We may not have the course you’re looking for. If you enquire or give us a call on 44 1344 203 999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Are you curious about the intricate web connecting the products you use daily to their origins? That’s the magic of Supply Chain Management (SCM). Organisations can efficiently manage the flow of goods and services from start to end. But first, businesses need to understand What is Supply Chain Management to bring growth to their business.

The SCM discipline involves supervising goods, information, and finances at the various stages of a process, starting from the supplier, then manufacturer, wholesaler, retailer, and finally, the consumer. SCM consists of coordinating and integrating the flows across companies. Read this blog to gain an in-depth understanding of Supply Chain Management. Also, explore its importance, key components, and challenges.

Table of Contents

1) Understanding What is Supply Chain Management

2) Key objectives of Supply Chain Management

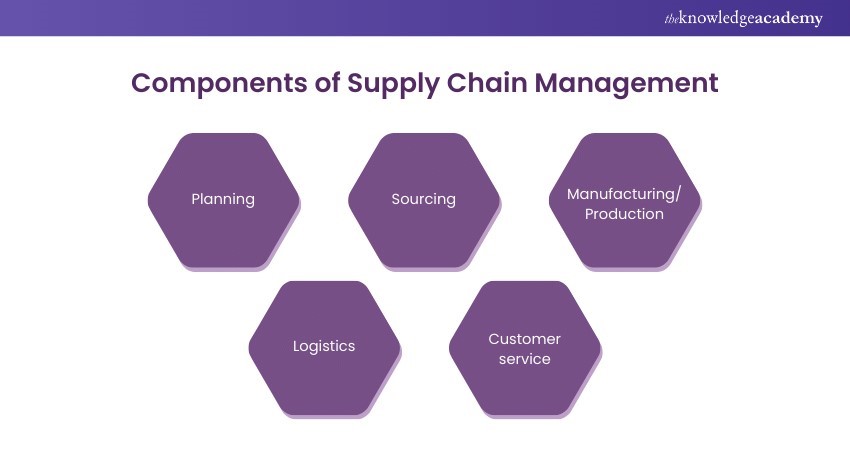

3) Components of Supply Chain Management

4) Importance of Supply Chain Management

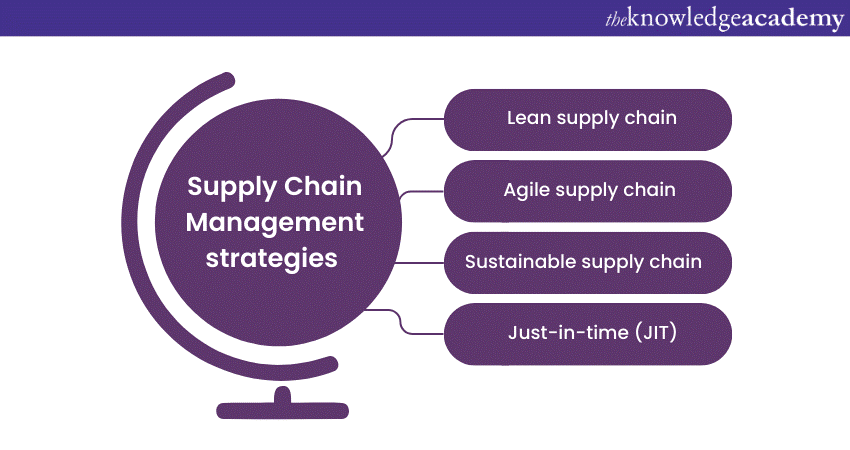

5) Supply Chain Management strategies

6) Challenges in Supply Chain Management

7) Conclusion

Understanding What is Supply Chain Management

Supply Chain Management is a strategic process of coordinating the movement of products, services, information and finances from the original material suppliers to the final customers. It ties different sections within the business together, reinforcing the product flow from start to finish.

Key objectives of Supply Chain Management

Let’s have a brief look at the main objectives of SCM and the impact it has on business operations:

Cost optimisation

One of the primary objectives of SCM is to optimise costs at every stage of the Supply Chain. Businesses can achieve cost efficiencies by monitoring processes, reducing wastage, and improving resource allocation. This leads to better profitability.

