We may not have the course you’re looking for. If you enquire or give us a call on +44 1344 203 999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

ISO 9001:2015 guides organisations toward establishing, implementing, and maintaining effective Quality Management Systems (QMS). At its core, this standard emphasises the importance of Monitoring and Measurement. The ISO 9001:2015 Monitoring and Measurement Procedure caters to the proper functioning of the aforementioned processes. These processes help organisations gauge performance against set objectives and customer expectations in Quality Management.

In this blog, we will unravel the intricacies of ISO 9001:2015 Monitoring and Measurement Procedure and shed light on its profound significance; read more to find out!

Table of Contents

1) Understanding ISO 9001:2015

2) What is ISO 9001:2015 Monitoring and Measurement Procedure?

3) Importance of ISO 9001:2015 Monitoring and Measurement Procedure

4) Key elements of ISO 9001:2015 Monitoring and Measurement Procedure

5) Conclusion

Understanding ISO 9001:2015

The International Organization for Standardization (ISO) introduced the ISO 9000 series in 1987, setting a benchmark for Quality Management practices. Over the years, this series has evolved, with ISO 9001:2015 being the latest and most comprehensive version.

1) Scope and Purpose

ISO 9001:2015 is an international standard that specifies the requirements for a Quality Management System (QMS). Organisations use it to demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements. It is applicable to any organisation, regardless of its size or industry.

2) Structure and Clauses

The ISO 9001:2015 standard follows the High-Level Structure (HLS) used in other ISO management standards, consisting of 10 main clauses:

1) Scope

2) Normative References

3) Terms and Definitions

4) Context of the Organisation

5) Leadership

6) Planning

7) Support

8) Operation

9) Performance Evaluation

10) Improvement

Each clause includes specific requirements that organisations must meet to comply with the standard.

3) Risk-Based Thinking

ISO 9001:2015 emphasises a risk-based approach to Quality Management. This involves identifying potential risks and opportunities that could impact the QMS and taking appropriate actions to address them. Risk-based thinking ensures that the organisation is proactive in managing potential issues and capitalising on opportunities for improvement.

4) Context of the Organisation

Organisations must understand their internal and external context, including relevant stakeholders and their needs and expectations. This involves analysing factors such as industry trends, market conditions, legal requirements, and internal capabilities. Understanding the organisation's context helps to establish a QMS that is aligned with its strategic direction.

5) Leadership and Commitment

Top management plays a crucial role in the implementation and maintenance of the QMS. They are responsible for establishing a quality policy, setting quality objectives, and ensuring that the QMS is integrated into the organisation’s processes. Leadership commitment is vital for driving a quality-focused culture and achieving continuous improvement.

6) Process Approach

ISO 9001:2015 encourages organisations to adopt a process approach to Quality Management. This involves understanding and managing the interrelated processes that make up the QMS. By focusing on processes, organisations can identify opportunities for improvement, reduce waste, and enhance efficiency and effectiveness.

7) Performance Evaluation

Organisations must monitor, measure, analyse, and evaluate the performance of their QMS. This includes conducting ISO 9001 Internal Audits, management reviews, and customer satisfaction surveys. Performance evaluation helps organisations to assess the effectiveness of their QMS and identify areas for improvement.

8) Continuous Improvement

Continuous improvement is a core principle of ISO 9001:2015. Organisations are required to identify and implement opportunities for improvement to enhance the quality of their products and services. This involves analysing non-conformities, implementing corrective actions, and fostering a culture of innovation and learning.

What is ISO 9001:2015 Monitoring and Measurement Procedure?

The ISO 9001:2015 Monitoring and Measurement Procedure is a systematic and structured approach organisations implement to ensure the effective monitoring and measurement of key processes, products, and services in compliance with the ISO 9001:2015 Quality Management requirements.

This procedure enables organisations to consistently evaluate their performance, assess their conformity to established Quality objectives and customer requirements, and gather valuable data to drive informed decision-making and continuous improvement.

It encompasses various elements, including defining clear objectives and Key Performance Indicators (KPIs), collecting and analysing relevant data, determining monitoring frequencies, and maintaining detailed records. Ultimately, the Monitoring and Measurement Procedure is a vital component of ISO 9001:2015 Clause 6.1, contributing to achieving Quality excellence and fulfilling customer expectations.

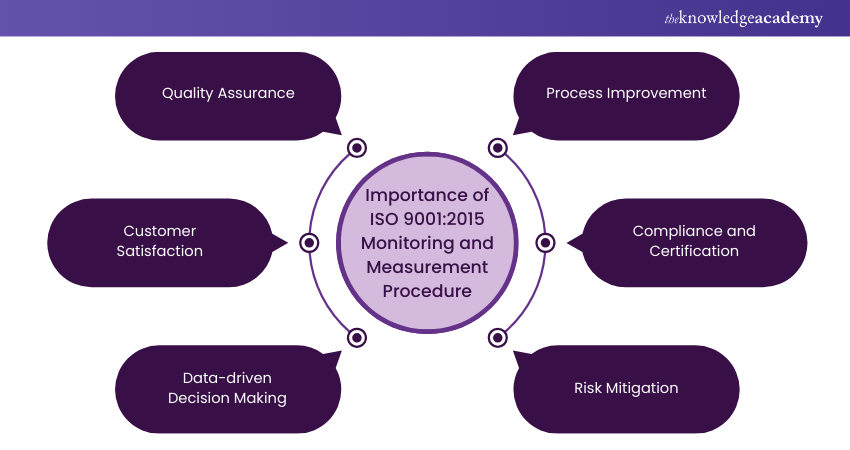

Importance of ISO 9001:2015 Monitoring and Measurement Procedure

Let us go over the importance of ISO 9001 2015 Monitoring and Measurement Procedure:

Quality Assurance

The ISO 9001:2015 Monitoring and Measurement Procedure is the linchpin of Quality assurance within an organisation. It is a robust Quality Control mechanism, ensuring that products, processes, and services consistently meet or exceed customer expectations. By closely monitoring and measuring Key Performance Indicators, an organisation can promptly identify deviations from desired standards and take corrective actions.

