We may not have the course you’re looking for. If you enquire or give us a call on +27 800 780004 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

In the bustling marketplace of modern business, where every decision can either propel a company forward or hold it back, one strategy stands out: Sourcing. But What is Sourcing exactly? It’s not just about purchasing products or securing services; it’s the strategic art of building a robust supply chain that powers your business.

Imagine having the ideal suppliers delivering precisely what you need, exactly when you need it—cutting costs, enhancing quality, and driving innovation. Sourcing is the key to making that vision a reality. Whether your goal is to streamline operations, reduce expenses, or gain a competitive edge, understanding Wha is Sourcing can unlock a world of possibilities.

Table of Contents

1) Understanding What is Sourcing?

2) Different Types of Sourcing

3) The Sourcing Process

4) Benefits of Sourcing

5) Challenges in Sourcing

6) How to Improve Sourcing Strategies?

7) Conclusion

Understanding What is Sourcing?

Sourcing is the process of finding, evaluating, and engaging suppliers for different goods and services for the organisation. This involves the identification of reliable suppliers, negotiation of contracts, and ensuring that the buying of the products or services is of high quality at the best possible price.

Sourcing isn't just buying; it's relationship-building, cost-optimising, and maintaining a steady supply chain. This is a very important strategy that often leads to an organisation's success, and it will directly affect production efficiency, cost management, and product quality.

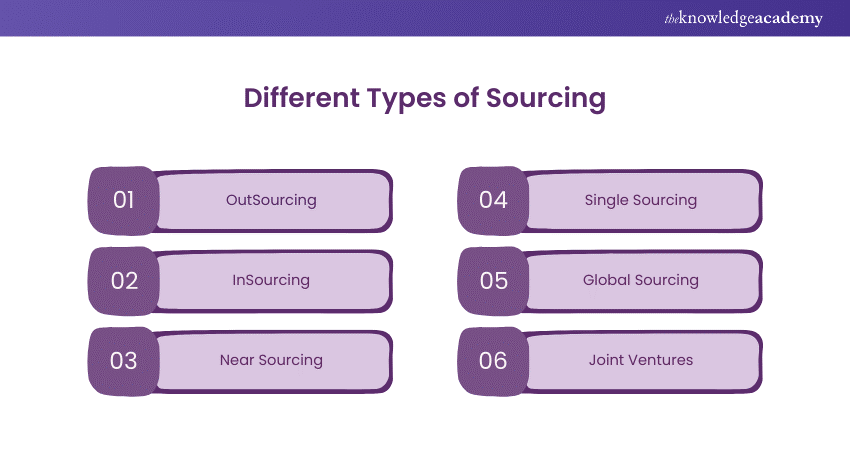

Different Types of Sourcing

There are many kinds of Sourcing activities, each of which fits a particular need and business goal. Some common types are listed below.

OutSourcing

OutSourcing involves contracting outside suppliers to undertake a certain business function or services, usually done in the firm. This enables a firm to focus on key competencies while taking advantage of specialised skills, resources, or lower costs of third-party providers. The most common areas for OutSourcing include IT services, customer support, and manufacturing.

InSourcing

Contrary to OutSourcing, which involves farming out processes or finding internal resources to perform work that has been outsourced, InSourcing brings the work inside. This approach allows organisations to have more control over the process and can result in better communication and a more integrated approach to doing business. Companies consider this strategy when quality control, protection of intellectual property, or rapid responsiveness is paramount.

Near Sourcing

Near Sourcing refers to "the process of relocating business processes or production to a location closer to the home market of a company, typically within neighbouring countries." This reduces shipping costs by streamlining supply chains through proximity and time zones. Therefore, Near Sourcing is particularly appealing to those companies that must balance the advantages of OutSourcing with quicker turnarounds and greater supervision.

Single Sourcing

Single Sourcing refers to the organisation of dependent relationships based on one source or one supplier of some specific product or service. This will provide one with strong partnerships and better negotiation powers but also tends to carry risks such as disruptions in supply chains or depending on one provider. Companies go for Single Sourcing in instances when a supplier is providing something quite unique or highly specialised.

Global Sourcing

Global Sourcing is defined as buying goods and services from international markets for better cost efficiencies, new technologies, or high-grade products. It thus allows firms to tap into a wider pool of suppliers around the world. It can yield substantial cost savings. However, it also means dealing with regulatory environments that vary across countries, cultural diversity, and increased logistical complexities.

Joint Ventures

A joint venture involves a collaboration in Sourcing wherein another company jointly supplies resources, expertise, or technology to create goods or services. This Sourcing option allows firms to leverage their combined strengths, share risks, and even enter new markets. Most Joint Ventures exist in industries that either require heavy investments or specialised knowledge, such as manufacturing automobiles or pharmaceuticals.

The Sourcing Process

Sourcing is comprised of several steps to ensure effective and efficient procurement of goods and services. Let us explain each stage in detail:

1) Needs Assessment

Sourcing initiation begins with the identification of needs related to the organisation's needs, thereby understanding the product or service required, specification, and desired outcomes. A well-conducted needs assessment helps define the scope of the Sourcing activities and lays the foundational structure for the selection of the right suppliers.