Efficient resource utilisation

The primary function of SCM is to properly use resources like raw materials, workforce, and production capacity. Through proper resource allocation, businesses reduce excessive inventory costs and enhance overall productivity.

Meeting customer demands

Consumers' expectations change each day, and SCM strives to provide solutions that help satisfy them appropriately. By producing and distributing products in line with customer needs, businesses can elevate customer satisfaction and retention.

Components of Supply Chain Management

After understanding What is Supply Chain Management, it’s time to learn its key components. SCM comprises several interconnected components that ensure the smooth flow of services and products from suppliers to customers. Various elements are listed below:

Planning

Planning is the fundamental element of SCM, comprising various activities that lay the groundwork for effective Supply Chain operations. Planning involves the following to make strategic decisions to improve the business:

a) Forecasting

b) Demand planning

c) Inventory management

Sourcing

Sourcing includes identifying and selecting suppliers who provide the necessary raw materials, components, or finished products. It also involves the following:

a) Identifying suppliers

b) Negotiating with them

c ) Management of supplier relationships

Manufacturing/Production

The manufacturing or production component transforms raw materials into finished products. It is effectively carried out through operations management and process optimisation.

Logistics

Logistics plays a crucial role in physically moving

a) Goods from suppliers to manufacturers

b) From manufacturers to distributors or retailers.

This includes transportation, warehousing and distribution.

Customer service

Customer service is a crucial aspect of SCM, focusing on delivering a positive experience to customers throughout the purchasing journey. The processes involved are as follows:

a) Processing of order

b) Delivery of the order

c) Post-sales support

These processes are carried out to maximise customer satisfaction.

Importance of Supply Chain Management

SCM benefits businesses when appropriately executed, allowing them to grow in the dynamic marketplace. So, it's crucial to understand its importance. Here’s the significance of SCM:

Cost reduction and increased efficiency

Proper SCM allows one to uncover areas of inefficiency and waste along an organisation's Supply Chain. Companies can cut operating costs and maximise efficiency through inventory optimisation and more effective resource allocation. Proper Supply Chain management saves time, minimises operating expenses, and increases cost savings at every point along the chain.

Enhanced customer satisfaction

Customer satisfaction is vital in maintaining a customer base and gaining a competitive advantage. SCM plays an essential role in delivering a fruitful customer experience. It facilitates effective communication and collaboration among Supply Chain partners, enabling quick responses to changing customer needs and preferences.

Improved inventory management

Strategic inventory management is a crucial balance and could be a significant financial determinant for the company. The fundamental strength of the SCM system is its capability to give quick access to information on inventories and general demand tendencies. This means that companies can have minimal stock holdings, the risk of stockouts will be eliminated or reduced, and businesses with high inventory carrying costs can be avoided.

Better risk management and Supply Chain resilience

Effective SCM allows businesses to build resilience and implement risk management strategies. Companies can reduce potential turmoil by diversifying suppliers, creating emergency plans, and establishing alternative distribution channels. They can also maintain continuity even in challenging circumstances.

Enhance your skills in Logistics Management through our Logistics Management Training - Reserve your seat now!

Supply Chain Management strategies

SCM strategies are designed to optimise processes, improve efficiency, and align with specific organisational goals. Here are a few strategies of SCM:

Lean Supply Chain

The Lean Supply Chain strategy emphasises the out-of-pocket costs and processes involved in Supply Chain Management. It is equally motivated by lean manufacturing and intended to decrease both production and lead time.

Businesses could adopt Lean methods in selecting areas with non-value-adding activities like surplus inventory, overproduction, and excessive transportation. This method enables constant improvement, and staff members can recognise the possibilities of process awareness.

Agile Supply Chain

The main characteristic of the Agile Supply Chain is its ability to handle market volatility and customer preferences. In uncertain and fluid conditions, businesses must be up to the challenges and ready for fast adjustments in the Supply Chain.

With Agile Supply Chain, real-time data analysis and close cooperation with Supply Chain partners are key factors that make this happen. This allows them to deal with the world's trends in demand and unexpected natural calamities.