Customer Satisfaction

In the modern business landscape, customer satisfaction is paramount. ISO 9001:2015 focuses strongly on understanding and fulfilling customer requirements. The Monitoring and Measurement Procedure provides the means to assess how well an organisation meets these ISO 9001 Requirements. By collecting and analysing data related to customer feedback, complaints, and product/service performance, companies can make improved decisions to enhance customer satisfaction and loyalty.

Data-driven Decision Making

Informed decision-making is at the core of effective management. The Monitoring and Measurement Procedure supplies organisations with valuable data insights. These insights can range from production efficiency metrics to customer feedback trends. Such data empowers leaders to make informed decisions, allocate resources effectively, and set realistic goals for continual improvement.

Continuous Improvement

Among the fundamental principles of ISO 9001:2015 is continuous improvement. The Monitoring and Measurement Procedure is a catalyst for this process. By regularly monitoring and measuring processes, organisations can pinpoint inefficiencies, bottlenecks, and areas for enhancement. Continuous improvement becomes an ongoing cycle, increasing operational efficiency and cost-effectiveness.

Compliance and Certification

For many organisations, an ISO 9001:2015 Certification is a competitive advantage and a requirement in certain industries. The Monitoring and Measurement Procedure is instrumental in demonstrating compliance with ISO 9001:2015 standards during ISO 9001 Certification audits. This procedure showcases an organisation's commitment to Quality Management and its ability to maintain consistency in processes and outputs.

Risk Mitigation

Modern business environments are rife with uncertainties and risks. The Monitoring and Measurement Procedure incorporates risk-based thinking, enabling organisations to proactively identify and mitigate potential risks to product quality, customer satisfaction, and overall business success. This proactive approach helps organisations stay resilient in the face of challenges.

Learn how to implement Quality Management to achieve organisational goals, sign up for our ISO 9001 Lead Implementer now!

Key elements of ISO 9001:2015 Monitoring and Measurement Procedure

The successful implementation of the ISO 9001:2015 Monitoring and Measurement Procedure relies on several crucial elements that ensure its effectiveness and alignment with the overarching Quality Management goals of an organisation:

Define Objectives and Metrics

This procedure's core is establishing clear objectives and Key Performance Indicators (KPIs). Organisations must define what they intend to monitor and measure. They must also set Specific, Measurable, Achievable, Relevant, and Time-bound (SMART) objectives. These objectives and metrics should align with the organisation's Quality policy and strategic goals, providing a focused framework for assessment.

Monitoring Frequency

Determining how often Monitoring and Measurement activities should occur is critical. Some processes may necessitate daily monitoring to maintain Quality Control, while others may be assessed monthly or quarterly. The frequency of monitoring should be tailored to the specific nature of the process, its criticality, and the organisation's objectives.

Documentation and Record Keeping

Accurate documentation and record-keeping are essential components of ISO 9001:2015 compliance. The procedure mandates that all data collected during Monitoring and Measurement activities be meticulously recorded and maintained for future reference and auditing purposes. Proper ISO 9001 Documentation ensures transparency, traceability, and the ability to demonstrate compliance during external audits.

Corrective and Preventive Actions

Incorporating a mechanism for corrective and preventive actions is integral to this procedure. When monitoring reveals deviations from established standards or objectives, organisations must have a process to initiate corrective actions to address immediate issues and preventive actions to prevent recurrence. This proactive approach ensures continuous improvement and the prevention of Quality-related problems.

Gain skills to manage a team of Auditors using recognised procedures, sing up for our ISO 9001 Training now!

Conclusion

The ISO 9001:2015 Monitoring and Measurement Procedure is a cornerstone of Quality Management, offering organisations a systematic approach to assess performance, enhance customer satisfaction, and drive continual improvement. By embracing its key elements and principles, businesses can navigate the path to excellence and ensure sustained success in a competitive landscape.

Understand Auditing techniques to get required objective proof, sign up for our ISO 9001 Lead Auditor Training now!

Frequently Asked Questions

ISO 9001:2015 Clause 7.1.5 covers the requirements for calibration and maintenance of measurement and monitoring equipment. It ensures accuracy and reliability, requiring organisations to establish processes for equipment calibration, verification, and record-keeping.

Monitoring equipment tracks environmental or operational conditions without providing exact measurements, often for analysis over time. Measuring equipment provides precise quantitative data on specific parameters, used for immediate assessment and decision-making, ensuring compliance and quality.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, Blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

The Knowledge Academy offers various ISO 9001 Trainings, including the ISO 9001 Foundation Course, ISO 9001 Lead Auditor Course, and ISO 9001 Internal Auditor Training. These courses cater to different skill levels, providing comprehensive insights into ISO methodologies.

Our ISO & Compliance Blogs cover a range of topics related to ISO 9001, offering valuable resources, best practices, and industry insights. Whether you are a beginner or looking to advance your Quality Managment skills, The Knowledge Academy's diverse courses and informative blogs have got you covered.

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please