2) Identifying Suppliers

The second step, after the needs have been identified, is to select potential suppliers who could provide such needs. This covers market research on suppliers' capabilities, cost, quality, reliability, and reputation. It is important that a pool of potential suppliers be created to enable competitive bidding and negotiation.

3) Request for Proposal (RFP)

The request for proposal requires that the suppliers provide their proposals that include how they are going to meet organisational needs. An RFP should therefore contain scope of work, dates of completion, requirements of evaluation, and other special needs. This step is very crucial for the evaluation of supplier capabilities and determining competitive offers.

4) Evaluating Proposals

Following the receipts of the proposals, it would have to be evaluated, that is obtained, against set criteria such as cost, quality, experience, and delivery timelines. A scoring system may be used as part of the selection procedures, interviews, and visits to the facilities of the suppliers. This would point to the selection of the supplier best fitting the needs and goals of the organisation.

5) Negotiating Contracts

Once selected, attention turns to negotiating the contract terms: price, delivery schedule, payment terms, and other conditions. Successful negotiation here will ensure both parties understand what each can expect, with optimal terms for the organisation.

6) Contract Execution

The contract execution stage is where the finalisation and signing of the contract by the contracting party with the selected supplier take place. This is a written contract that legally sets terms, conditions of the relationship, and most definitely establishes the delivery of goods or services. Proper management of the contract should be undertaken to minimise the risks identified and ensure that the agreed terms are complied with.

7) Monitoring Performance

This is the final stage of the Sourcing process, where the performance of the supplier is monitored to ensure that their contractual agreement is met. In this regard, it involves tracking the KPIs, reviews, and resolving issues as they occur. Continuous monitoring of the performance maintains quality, optimises cost, and ensures good relations between the suppliers and buyers.

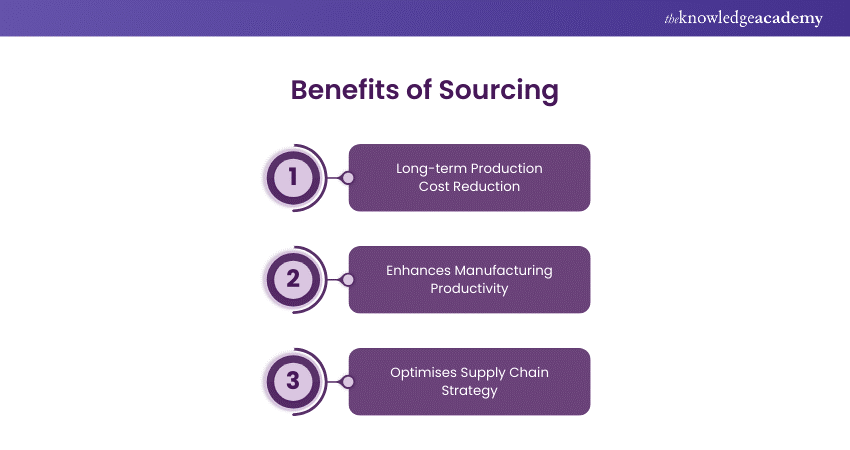

Benefits of Sourcing

Sourcing, if carried out efficiently, has several benefits that add value to the success of an organisation. This includes:

Long-Term Production Cost Reduction

The most significant benefit of Sourcing is the cost savings that are long-term. There is a lot to be said about production costs saved by companies because, through strategic Sourcing, these companies identify suppliers offering competitive pricing and adhere to the quality standards over time. This will make sure that a firm optimises its spending on the products and allocates the resources in the best possible manner.

Enhances Manufacturing Productivity

Sourcing proper materials and services plays a crucial role in holding the production processes together. Good suppliers will guarantee companies access to various vital components, besides assuring fewer production disruptions and delays. This enhances the overall productivity of manufacturing, thus granting companies a better avenue to meet customer demands more effectively.

Optimises Supply Chain Strategy

Sourcing effectively will optimise the chain so that every link in the chain will be strong and reliable. Effective souring creates a robust network of suppliers, reduces lead times, and improves overall flow throughout. The bottom-line impact of such a supply chain strategy will be operational efficiency and a stronger market position.

Unleash your product potential! Our Product Management Training will equip you with the skills to drive innovation. Start your journey today.

