We may not have the course you’re looking for. If you enquire or give us a call on +27 800 780004 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Risk is inherent to any work environment, but we can ensure a safer, healthier, and more productive work atmosphere by managing these risks effectively. One globally recognised system for this is the IOSH Hierarchy of Risk Control (HRC). This comprehensive framework helps businesses identify, evaluate, and manage risks systematically.

According to a study by Health and Safety Executive, approximately 83 per cent of companies provide training to their employees for workplace safety duties.

This blog aims to provide you with an ultimate guide to understanding the IOSH Hierarchy of Risk Control.

Table of Contents

1) What is the IOSH Hierarchy of Risk Control?

2) Stages involved in IOSH HRC

3) Implementing the IOSH HRC

4) Importance of the IOSH HRC

5) Conclusion

What is the IOSH Hierarchy of Risk Control?

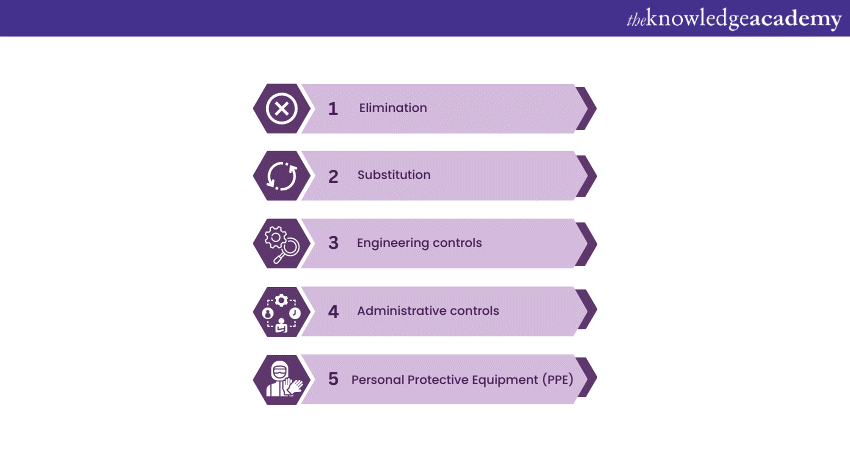

The IOSH Hierarchy of Risk Control (IOSH HRC) is a fundamental aspect of occupational safety and health. It provides a structured approach to reducing workplace hazards by implementing controls based on their effectiveness. This system prioritises the most effective control measures, eliminating hazards, over fewer effective measures, like Personal Protective Equipment (PPE).

The foundation of IOSH HRC is the complete removal or elimination of the hazard, with the last resort being the use of PPE. In essence, it provides organisations with a logical sequence of decision-making tools to reduce risks, aiming to foster a safer, healthier work environment and, ultimately, minimise the occurrence of workplace accidents and illnesses. By ingraining the HRC in their safety and health management systems, businesses can demonstrate a genuine commitment to their employees' well-being and uphold their legal obligations under health and safety legislation.

Stages involved in IOSH HRC

The Hierarchy of Risk Control consists of five key stages:

a) Elimination: This stage represents the most effective control measure. It involves identifying and removing the hazard entirely from the workplace, thus obliterating any risk associated with it. For example, if a particular process or task is found to be inherently dangerous, the best action is to cease this activity entirely.

b) Substitution: When elimination isn't viable, the next best alternative is substitution. This involves replacing the hazardous element with something less risky. For instance, if a hazardous chemical is used in a process, the substitution would involve identifying a less hazardous chemical that can perform the same function. It is essential to ensure that the substitute doesn't introduce new hazards.

c) Engineering controls: This level aims to manage the risk by incorporating physical changes to the workplace or the equipment. Such changes often involve redesigning machinery, isolating Employees from hazards, or implementing safety devices. For instance, installing physical guards on machinery to prevent access to moving parts or improving ventilation systems to mitigate exposure to harmful substances.

d) Administrative controls: When engineering controls aren't feasible or don't eliminate the hazard entirely, the next level of control is organisational measures. These involve changes in work procedures, such as reducing the duration or frequency of exposure to the hazard, providing adequate rest breaks, rotating workers, and implementing effective training and education programmes. The goal is to reduce the risk by altering how or when workers interact with the hazard.

e) Personal Protective Equipment (PPE): This is the least effective control in the hierarchy and should be utilised as a last resort when other controls aren't possible or can't fully protect workers. PPE doesn't reduce the hazard itself but provides a barrier between the worker and the threat. Examples include safety glasses, earplugs, gloves, safety boots, and respirators. It's important to note that PPE's correct use and maintenance are crucial to its effectiveness.