Sustainable Supply Chain

The ecological and ethical Supply Chain strategy integrates environmental and ethical concerns into practices. By using sustainable techniques, costs can be reduced by optimising resources and making them energy-efficient.

Sustainable Supply Chain Management is rapidly growing in the contemporary world. Such organisations perpetually face the organisations of attending to environmental problems and being socially responsible.

Just-In-time (JIT)

Just in Time seems to keep the minimum amount of inventory needed for production or service delivery. This approach contributes to decreasing inventory holding costs and the risk of an inventory surplus.

JIT relies on coordination with suppliers and ensures timely delivery to meet production targets. It requires strong communication with Supply Chain partners to prevent altercations and collaborate well.

Challenges in Supply Chain Management

Although the latest technologies and tactics can overcome several problems in the Supply Chain, they are still facing specific difficulties that can affect smooth operations. Discussed below are some common challenges faced by Supply Chains:

Although the latest technologies and tactics can overcome a number of problems in the Supply Chain, they are still facing certain difficulties that can affect smooth operations. Discussed below are some common challenges faced by Supply Chains:

Demand variability and forecasting inaccuracies

Predicting customer demand ideally will always be strenuous for Supply Chain managers. The changing consumer behaviour, marketplace trends and external factors mainly fuel demand variability. As a result, forecast errors can result in unnecessary inventory costs or missed sales.

For this reason, companies should keep developing their forecast models. It should be done in close collaboration with sales and marketing teams on customer demand patterns.

Supply Chain disruptions

Supply Chain breakdowns stem from natural disasters, geopolitical turmoil, or unexpected events that may have an extensive impact on business operations. Such fluctuations may provoke the postponement of the production, transportation, and delivery processes.

Companies should have contingency plans in place to minimise risks. Risk management strategies, such as diversifying suppliers' bases and budgeting for interruptions, will help tackle the issues effectively.

Global Supply Chain complexities

With such a globalised Supply Chain, complex globalised international trade, custom regulations, and cross-border logistics become very important to deal with. Languages, currencies, and legal systems are just a few of the many communication barriers that lead to delays in the decision-making process.

Additionally, geopolitical tensions and trade policy changes may impede the flow of goods forward and backwards in global Supply Chains. Thus, applying the latest technologies, forming strong partnerships with local stakeholders, and being attentive to the geopolitical environment are the keys to continuing control over complexities in the global Supply Chain.

Unlock your facilitation potential – Sign up for our Facilitation Skills Training now!

Cyber Security threats and data breaches

Supply Chains are data-intensive, so cyber threats and data breaches are common in such an environment. The impact of such a cyber-attack is that it cripples the organisation's operations, completely confidential information and results in a vast inflow of money.

Therefore, companies must reinforce their Cyber Security approach to fight technological threats. The program must include data encryption, regular vulnerability tests, and the provision of Cyber Security courses to staff members.

Conclusion

After reading this blog, you got an idea about What is Supply Chain Management. The primary importance of SCM lies in optimising operations and meeting customer demands. Businesses must invest in strategic SCM practices to gain a competitive edge. By using effective measures and tackling challenges, companies can achieve incredible success.

Enhance your knowledge on current industry trends with our Industry Training– join now!

Frequently Asked Questions

The 4 Cs of Supply Chain Management are

a) Capacity

b) Consistency

c) Collaboration

d) Cost

The benefits of SCM are:

a) Efficiency

b) Reduces costs

c) Improves product quality

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Industry Courses including Supply Chain Management Training, Facilities Management Training and Product Management Training. These courses cater to different skill levels, providing comprehensive insights into Facilitation methodologies.

Our Business Skills Blogs cover a range of topics related to Supply Chain Management offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your skills as a Supply Chain Manager, The Knowledge Academy's diverse courses and informative blogs have you covered.

Upcoming Business Skills Resources Batches & Dates

Date

Supply Chain Management Training

Supply Chain Management Training

Fri 3rd Jan 2025

Fri 28th Mar 2025

Fri 23rd May 2025

Fri 4th Jul 2025

Fri 5th Sep 2025

Fri 24th Oct 2025

Fri 5th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please