays the entire layer's image at once, speeding up the printing process compared to traditional SLA. However, this method may sacrifice some surface quality compared to SLA.

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) is a powder-based 3D printing technology. The printer spreads a layer of powdered material (usually nylon) and selectively applies fusing and detailing agents using an array of inkjet print heads. The powder is then fused with infrared light, and the process is repeated layer by layer. MJF is known for its high printing speed, fine detail resolution, and the ability to produce functional prototypes with isotropic mechanical properties.

Fused Deposition Modelling (FDM)

FDM is one of the most common and widely used 3D printing methods. It works by extruding thermoplastic filament through a heated nozzle. In this process, material is methodically deposited in layers, with each new layer bonding and fusing to the previous one as it cools and solidifies. FDM is known for its affordability, simplicity, and suitability for creating large and durable prototypes. However, it may have limitations in terms of surface finish and precision compared to some other methods.

Ignite your passion for animation with our exclusive Animation Masterclass.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is a form of metal 3D printing where a high-powered laser is used to selectively melt and fuse particles of metal powder, including materials like aluminium, titanium, or stainless steel, building the object layer by layer. DMLS is capable of producing complex metal parts with high strength and precision. It is often used in aerospace, automotive, and medical industries where durable and intricate metal components are required.

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is another metal 3D printing method that uses an electron beam to melt and fuse metal powder. This process occurs in a high-vacuum environment, allowing for precise control over the melting and solidification of the metal powder. EBM is renowned for creating components with superior mechanical properties. It is frequently employed in scenarios requiring high-strength metal parts with intricate shapes, particularly in sectors like aerospace and healthcare.

Dive into the world of vibrant artistry with our Digital Painting Masterclass. Unleash your creativity, refine your technique, and elevate your digital painting skills!

Conclusion

In conclusion, 3D Printing, or additive manufacturing, has evolved into a diverse set of technologies that revolutionise how objects are designed and produced. Each Type of 3D Printing brings its own set of advantages and capabilities, catering to a broad range of applications across industries.

Unleash your creativity with our Animation and Design Training. Elevate your skills, craft compelling visuals, and embark on a journey of artistic expression.

Frequently Asked Questions

Upcoming Office Applications Resources Batches & Dates

Date

Animation Course

Animation Course

Fri 17th Jan 2025

Fri 7th Mar 2025

Fri 23rd May 2025

Fri 18th Jul 2025

Fri 12th Sep 2025

Fri 14th Nov 2025

Fri 12th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please