Implementing the IOSH HRC

Implementing the HRC requires a systematic approach. Here are seven steps:

a) Identify the hazards: The first step in the process is to recognise all potential hazards in the workplace. This requires a comprehensive understanding of the workplace and its operations. Tools such as safety audits, risk assessments, and inspections can help identify these hazards. In addition, input from employees who are directly involved in the tasks and processes can be invaluable, as they often have a keen awareness of the risks involved.

b) Assess the risks: After identifying potential hazards, it's essential to assess the level of risk associated with each one. This involves considering the likelihood of an incident occurring due to the hazard and the severity of the potential harm or injury. This evaluation should take into account existing control measures and their effectiveness. Often, a risk matrix is used to prioritise the risks, providing a clear picture of which hazards need urgent attention.

c) Control the risks: Once the risks have been identified and assessed, it's time to implement measures to control them. The Hierarchy of Risk Control provides the framework for deciding on the most effective control measures. Starting from the top, consider if the hazard can be eliminated. If not, can it be substituted, or can engineering controls be applied? If these are not possible, look at administrative controls and, finally, the use of PPE.

d) Review control measures: Implementing control measures is not a one-off task but an ongoing process. Regularly review and evaluate the control measures to ensure they remain effective. This should be done at regular intervals and when significant workplace changes, such as new equipment, processes, or personnel. If control measures are ineffective or new hazards are identified, go back to step one and repeat the process.

e) Involve stakeholders: A crucial aspect of implementing the Hierarchy of Risk Control is involving all Stakeholders in the process, particularly those directly affected - the employees. Workers often have unique insights into their work environment, and their input can be invaluable in identifying hazards and developing practical control measures. Encourage open and Effective Communication and ensure employees feel safe in reporting potential threats.

f) Documentation and communication: Documenting each step of the implementation process is vital for transparency and accountability. This includes the details of identified hazards, risk assessments, chosen control measures, and the reasoning behind those choices. Once control measures are in place, communicate them clearly to all employees to ensure they are understood and followed. Remember, the most effective safety measures are only useful if everyone is aware of them and knows how to apply them correctly.

g) Provide training and resources: Effective implementation of the Hierarchy of Risk Control requires adequate training and resources. Training should cover hazard identification, risk assessment, and the proper use of control measures, including the correct use and maintenance of personal protective equipment (PPE). Providing the necessary resources, whether it be safety equipment or time for safety meetings, shows a commitment to safety and can improve the overall effectiveness of the risk management strategy.

Importance of the IOSH HRC

The Hierarchy of Risk Control is crucial in maintaining a safe working environment. It helps reduce the likelihood of accidents and injuries and enhances productivity by creating a healthier, more efficient workplace.

Furthermore, implementing the HRC demonstrates a company's commitment to safety, which can boost morale, enhance reputation, and potentially reduce liability and insurance costs. Listed below are six reasons why organisations should implement the IOSH HRC:

a) Prevention of Accidents: The primary goal of the Hierarchy of Risk Control is to prevent workplace accidents. By following the hierarchy, businesses can systematically remove or reduce hazards, decreasing the likelihood of injuries or illnesses.

b) Compliance with Legislation: Using the Hierarchy of Risk Control helps companies comply with health and safety laws and regulations. It can guide businesses in demonstrating that they've taken every reasonable step to protect employees from harm, a legal obligation in many jurisdictions.

c) Worker Satisfaction: A safer work environment, facilitated by the effective implementation of the Hierarchy of Risk Control, can lead to improved worker satisfaction. Employees who feel their safety is a priority will likely be more content, loyal, and productive.

d) Economic Benefits: By preventing accidents and health issues, the Hierarchy of Risk Control can save companies considerable costs in lost time, worker compensation, insurance premiums, legal fees, and potential fines from non-compliance with safety regulations.

e) Enhanced Reputation: A strong commitment to safety, demonstrated by the use of proven systems such as the Hierarchy of Risk Control, can boost a company's reputation. Customers, suppliers, and potential employees are more likely to choose companies prioritising safety.

f) Continual Improvement: The Hierarchy of Risk Control provides a framework for continuous improvement in safety and health. By regularly reviewing and updating control measures, businesses can keep up with changes in technology, legislation, and working practices, ensuring that their Risk Management stays effective and relevant.

Conclusion

The IOSH Hierarchy of Risk Control is an invaluable framework all organisations should adopt to manage risks effectively. By implementing this hierarchy, companies can promote a safety and health culture, benefiting not only the workers but also the business as a whole. Remember, workplace safety is not just about compliance; it's about safeguarding the lifeblood of your organisation.

Learn how to create an effective health and safety framework for your workplace – Sign up for IOSH Managing Safely today!

Frequently Asked Questions

Upcoming Health & Safety Resources Batches & Dates

Date

IOSH Managing Safely Course

IOSH Managing Safely Course

Mon 10th Feb 2025

Mon 28th Apr 2025

Mon 16th Jun 2025

Mon 28th Jul 2025

Mon 1st Sep 2025

Mon 3rd Nov 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please