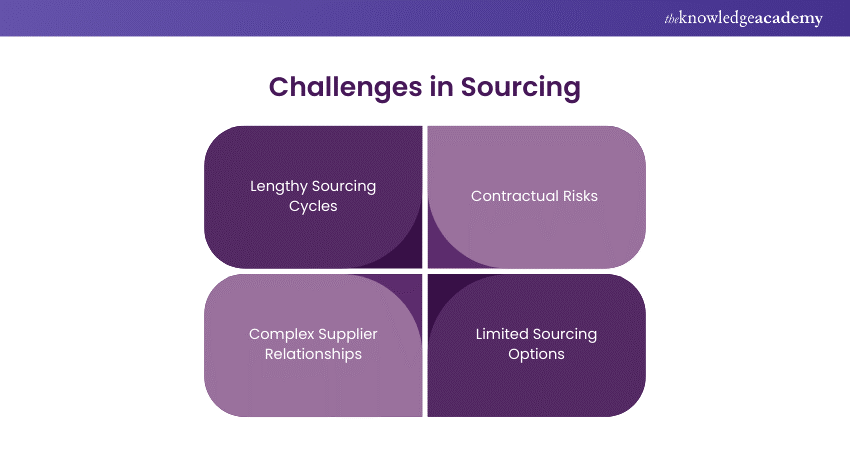

Challenges in Sourcing

While there are considerable benefits to Sourcing, it does present some challenges of its own for organisations to get around to achieve those benefits. These include:

Lengthy Sourcing Cycles

Sourcing can be a very time-consuming process, particularly if the deals are complex or the number of suppliers is large. Complex Sourcing cycles contribute to delays in production, increase costs, and put the organisation at a disadvantage in the market. The renovation of the process of Sourcing and the use of technology can reduce these complications to a minimum.

Contractual Risks

There is one kind of risk involved in entering contracts with suppliers, whether related to price, delay in delivery, or quality. In cases of bad deals, the outcome may be financial loss or disruption in supply. Therefore, robust practices in contract management are needed to minimise these risks.

Complex Supplier Relationships

This can be quite complicated, especially when the setting involves global or multi-tiered supply chains. The miscommunication, cultural differences, and differences in ways of doing business may cause several complications in managing suppliers. The ideal way of meeting these challenges is to establish strong and transparent relationships with the suppliers.

Limited Sourcing Options

Sometimes, organisations feel their Sourcing options are limited by market constraints, specialised requirements, or geopolitical factors. This could further create over-dependence on a few suppliers, hence increasing risk towards disruption in the supply chain. The diversification of the supplier base, considering alternative Sourcing strategies, may be helpful in such regards.

How to Improve Sourcing Strategies?

The improvement in Sourcing strategies involves several steps that may be characterised by proactive motives and continuous improvement. Briefly, the improved Sourcing strategy may be underlined as illustrated below.

Defining Sourcing Goals and Objectives

The first step to improving Sourcing strategies will be to clearly define your goals and objectives. Whether it is cost reduction, quality improvement, or supply chain resilience, having a clear vision helps guide Sourcing decisions and align them with the overall strategy of the organisation.

Conducting Needs Assessments

Needs assessments are done periodically, thereby aligning Sourcing activities with the dynamic needs of an organisation. This analysis helps analyse gaps, refine the specifications, and make necessary adjustments in the Sourcing strategy to meet business needs effectively.

Evaluating Potential Suppliers

Thorough evaluation is required to choose the right partners. This involves assessment of their financial stability, their performance in the past, and their capacity to meet your requirements. A well-conducted selection process minimises risks and brings success to a supplier relationship.

Selecting the Right Supplier

The selection of a supplier does not end with the price only. The quality standards, timely delivery, and the organisation's values that a supplier can assure are some key concerns that need to be focused on for selecting a supplier. A strategic selection enables the building of a strong and long-term partnership.

Monitoring Supplier Performance

Monitoring of the suppliers is done on a continual basis to control the quality and address issues arising. Regular reviews of performance, feedback mechanisms, and certain performance metrics have provided an assurance that suppliers would keep meeting expectations and continue with the success of the organisation.

Master the art of efficiency! Join our Supply Chain Management Training and Transform your Operations Today.

Conclusion

Sourcing is more than a business function—it's a strategic tool that drives organisational success. Understanding What is Sourcing and mastering its fundamentals can unlock efficiencies, reduce costs, and strengthen supply chains. By refining your Sourcing strategies and choosing the right partners, you position your business to adapt, thrive, and lead in a dynamic market. Invest in your Sourcing strategy today, as the right approach can make all the difference in achieving your goals.

Elevate your Career in Facilities Management! Unlock Expert Skills and Strategies with our Facilities Management Training —Start now

Frequently Asked Questions

Sourcing is used to identify and engage suppliers who provide goods or services at optimal quality and cost. It helps businesses reduce production costs, improve efficiency, maintain a steady supply chain, and foster reliable supplier relationships, enhancing overall competitiveness.

The role of Sourcing is to secure the best suppliers for a company’s needs, ensuring cost-effectiveness, quality, and reliability. It involves evaluating supplier options, negotiating contracts, and managing relationships to support the organisation’s strategic goals and operational requirements.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 19 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various Industry Trainings, including the Product Management Training, and the Facilities Management Training. These courses cater to different skill levels, providing comprehensive insights into Supply Chain Management Process.

Our Business Skills Blogs cover a range of topics related to Sourcing, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Sourcing Skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Upcoming Business Skills Resources Batches & Dates

Date

Product Management Training

Product Management Training

Fri 27th Dec 2024

Fri 21st Feb 2025

Fri 25th Apr 2025

Fri 20th Jun 2025

Fri 29th Aug 2025

Fri 31st Oct 2025

Fri 19th Dec 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please